Biodegradable polymer material compatibilized and blended by lignocellulose and preparation method thereof

A technology for lignocellulose and polymer materials, which is applied in the field of lignocellulose compatibilizing blending and degrading polymer materials and its preparation, can solve the problems of poor mechanical properties, poor compatibility of biological blending materials, etc. Capacitance improvement, boost effect, dosage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of preparation method of macromolecule compatibilizer polycaprolactone-maleic anhydride block copolymer: place 250ml there-necked flask with strictly dried maleic anhydride 15 g and ε-caprolactone 70 g, then decompress , Tong N 2 , repeat the operation 3 times, stir under the protection of nitrogen, heat the oil bath to 130 ° C, until the material is completely dissolved, add 2.25g of the initiator Sn(Oct) 2 , the reaction stopped after 12 hours. The reaction product was diluted with chloroform, precipitated with anhydrous methanol, filtered and dried to obtain a yellow solid crude product.

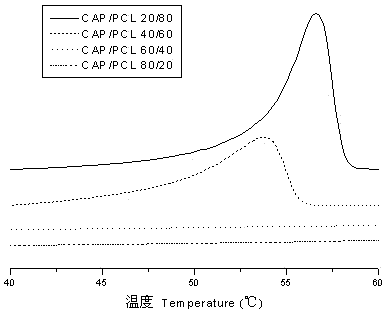

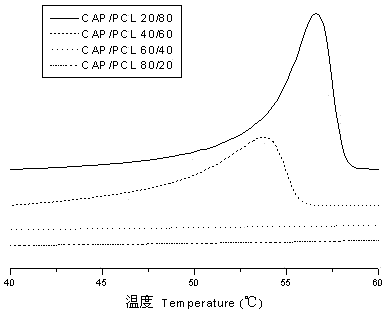

[0046] The cellulose acetate and polycaprolactone were mixed according to the mass ratio of 60 / 40 to obtain a resin mixture, and the CTW50 MiniLab conical twin-screw extrusion equipment of German HAAKE Company was used for melt extrusion of the blended material. At 130~250°C, put the resin mixture and the macromolecular compatibilizer into the silo of the twin-screw extrud...

Embodiment 2

[0048] Place strictly dried maleic anhydride 20 g and ε-caprolactone 90 g in a 250 ml three-necked flask, then depressurize and pass through N 2 , repeat the operation 3 times, stir under the protection of nitrogen, heat the oil bath to 130 ° C, until the material is completely dissolved, add 1.5g of initiator Sn(Oct) 2 , the reaction stopped after 16 hours. The reaction product was diluted with chloroform, precipitated with anhydrous methanol, filtered and dried to obtain a yellow solid crude product.

[0049] The cellulose acetate and polycaprolactone were mixed according to the mass ratio of 60 / 40 to obtain a resin mixture, and the CTW50 MiniLab conical twin-screw extrusion equipment of German HAAKE Company was used for melt extrusion of the blended material. At 130~250°C, put the resin mixture and the macromolecular compatibilizer into the silo of the twin-screw extruder, force feeding, and the extruded product is air-cooled and pelletized to form resin pellets.

Embodiment 3

[0051] Place strictly dried maleic anhydride 20 g and ε-caprolactone 90 g in a 250 ml three-necked flask, then depressurize and pass through N 2 , repeat the operation 3 times, stir under the protection of nitrogen, heat the oil bath to 130 ° C, until the material is completely dissolved, add 1.5g of the initiator Sn(Oct) 2 , the reaction stopped after 16 hours. The reaction product was diluted with chloroform, precipitated with anhydrous methanol, filtered, and dried to obtain a crude yellow solid polycaprolactone-maleic anhydride block copolymer.

[0052] The cellulose acetate and polycaprolactone were mixed in a mass ratio of 50 / 50 to obtain a resin mixture, and the CTW50 MiniLab conical twin-screw extrusion equipment of Germany HAAKE Company was used for melt extrusion of the blended material. At 130~250°C, put the resin mixture and compatibilizer into the silo of the twin-screw extruder, force feed, and the extruded product is air-cooled and pelletized to form resin pell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com