Method for compatibilizing PLA/PBAT alloy

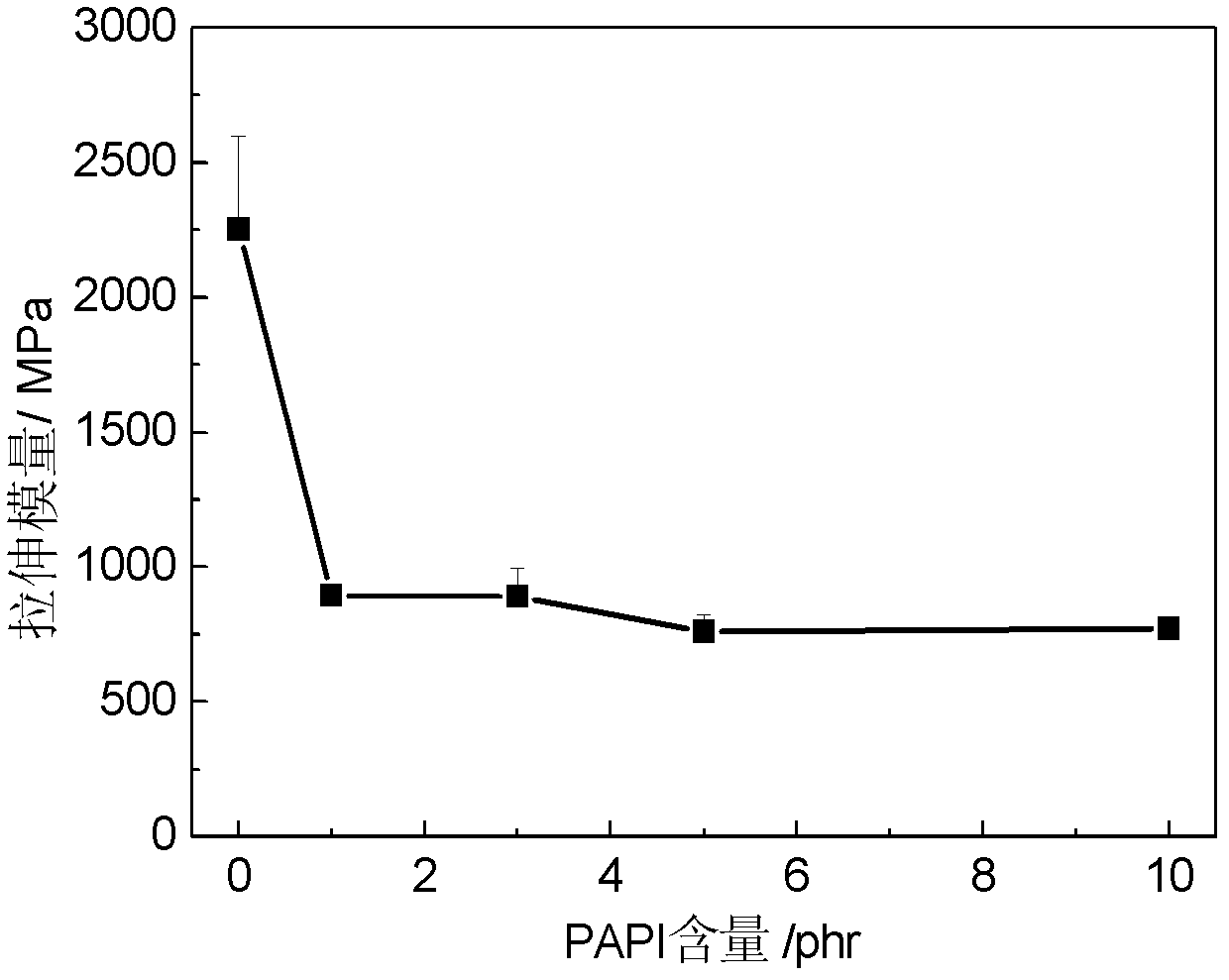

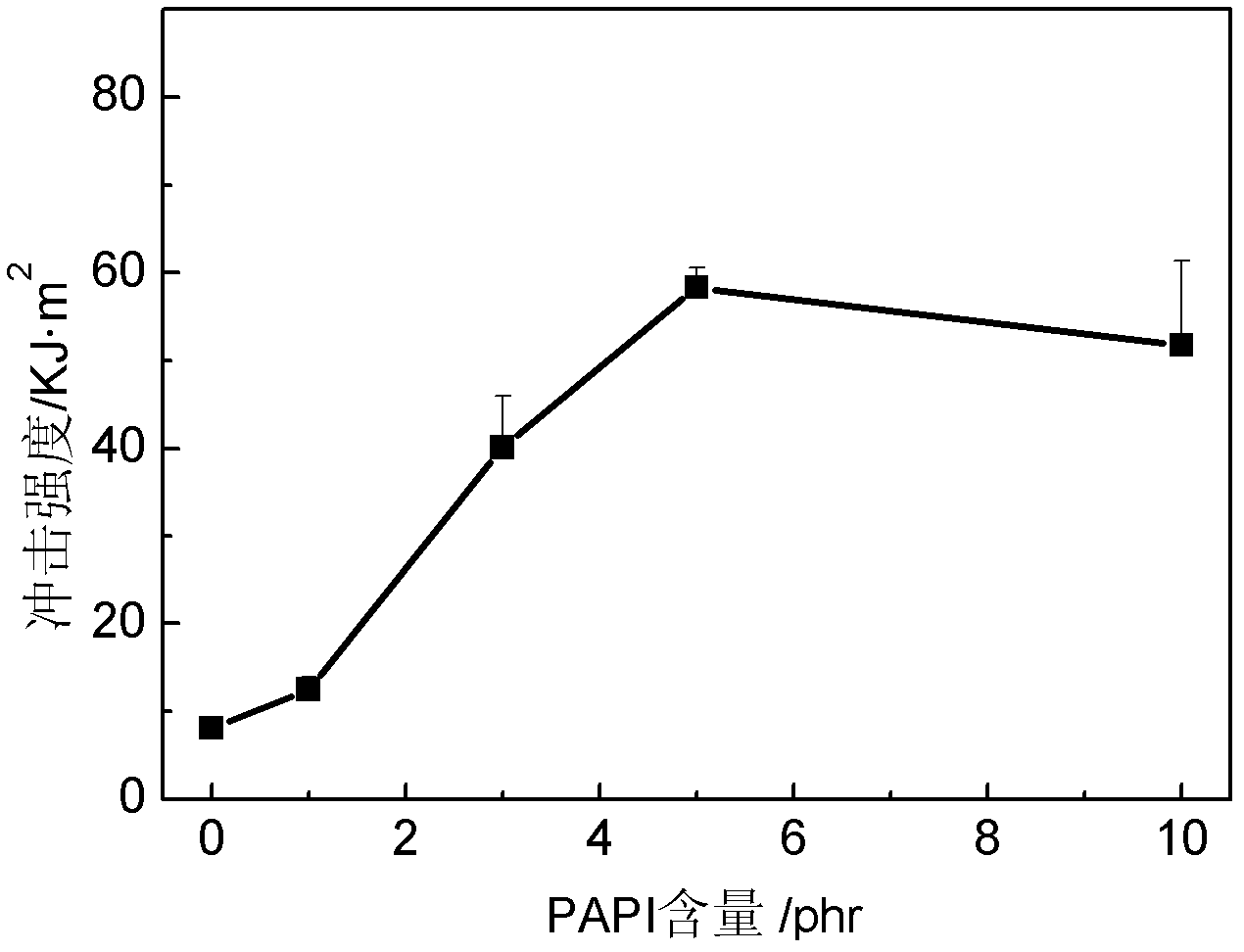

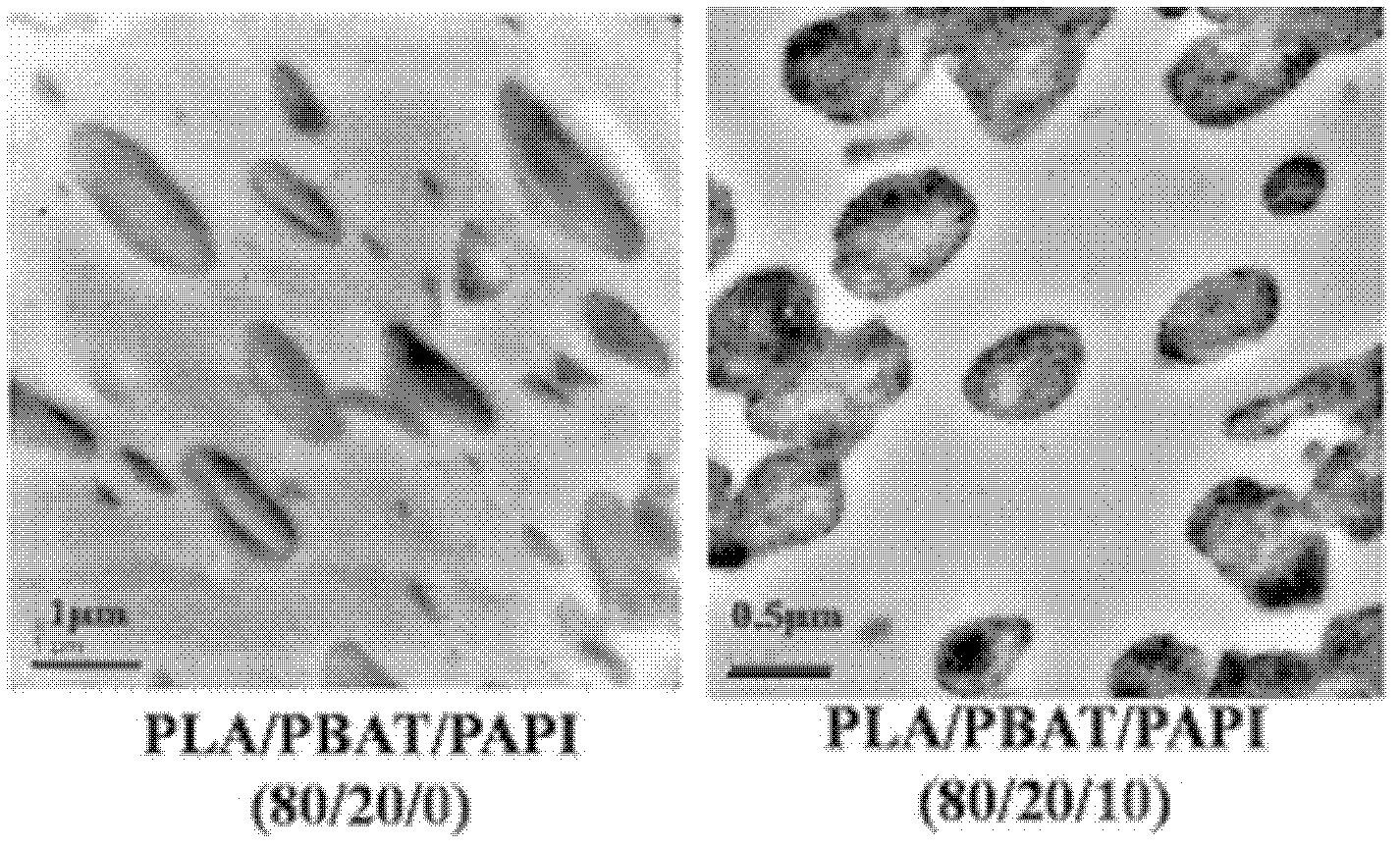

A technology of alloy and compatibilizer, which is applied in the field of compatibilizing PLA/PBAT alloy, can solve problems such as unsatisfactory results, and achieve the effects of improving two-phase compatibility, reducing size, and better comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The dried PLA and PBAT resins were thoroughly mixed in a certain weight ratio, and then added to a Haake torque rheometer (Rheocord 90, HAAKE Mess-Technic GmbH, Germany) for melt blending. When the PLA / PBAT blend Immediately after melting started, a certain amount of PAPI was added to the molten blend. The mixing temperature is 170° C., the mixing time is 10 minutes, and the rotor speed is 50 rpm.

[0028] Use a flat vulcanizer (XLB-D, Zhejiang Huzhou Hongtu Machinery Co., Ltd.) to hot-press the prepared PLA / PBAT / PAPI blend at 170°C and 10MPa, preheating time is 10min, hot-pressing for 5min, cold-pressing 15min. The thickness of the film is around 200 μm (for infrared characterization), and the thickness of the flakes is 1 mm and 3 mm, respectively.

[0029] According to the infrared spectrum of the blend, at 1740cm -1 The absorption peak at corresponds to the stretching vibration peak of -CO; 1515, 1536cm -1 The absorption peak at corresponds to the -NH-C=O stretch...

Embodiment 2

[0033] A method for compatibilizing PLA / PBAT alloys, adding compatibilizer 4,4'-diphenylmethane diisocyanate (MDI) after melting PLA / PBAT alloys, and blending at 140°C for 60 minutes to obtain a modified blend material, the consumption of MDI is 90wt% of the total mass of PLA / PBAT.

Embodiment 3

[0035] A kind of method of compatibilization PLA / PBAT alloy, after PLA / PBAT alloy melting, add compatibilizer dicyclohexylmethane diisocyanate (H 12 MDI), blended at 220°C for 5min to obtain the modified blend, H 12 The amount of MDI is 0.001wt% of the total mass of PLA / PBAT.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com