Self-crosslinking polyvinyl acetate film-forming agent, preparation method and uses thereof

A technology of polyvinyl acetate and film-forming agent, which is applied in the field of self-crosslinking polyvinyl acetate film-forming agent and its preparation field, achieves the effects of strong strand aggregation, improved solvent resistance and good solvent resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

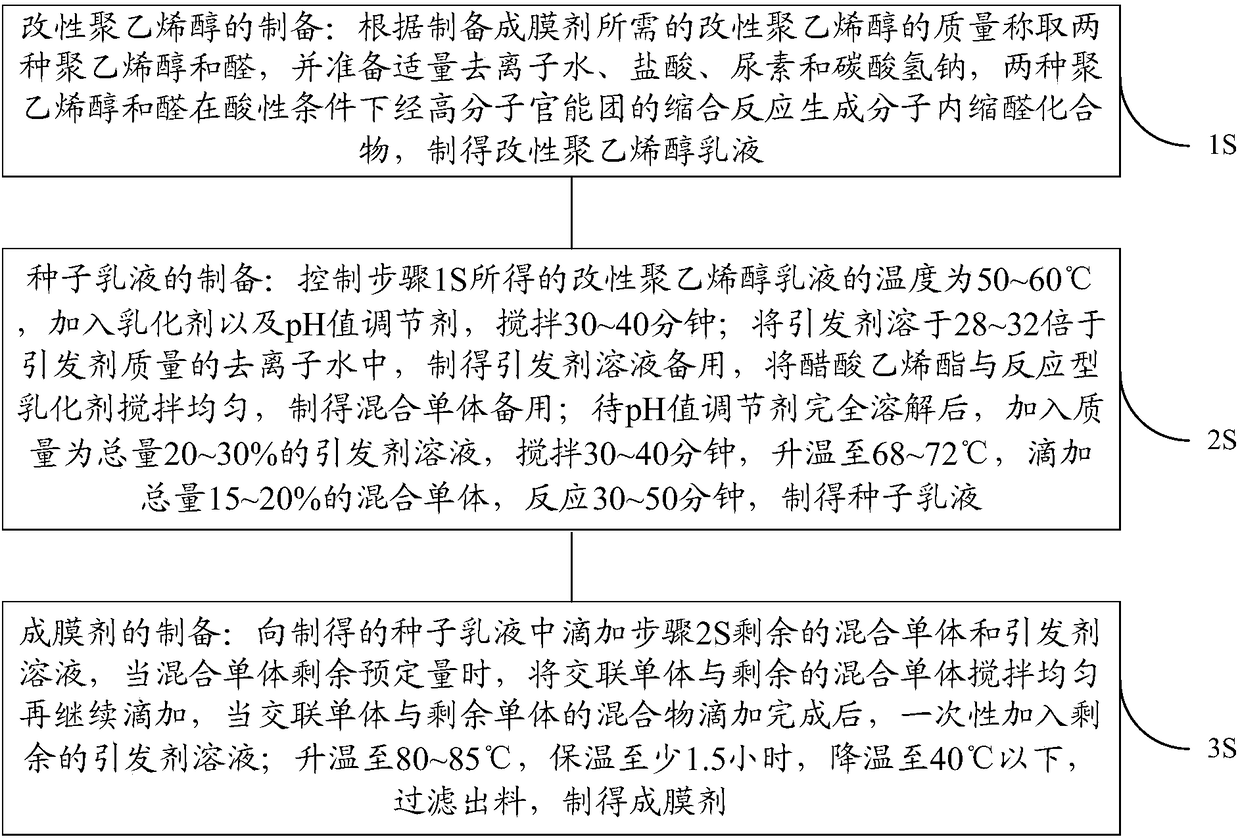

Method used

Image

Examples

Embodiment 1

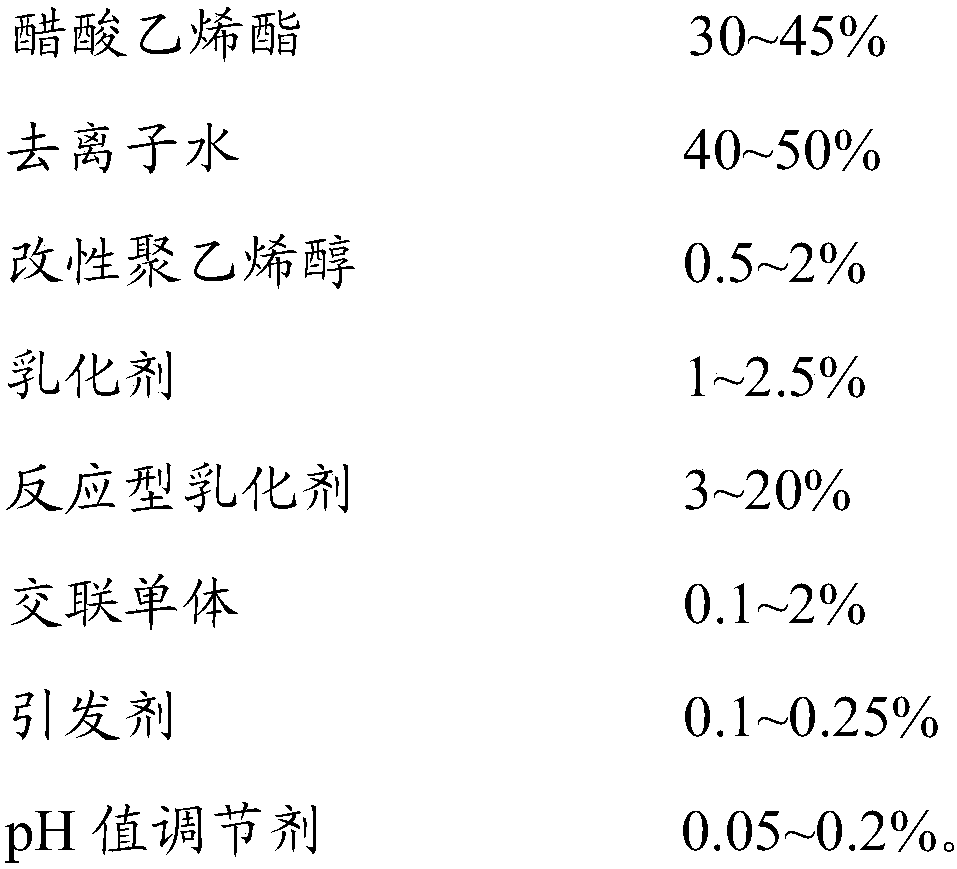

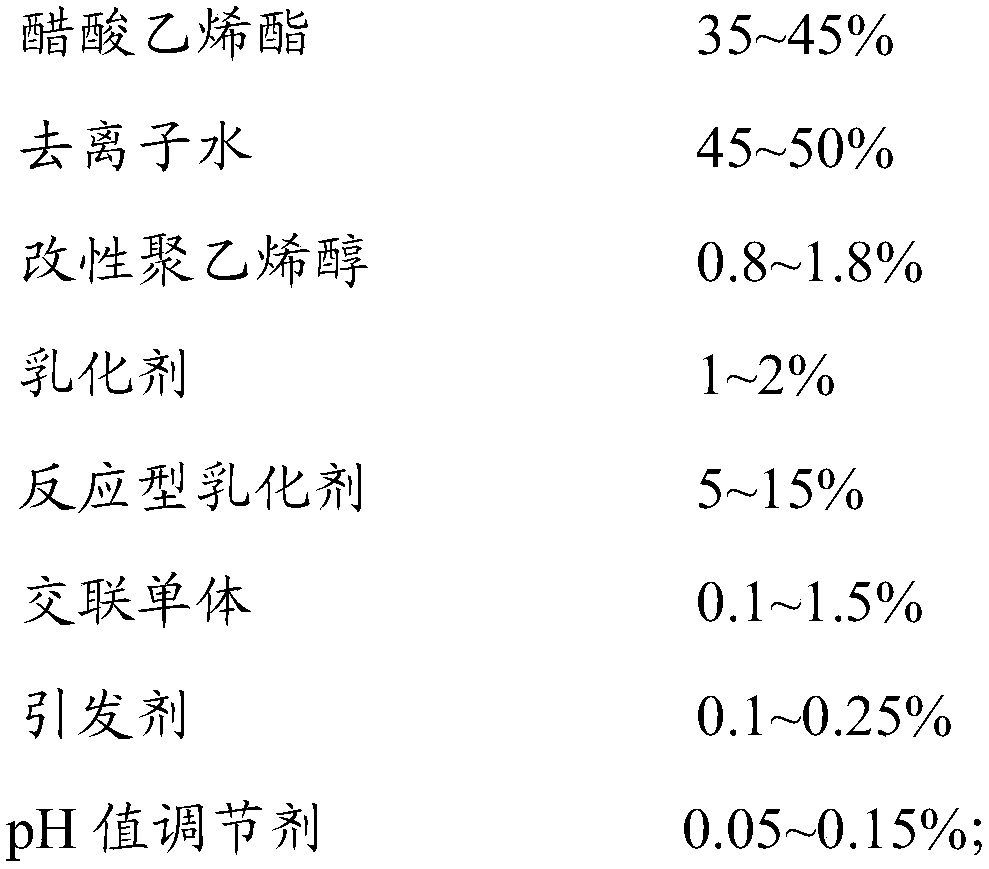

[0062] Weigh each component by mass percentage, wherein, the modified polyvinyl alcohol is made by acetal reaction of two kinds of polyvinyl alcohol and formaldehyde whose grades are BP-20 and BF-17, each component is carried out according to the following steps Preparation of self-crosslinking polyvinyl acetate film-forming agent:

[0063] Preparation of 1S modified polyvinyl alcohol: weigh two kinds of polyvinyl alcohol and aldehyde according to the quality of modified polyvinyl alcohol required for the preparation of film-forming agent, and prepare appropriate amount of deionized water, hydrochloric acid, urea and sodium bicarbonate, specifically Add deionized water and polyvinyl alcohol into a reaction vessel containing a stirrer, a feeder, a reflux condenser and a thermometer, stir and raise the temperature to 90°C to dissolve completely, then cool down to 80°C and add hydrochloric acid to adjust the pH value to 1-2 , start to add formaldehyde dropwise and control the dro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com