Enzyme microorganism liquid compound fertilizer and preparation method thereof

An enzyme bacteria and compound fertilizer technology, applied in the preparation of liquid fertilizers, organic fertilizers, nitrogen fertilizers, etc., can solve the problems of weak efficacy and cumbersome preparation methods, and achieve the effects of strong water absorption, increased nutrient content, and small shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

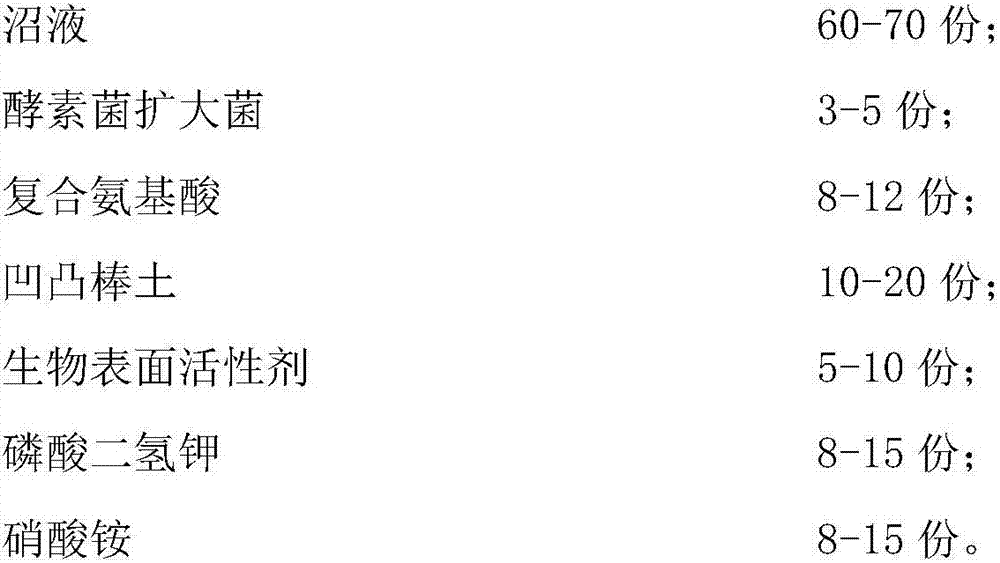

[0023] A kind of enzyme bacterium liquid compound fertilizer in the present embodiment is made up of following components by weight:

[0024]

[0025] The specific steps of the preparation method are as follows: according to the above formula by weight, 10 parts of compound amino acids, 12 parts of potassium dihydrogen phosphate and 12 parts of ammonium nitrate are added to 70 parts of biogas slurry fermented from the mixture of plant and edible fungus waste residue and stirred Dissolving and mixing, the stirring speed is 1000r / min, then add 8 parts of cyclolipopeptide biosurfactant to emulsify for 0.5h, then add 15 parts of attapulgite with a particle size of 150 mesh, ball mill and mix at a ball milling speed of 1000r / min for 1.5h, Finally, add 5 parts of enzyme bacteria expansion bacteria including bacteria, actinomycetes, yeast and filamentous bacteria, and ferment for 7 hours at a temperature of 25° C. to obtain the enzyme bacteria liquid compound fertilizer.

Embodiment 2

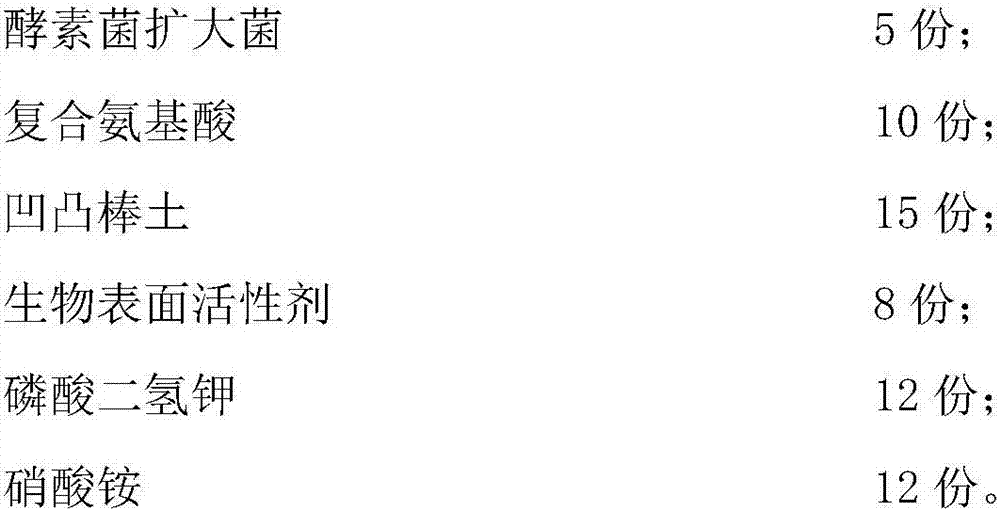

[0027] The preparation method of this embodiment is the same as that of Example 1, except that a kind of ferment bacterium liquid compound fertilizer in the present embodiment is made up of following components by weight:

[0028]

Embodiment 3

[0030] The preparation method of this embodiment is the same as that of Example 1, except that a kind of ferment bacterium liquid compound fertilizer in the present embodiment is made up of following components by weight:

[0031]

[0032]

[0033] Get the liquid compound fertilizer that above-mentioned embodiment 1 prepares, adopt per mu 10L, after diluting with water 300 times, spray on the root of plant. The enzyme bacteria liquid compound fertilizer prepared by the above method was stored at room temperature for 2-3 months without precipitation or stratification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com