Preparation and liquid preparation method of integrated self-crosslinking thickener modified polymer for fracturing

A fracturing fluid and self-crosslinking technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem that one dose of fracturing fluid cannot be used for multiple purposes, and achieve fast dissolution time, easy use, and good fracturing The effect of milk performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1, preparation of a fracturing liquid emulsion

[0042] The aqueous phase raw material of the fracturing liquid emulsion stock solution is shown in Table 1 below.

[0043] Table 1

[0044] name Quality (g) Acrylamide 210 Sodium acrylate 98 AMPS sodium salt 70 N, N'-dibadone propionlamide ethylenediamine 35 Sperm Appropriate amount Deionized water 987 Molecular weight regulator (quality ratio of sodium formate: urea = 1: 3) 500mg Ion agent 5000mg

[0045] The oil phase feedstock of the fracturing liquid emulsion stock solution is shown in Table 2.

[0046] Table 2

[0047] name Quality (g) No. 10 white oil 510 Span80 60 Tween 60 30

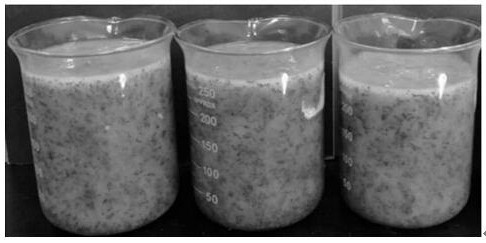

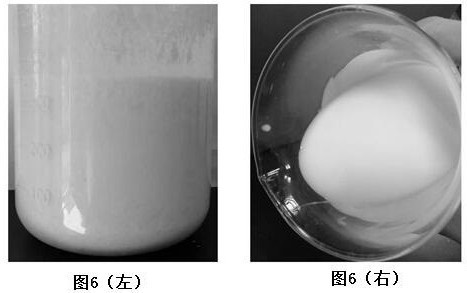

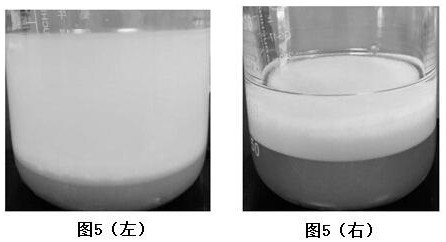

[0048] The feedstock of the oil phase and the aqueous phase is weighed according to the raw materials of Table 1 and Table 2, and the oil phase and the aqueous phase are prepared; mixed with a proportion of the oil phase and the aqueous phase of 3: 7 to th...

Embodiment 2

[0052] Example 2, preparation of a fracturing liquid emulsion

[0053] The hydraulic raw material of the fracturing liquid emulsion stock solution is formulated in Table 4.

[0054] Table 4

[0055]

[0056]

[0057]The oil phase feedstock of the fracturing fluid emulsion stock solution is shown in Table 5.

[0058] table 5

[0059] name Quality (g) No. 10 white oil 510 Span80 60 Tween 60 30

[0060] The feedstock of the oil phase and the aqueous phase is weighed according to the raw material of Table 4 and Table 5, and the oil phase and the aqueous phase are prepared; mixed with a proportion of the oil phase and the aqueous phase of 3: 7 to the viscosity 1000-1200 MPa.s, respectively. After at least 30 minutes of nitrogen passing into a purity of 99.99%, the system temperature drops to 10 ° C, and the composite initiator is ammonium sulfate and sodium bisulfite, and the control reaction temperature does not exceed 40 ° C until the reaction is comp...

Embodiment 3

[0064] Example 3, preparation of a fracturing liquid emulsion

[0065] The hydraulic raw material composition of the fracturing liquid emulsion stock solution is shown in Table 7.

[0066] Table 7

[0067] name Quality (g) Acrylamide 252 Sodium acrylate 112 AMPS sodium salt 126 N, N'-dibadone propionlamide ethylenediamine 42 Sperm Appropriate amount Deionized water 868 Molecular weight regulator (quality ratio of sodium formate: urea = 1: 3) 500mg Ion agent 5000mg

[0068] The oil phase feedstock of the fracturing liquid emulsion stock solution is formulated as follows 8.

[0069] Table 8

[0070] name Quality (g) No. 10 white oil 510 Span80 60 Tween 60 30

[0071] The raw materials of the oil phase and the aqueous phase are weighed according to the raw materials of Table 7 and Table 8, and the oil phase and the aqueous phase are prepared; mixed with a proportion of the oil phase and the aqueous pha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com