Multi-crosslinking modified nuclear-shell structure room-temperature self-crosslinking acrylic emulsion and preparation method thereof

A technology of self-crosslinking acrylic acid and core-shell structure is applied in the field of multi-crosslinking modified core-shell structure room temperature self-crosslinking acrylic emulsion and its preparation field, which can solve the problem of poor storage and transportation stability of coatings, affecting coating film performance, and high cost. problem, to achieve the effect of excellent adhesion, reduced water absorption, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

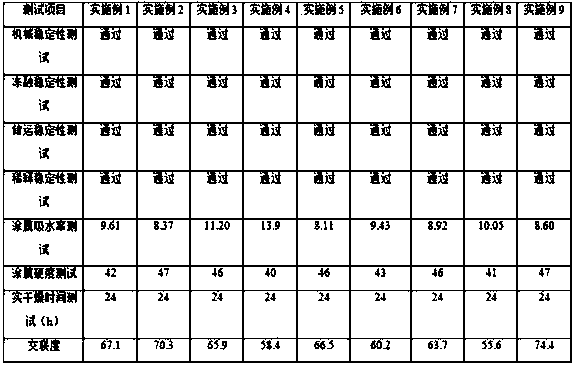

Examples

Embodiment 1

[0024] A room temperature self-crosslinking acrylic acid emulsion with core-shell structure modified by multiple crosslinking, comprising the following components by weight:

[0025] Vinyl soft monomer: butyl acrylate and isooctyl acrylate, accounting for 18 and 7 parts respectively;

[0026] Vinyl hard monomer: methyl methacrylate and styrene, accounting for 10 and 5 parts respectively;

[0027] Functional monomers: methacrylic acid, maleic anhydride, and hydroxyethyl methacrylate, accounting for 1.5, 1, and 2 parts respectively;

[0028] Cross-linking monomers: diacetone acrylamide, acetoxyethyl methacrylate, N-methylol acrylamide, accounting for 2, 2, and 1 parts respectively;

[0029] Cross-linking agent: adipic acid dihydrazide, 1.5 parts;

[0030] Adhesion promoter: methacrylate based alkoxy phosphate, 1 part;

[0031] Emulsifier: allyloxy nonylphenol polyoxyethylene ether monophosphoric acid, dimethyl vinyl phosphate, accounting for 1 and 1 part respectively;

[003...

Embodiment 2

[0042] A room temperature self-crosslinking acrylic acid emulsion with core-shell structure modified by multiple crosslinking, comprising the following components by weight:

[0043]Vinyl soft monomer: butyl methacrylate, butyl acrylate, isooctyl acrylate, and isooctyl methacrylate, accounting for 6, 13, 7, and 2 parts respectively;

[0044] Vinyl hard monomers: methyl methacrylate, methyl acrylate, acrylonitrile, and styrene, accounting for 7, 4, 2, and 4 parts respectively;

[0045] Functional monomers: acrylic acid, methacrylic acid, maleic anhydride, and hydroxyethyl methacrylate, accounting for 1, 0.5, 0.5, and 1 part respectively;

[0046] Cross-linking monomers: diacetone acrylamide, acetoxyethyl methacrylate, N-methylol acrylamide, accounting for 2.5, 1, and 1 parts respectively;

[0047] Cross-linking agent: adipic acid dihydrazide, 2 parts;

[0048] Adhesion Promoter: Methacrylate Alkoxy Phosphate, 2 parts;

[0049] Emulsifier: allyloxy nonylphenol polyoxyethylene...

Embodiment 3

[0060] A room temperature self-crosslinking acrylic acid emulsion with core-shell structure modified by multiple crosslinking, comprising the following components by weight:

[0061] Vinyl soft monomer: butyl methacrylate, butyl acrylate, and isooctyl acrylate, accounting for 7, 15, and 2 parts respectively;

[0062] Vinyl hard monomers: methyl methacrylate, methyl acrylate, acrylonitrile, and styrene, accounting for 7, 4, 2, and 4 parts respectively;

[0063] Functional monomers: acrylic acid, maleic anhydride, and hydroxyethyl methacrylate, accounting for 1, 1, and 1 part respectively;

[0064] Cross-linking monomers: diacetone acrylamide, acetoxyethyl methacrylate, N-methylol acrylamide, accounting for 3, 1, and 1 parts respectively;

[0065] Cross-linking agent: adipic acid dihydrazide, 3 parts;

[0066] Adhesion Promoter: Methacrylate Alkoxy Phosphate, 2 parts;

[0067] Emulsifier: allyloxy nonylphenol polyoxyethylene ether, dimethyl vinyl phosphate, accounting for 2 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com