Preparation method of amphipathic non-spherical particles

A non-spherical, amphiphilic technology, applied in the field of preparation of amphiphilic non-spherical particles, can solve the problem of singleness, and achieve the effect of simple operation and mild experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

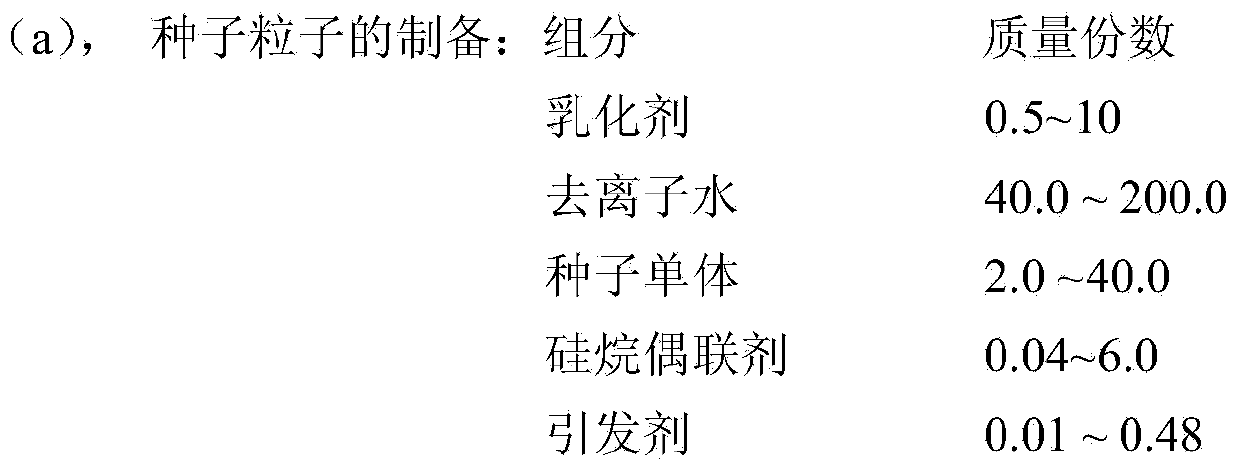

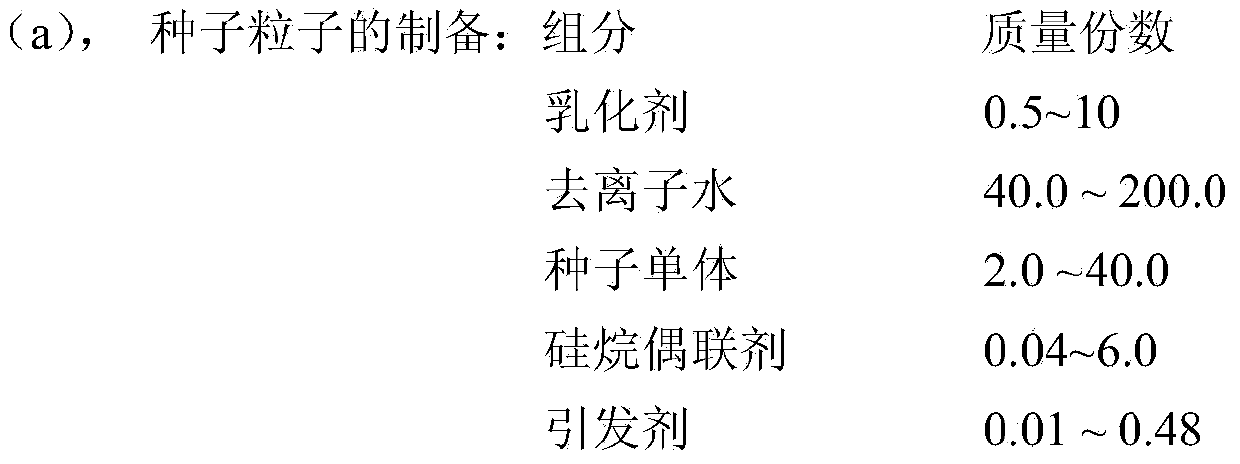

[0022]

[0023] According to the above ratio, add 2.0g emulsifier sodium lauryl sulfate and 100.0g deionized water into the reactor, add 2M hydrochloric acid to adjust the pH of the system to 2.5, then add 10.0g seed monomer styrene, 0.5 g silane coupling agent 3-(methacryloyloxy)propyltrimethoxysilane, 0.1g initiator azobisisobutyronitrile, start stirring to form an O / W emulsion, and keep stirring the system at 30°C for 10 hours , so that the silane coupling agent undergoes a sol-gel process at the phase interface, and then the system is raised to 70 ° C, nitrogen gas is introduced, reflux is condensed, and polymerization is carried out for 8 hours, that is, a silica layer with a hydrophilic shell is obtained. The core is a seed particle of polystyrene;

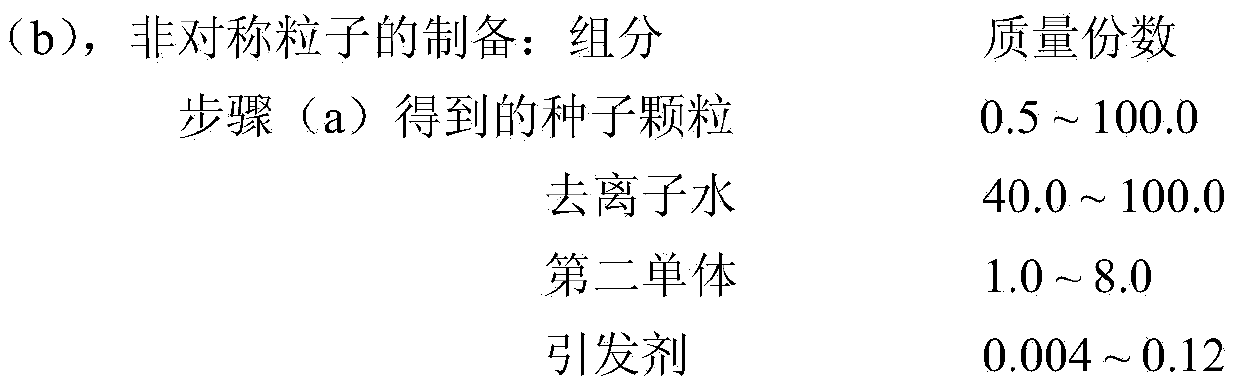

[0024]

[0025] Add 80.0 g of deionized water to the seed emulsion (10.5 g) obtained in step (a). After ultrasonic dispersion, start stirring, add 3.0 g of the second monomer methyl methacrylate, and nitrogen gas is in...

Embodiment example 2

[0029] In the implementation case 2, the amount of the emulsifier is increased to 5.0 g, and the rest of the implementation process is the same as the implementation case 1.

[0030] Increasing the amount of emulsifier will form more and smaller micelles, resulting in smaller particles.

Embodiment example 3-5

[0032] In Example 3-5, the seed monomer is changed to acrylonitrile, the second monomer is styrene, tert-butyl acrylate, and α-methylstyrene, and the rest of the implementation process is the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com