A kind of preparation method of polygonal clathrate siloxane supercritical carbon dioxide thickener

A technology of carbon dioxide and siloxane, which is applied in the direction of chemical instruments and methods, drilling compositions, bulk chemical production, etc., can solve problems such as large amount of solvent consumption, preparation cost or environmental pollution, unfavorable industrial application, etc., and achieve improvement Miscibility and solubility, improved miscibility and thickening ability, and the effect of convenient purchase route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

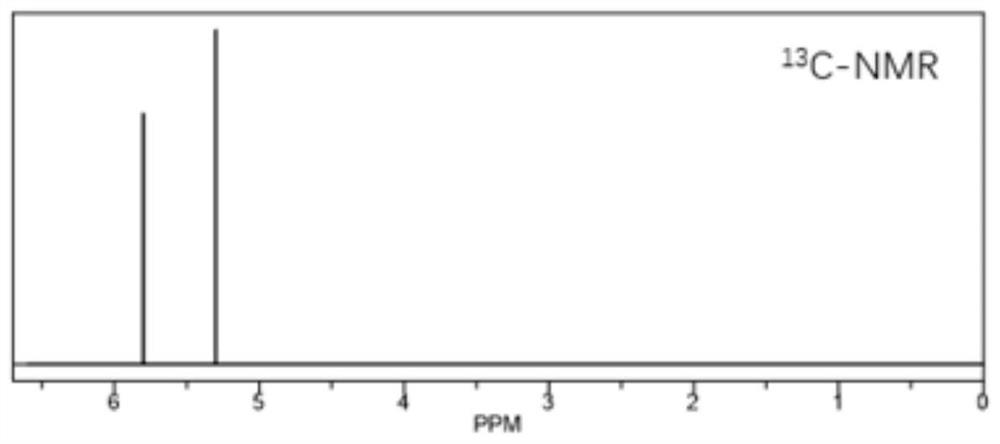

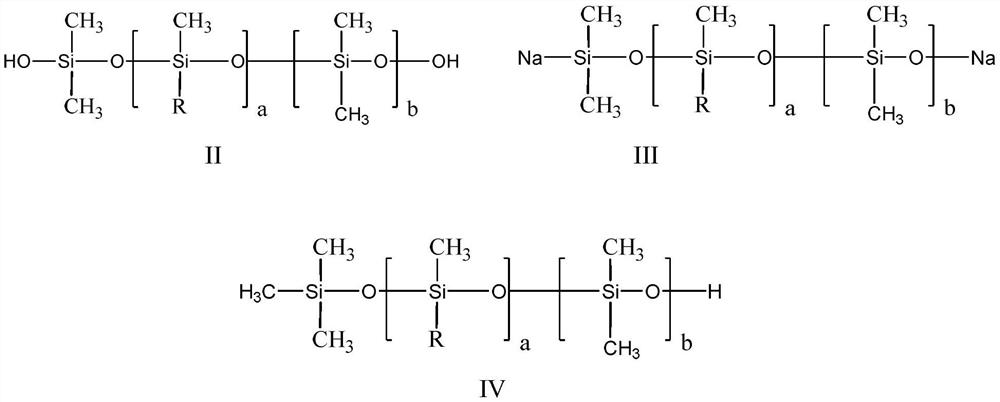

[0065] A preparation method of a multi-terminal branched siloxane supercritical carbon dioxide thickener, comprising the following steps:

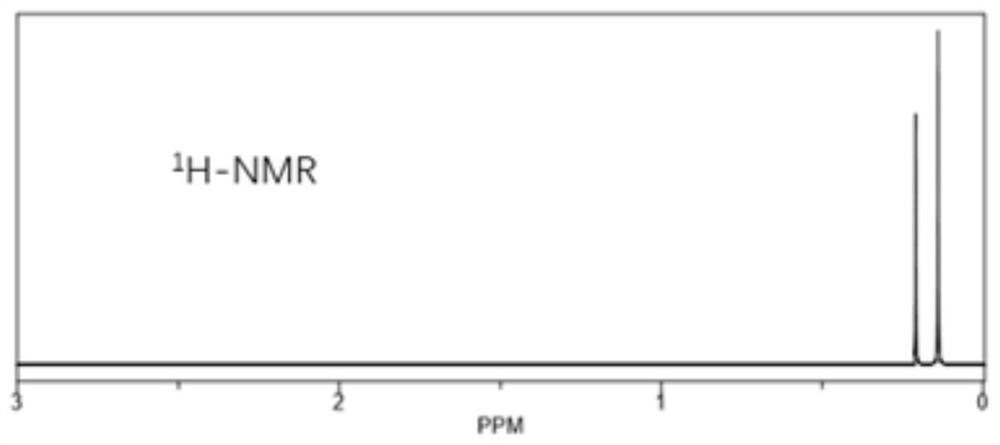

[0066] (1) Preparation of monohydrogen-terminated linear siloxane

[0067] 105g 1,21-hydroxypolysiloxane, 124mL cyclohexane, 6.59g sodium silanolate were added to a 500ml dry three-necked flask equipped with a stirrer, a nitrogen pipe and a thermometer, and the increase rate was increased at 2.6°C / min. After the temperature reaches 75°C, the reaction is carried out for 8.5 hours; the mixture is cooled to room temperature and suction filtered to remove impurities to obtain double-ended sodium-terminated siloxane (1,21-sodium polysiloxane). The prepared 1,21-sodium polysiloxane was poured into another 250mL glass flask, and 9.73g of dimethyl monohydrochlorosilane was reacted at -15°C for 20h, at a vacuum of 0.05MPa and a temperature of 78 Impurities were removed under the condition of ℃ to obtain 108 g of monohydrogen terminated linear silo...

Embodiment 2

[0076] As described in Example 1, the operation steps are the same, the difference is that the cage-shaped stereocyclosiloxane used in step (2) is a hexahedral all-square stereocyclocyclosiloxane. The structural formula of the obtained product is as follows (a=13, b=7):

[0077] R1 is

Embodiment 3

[0079] As described in Example 1, except that 1,21-hydroxy-2-naphthyl-siloxane was added in step (1). The structural formula of the obtained product is as follows (a=13, b=7):

[0080] R 1 for

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com