Range hood with self-cleaning function

A range hood, self-cleaning technology, applied in the directions of removing oil fume, cleaning methods and utensils, cleaning methods using liquid, etc. The effect of prolonged contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

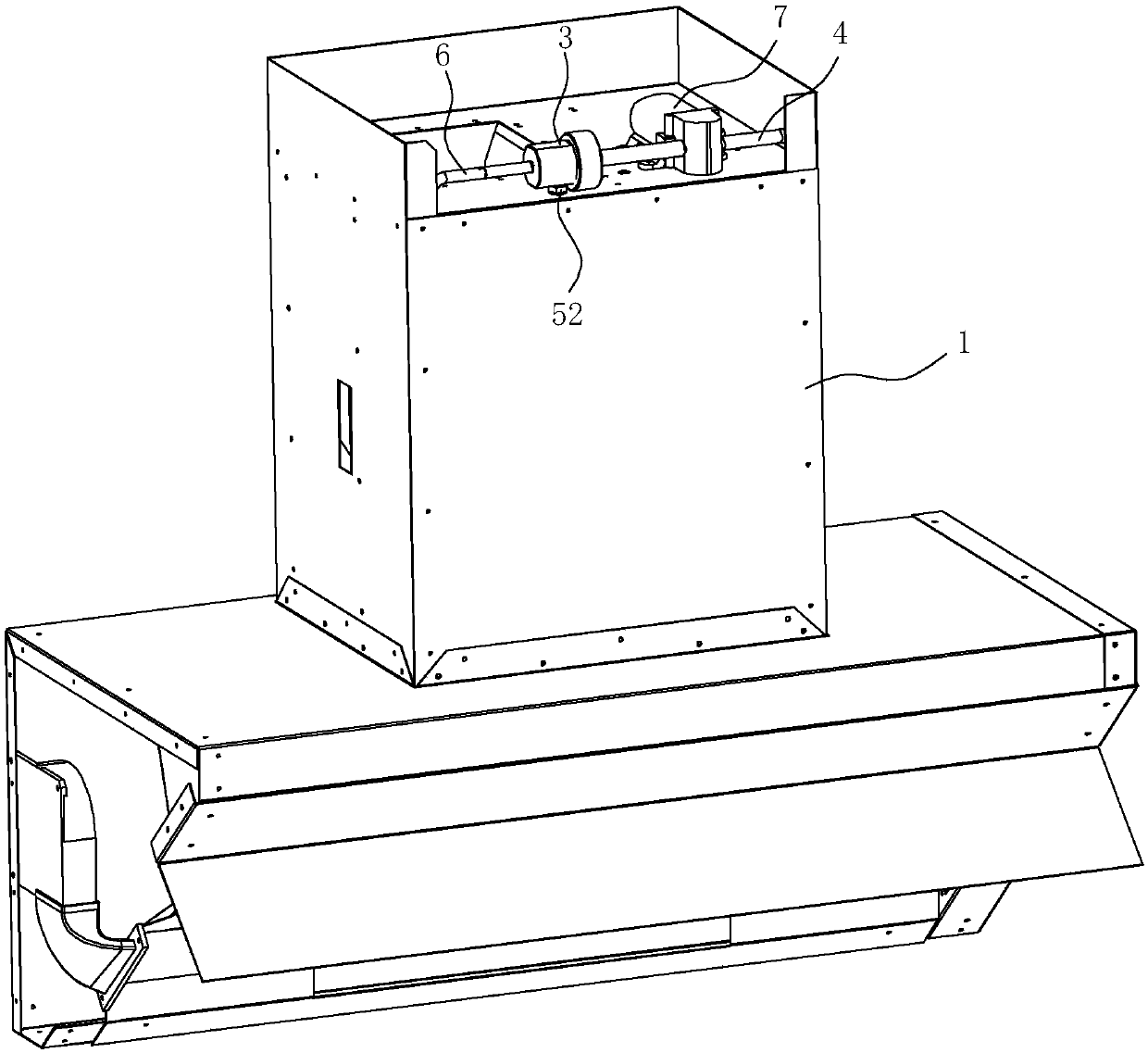

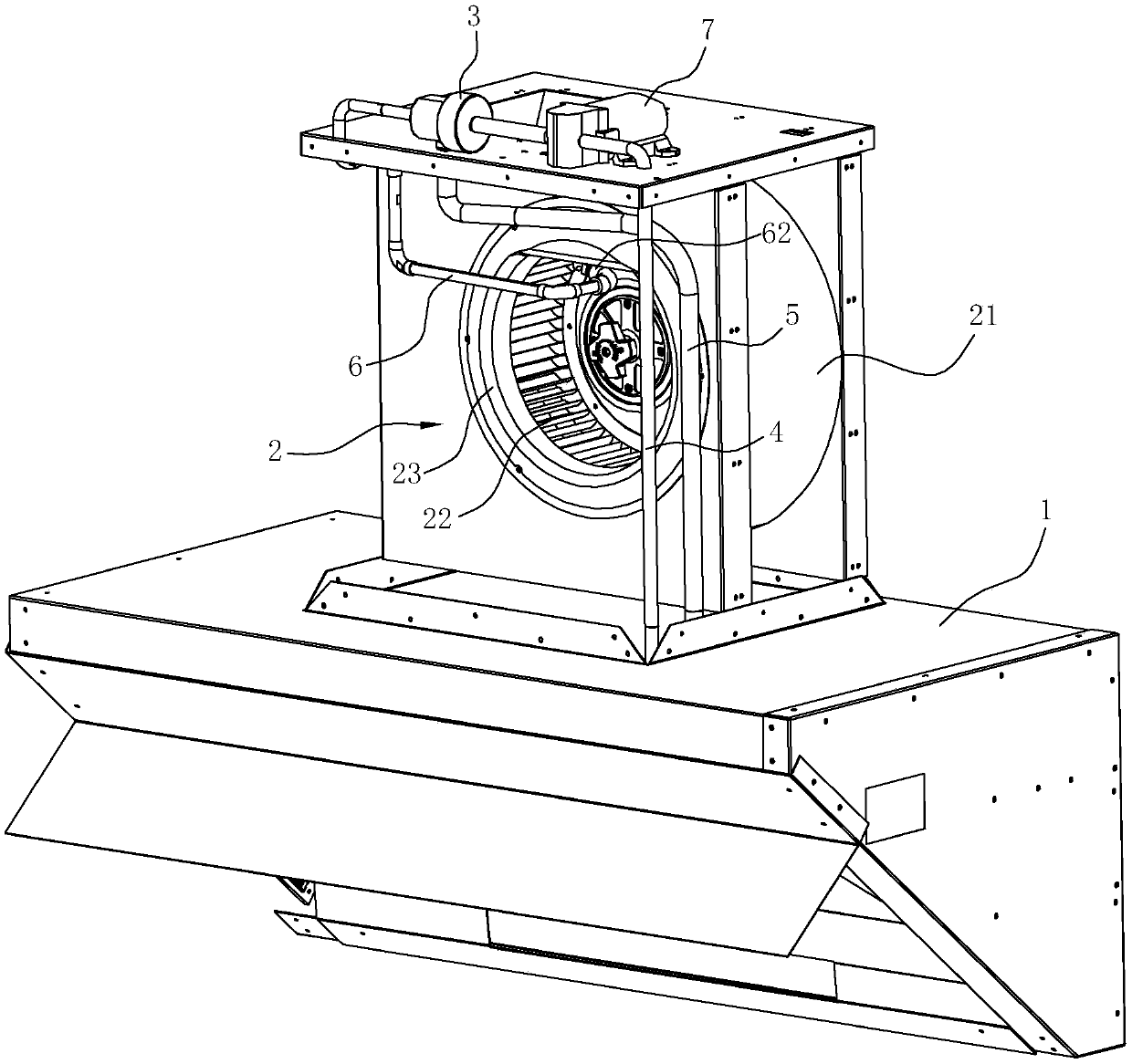

[0023] Such as Figure 1-8 As shown, the range hood with self-cleaning function of this embodiment includes a casing 1, a fan 2 and a cleaning assembly, the fan 2 is arranged in the casing 1, and the fan 2 of this embodiment is a centrifugal fan with a volute 21 and a The impeller 22 in the volute 21 and the air inlet 23 of the fan 2 are arranged forward. The cleaning component is arranged in the casing 1 and can spray cleaning medium into the fan 2 .

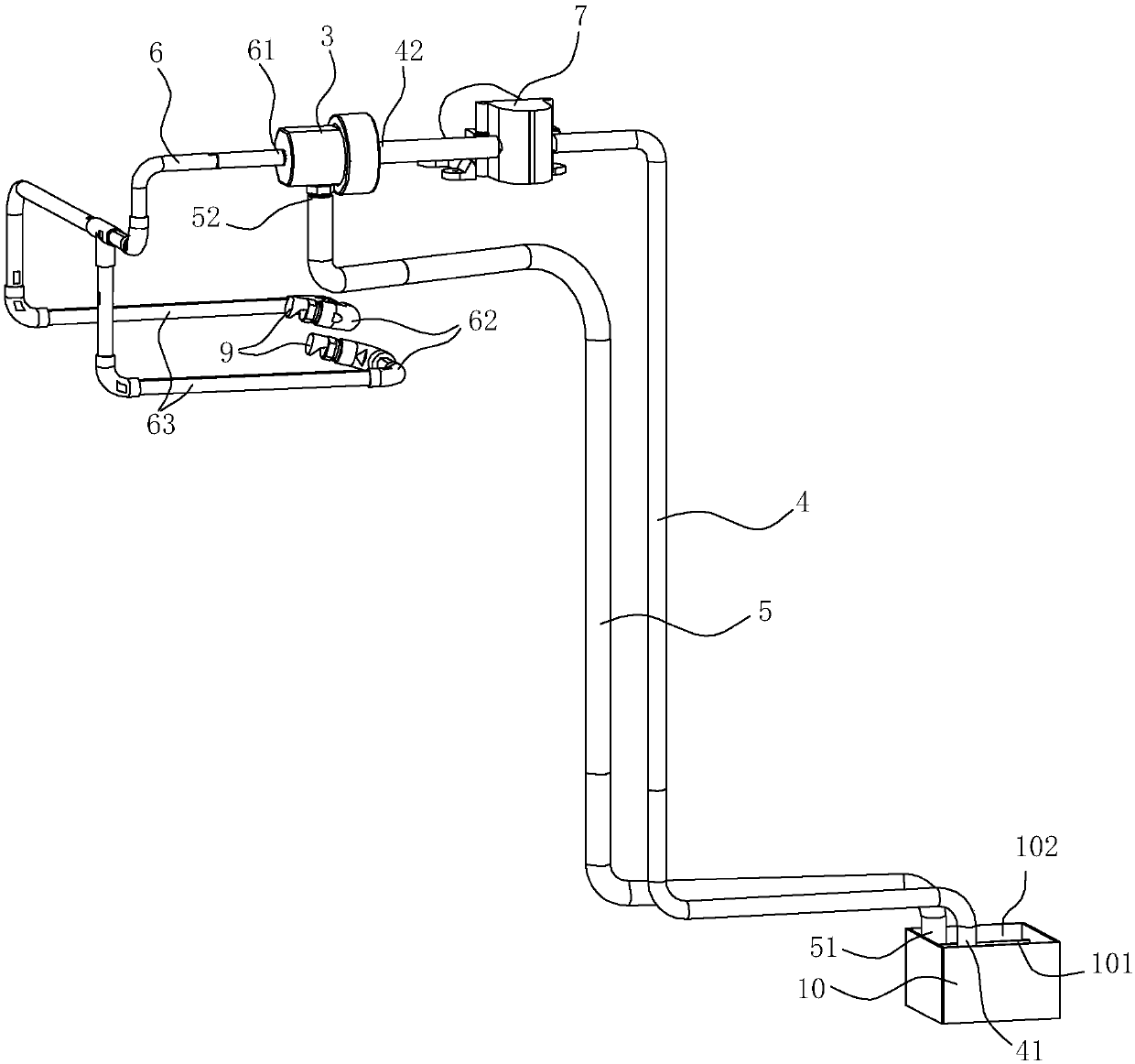

[0024] In this embodiment, the cleaning assembly includes a foaming seat 3, a first liquid guide tube 4, a second liquid guide tube 5, a third liquid guide tube 6 and a driving member 7, and the inside of the foaming seat 3 is hollow to form a mixing chamber 30 , the first liquid guide tube 4 has a first port 41 for water supply input, the second port 42 of the first liquid guide tube 4 commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com