Resist underlayer film forming composition containing compound having hydantoin ring

A technology of resist lower layer and photoresist layer, which is applied in the direction of organic chemistry, photographic plate-making process of pattern surface, photosensitive material used in optomechanical equipment, etc., and can solve the problem that resist pattern cannot be formed , to achieve the effects of reduced sublimation content, thermal sublimation suppression, and high dry etching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

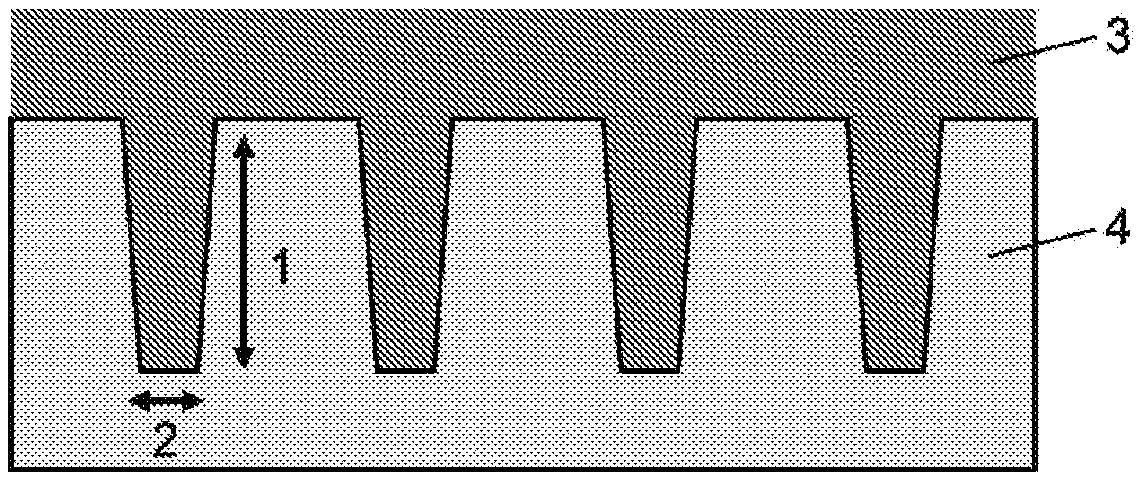

Image

Examples

Embodiment

[0072] Hereinafter, specific examples of the resist underlayer film-forming composition of the present invention will be described using the following synthesis examples and examples, but the present invention is not limited thereto.

[0073] The apparatus etc. used for the measurement of the weight average molecular weight of the compound obtained in the following synthesis example are shown.

[0074] Device: HLC-8320GPC manufactured by Tosoh Corporation)

[0075] GPC column: KF-803L, KF-802, KF-801 (manufactured by Showa Denko Co., Ltd.)

[0076] Column temperature: 40°C

[0077] Solvent: THF

[0078] Flow: 1.0mL / min

[0079] Injection volume: 50μL

[0080] Measurement time: 35 minutes

[0081] Standard sample: Polystyrene (manufactured by Showa Denko Co., Ltd.)

[0082] Detector: RI

[0083]

[0084] Under a nitrogen atmosphere, 30.0 g of triglycidyl isocyanurate (manufactured by Nissan Chemical Industries, Ltd.), 1-hydroxymethyl-5,5-dimethylhydantoin (Tokyo Kasei...

Embodiment 2

[0095] 0.017 g of 5-sulfosalicylic acid (manufactured by Tokyo Chemical Industry Co., Ltd.), containing 0.017 g of the compound obtained in Synthesis Example 1 above, was mixed with 3.42 g of a solution (the solvent used in the synthesis was PGME) containing 0.51 g of the compound obtained in Synthesis Example 1 above. 0.63 g of a solution of 0.18 g of the compound obtained in 2 (the solvent is PGME used during synthesis), and 0.00051 g of a surfactant (DIC Co., Ltd., trade name: R-30N), 14.06 g of PGME, and 1.88 g of PGMEA, A solution containing 3.54% by mass of mixing components other than the solvent was prepared. This solution was filtered using a polytetrafluoroethylene microfilter with a pore diameter of 0.2 μm to prepare a composition for forming a resist underlayer film.

Embodiment 3

[0097] 1,3,4,6-Tetrakis(methoxymethyl)glycoluril (Mitsui Cytech Co., Ltd. ), product name: Paudarlink 1174) 0.44 g, 5-sulfosalicylic acid (manufactured by Tokyo Chemical Industry Co., Ltd.) 0.22 g, 10.94 g of a solution containing 3.09 g of the compound obtained in Synthesis Example 2 above (solvent: PGME used during synthesis), and surfactant (DIC Co., Ltd., trade name: R-30N) 0.0088g, PGME245.22g, and PGMEA33.74g, made a solution of 3.60% by mass of the mixed components except the solvent . This solution was filtered using a polytetrafluoroethylene microfilter with a pore diameter of 0.2 μm to prepare a composition for forming a resist underlayer film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com