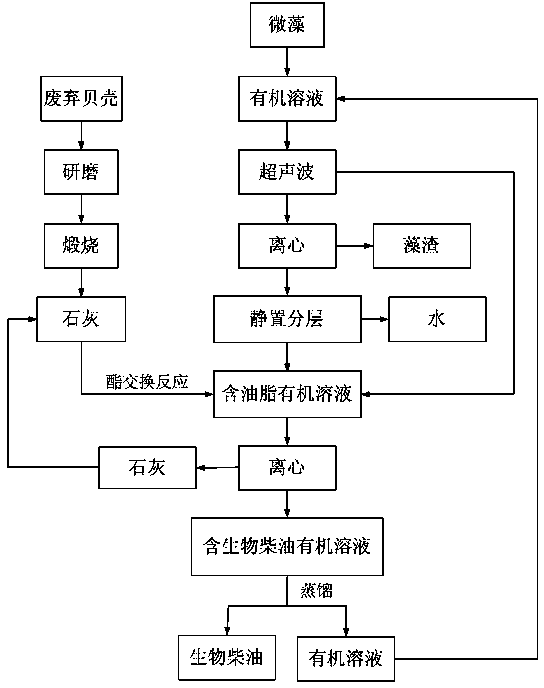

Method for producing wet microalgae biodiesel through calcining shells into lime under assistance of ultrasonic wave

A technology for calcining lime and microalgae organisms, which is applied in the fields of biofuels, petroleum industry, fat oil/fat refining, etc., can solve the problems of little processing and utilization of shell parts, environmental pollution, environmental pollution, etc., so as to reduce production costs and improve extraction. rate, the effect of reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Grind 5 g of discarded mussel shells into powder and calcinate at 900 °C for 4 h in an air atmosphere to obtain lime powder. Add 10g Scenedesmus wets (80% water content) into 40ml chloroform / methanol organic solution (volume ratio 1:1), raise the temperature to 60°C, and act on it at an ultrasonic frequency of 20kHz and a sound energy density of 0.4 W / ml After 1 hour, the algae residue was separated by centrifugation, the liquid phase was allowed to stand for stratification, and the upper layer of the liquid phase was taken to obtain an organic solution containing oil. Add 0.5g of lime into the oil-containing organic solution, set the reaction temperature at 60°C, and act for 1 hour at an ultrasonic frequency of 20kHz and a sound energy density of 0.4 W / ml, then centrifuge the lime and recover it for reuse. The organic solution was removed from the liquid phase by distillation to obtain 0.51 g of crude biodiesel product.

Embodiment 2

[0026] Grind 5 g of discarded mussel shells into powder and calcinate at 900 °C for 4 h in an air atmosphere to obtain lime powder. Add 10g Scenedesmus wets (80% water content) into 50ml chloroform / methanol organic solution (volume ratio 1:1), raise the temperature to 80°C, and act on it at an ultrasonic frequency of 20kHz and a sound energy density of 0.4 W / ml After 0.7 h, the algae residue was separated by centrifugation, the liquid phase was allowed to stand for stratification, and the upper layer of the liquid phase was taken to obtain an organic solution containing oil. Add 0.6g of lime into the oil-containing organic solution, set the reaction temperature to 80°C, and act for 1 hour at an ultrasonic frequency of 20kHz and a sound energy density of 0.4 W / ml, then centrifuge the lime and recover it for reuse. The organic solution was removed from the liquid phase by distillation to obtain 0.63 g of crude biodiesel product.

Embodiment 3

[0028] Grind 5 g of discarded mussel shells into powder and calcinate at 900 °C for 4 h in an air atmosphere to obtain lime powder. Add 10g Scenedesmus hygroides (water content 80%) and 0.6g lime into 50ml chloroform / methanol organic solution (volume ratio 1:1), raise the temperature to 70°C, set the ultrasonic frequency at 20kHz, and the sound energy density at 0.4 W After 1.5 hours of action at the concentration of 1.0 / ml, the algae residue and lime were separated by centrifugation, and the lime was not recovered. The liquid phase was allowed to stand for stratification, and the upper layer of the liquid phase was taken to obtain an organic solution containing biodiesel, and the organic solution was removed by distillation to obtain 0.72 g of crude biodiesel product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com