High-hardness and high-gloss wood lacquer

A high-hardness, high-gloss technology, applied in the field of wood paint, can solve the problem of high-gloss wood paint losing gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0029] As a preferred embodiment of the present invention, the polyurethane dispersion system is composed of the following materials and parts by weight: 1-5 parts of bissulfonylimide salt, 20-30 parts of acrylate, 20-30 parts of diisocyanate, dihydroxy 10-15 parts of methacrylic acid, 1-10 parts of polyether polyol, 0.1-1 part of dibutyl tin dilaurate, 0.5-3 parts of triethylamine, 40-60 parts of deionized water.

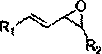

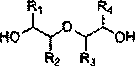

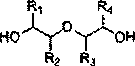

[0030] As a preferred embodiment of the present invention, the structural formula of the bissulfonylimide is:

[0031]

[0032] R1 is an alkane with 1-12 carbons, fluorine atom, benzene ring, pyridine or furan; R2 is an alkane with 1-12 carbons, fluorine atom, benzene ring, pyridine or furan.

[0033] As a preferred embodiment of the present invention, in the structural formula of the bissulfonylimide, M is selected from lithium in alkali metals, sodium, potassium or triethylamine cations in ammonium ions, tetramethylammonium, nitrogen methyl imidazole one or m...

Embodiment 1

[0062] According to the formula of the present invention, 30 parts of polyurethane dispersion system (1 part of bis-sulfonimide salt), 10 parts of nonafluorobutyl acrylate, 6 parts of epoxybutene, 1 part of diol, propylene isophorone 0.05 parts, 0.2 parts of polyether modified polydimethylsiloxane solution, 3 parts of allyl ether sulfonate, 2 parts of propylene glycol methyl ether acetate, 3 parts of photoinitiator, 15 parts of deionized water and mix well A high-gloss wood lacquer with high hardness is obtained. Spray high-hardness high-gloss wood paint on the surface of the wood, level the sprayed wood for 1 hour, dehydrate at a temperature of 50-60°C, UV cure for 20 minutes, keep the temperature at 50-60°C for 30 minutes at a humidity of 30, and then drop to room temperature.

[0063] Measure the hardness H of the paint, the adhesion is 4, and the gloss is semi-matte.

Embodiment 2

[0065] According to the formula of the present invention, 30 parts of polyurethane dispersion system (1.5 parts of bissulfonylimide salt), 10 parts of nonafluorobutyl acrylate, 6 parts of epoxybutene, 1 part of diol, propylene isophorone 0.05 parts, 0.2 parts of polyether modified polydimethylsiloxane solution, 3 parts of allyl ether sulfonate, 2 parts of propylene glycol methyl ether acetate, 3 parts of photoinitiator, 15 parts of deionized water and mix well A high-gloss wood lacquer with high hardness is obtained. Spray high-hardness high-gloss wood paint on the surface of the wood, level the sprayed wood for 1 hour, dehydrate at a temperature of 50-60°C, UV cure for 20 minutes, keep the temperature at 50-60°C for 30 minutes at a humidity of 30, and then drop to room temperature.

[0066] Measure the hardness H of the paint, the adhesion is 3, and the gloss is semi-matte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com