Mochi bread premix powder with good freeze thawing stability, mochi bread and production thereof

A freeze-thaw stability, mochi bread technology, applied in dough processing, baking, baked food, etc., can solve the problems of poor rise, low occupancy, hard taste, etc., to increase foaming and aeration , good functional ingredients, delicate taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031] Example 1

[0032] A method for preparing mochi bread with good freeze-thaw stability includes the following steps:

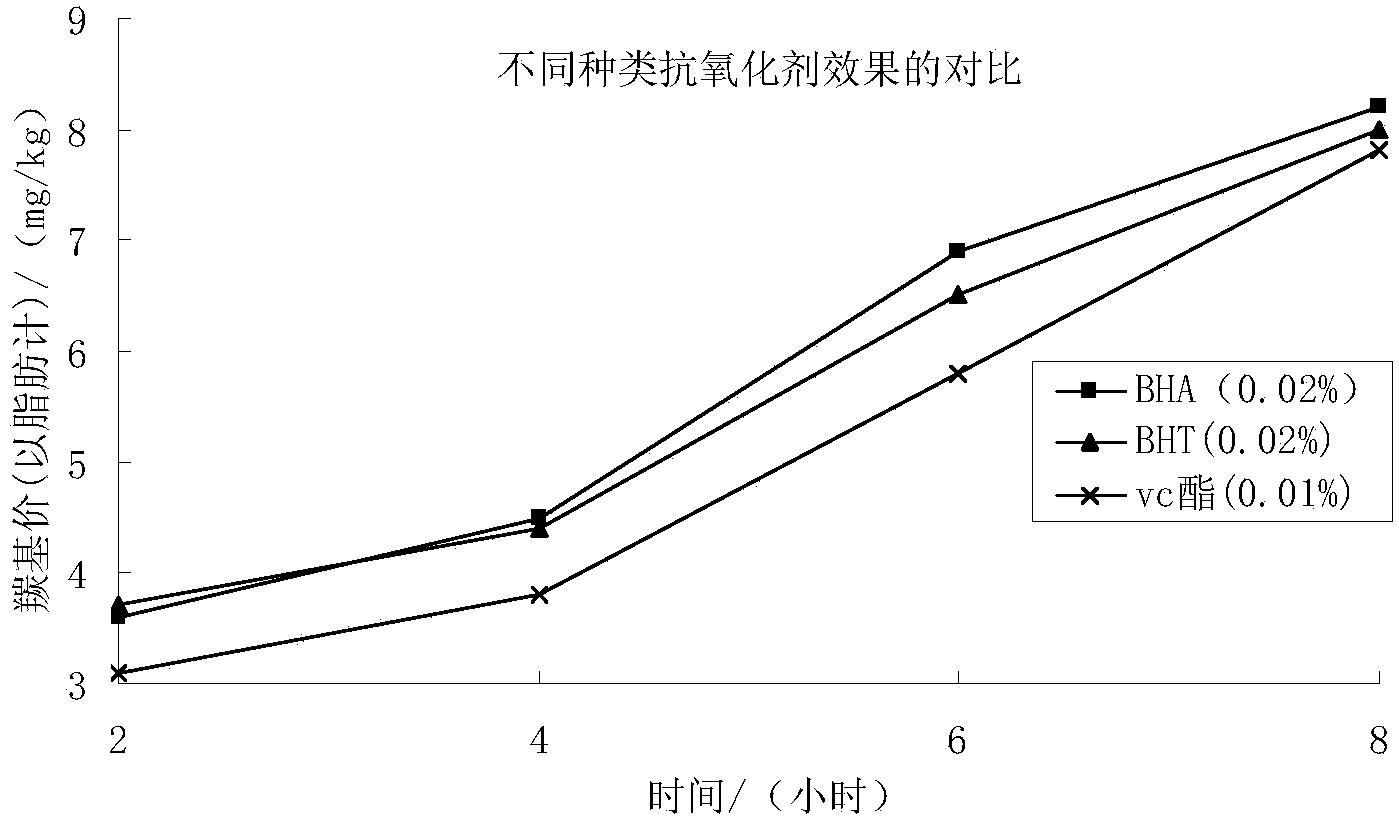

[0033] (1) Combine low-gluten wheat flour, glutinous rice flour, whey powder, modified acetate starch, white sugar, maltodextrin, gluten, potassium polymetaphosphate, salt, gluconic acid-δ-lactone and ascorbyl palmitate Mix and stir evenly to obtain mochi bread premix flour; among them, in weight percentage: 25% low-gluten wheat flour, 15% glutinous rice flour, 2% whey powder, 40% modified acetate starch, 15% white sugar, and malt 1% dextrin, 1% gluten, 0.5% potassium polymetaphosphate, 0.5% salt, 0.1% gluconate-δ-lactone, and 0.01% ascorbyl palmitate;

[0034] (2) Add 100g of water, 20g of eggs, 140g of mochi bread mix prepared in step (1) and 50g of olive oil into the mixing tank, mix at slow speed and stir at medium speed for 1 minute to obtain mochi bread slurry ;

[0035] (3) Use a piping bag to make the mochi bread slurry prepared in step (2) into the de...

Example Embodiment

[0037] Example 2

[0038] A method for preparing mochi bread with good freeze-thaw stability includes the following steps:

[0039] (1) Combine low-gluten wheat flour, glutinous rice flour, whey powder, modified acetate starch, white sugar, maltodextrin, gluten, potassium polymetaphosphate, salt, gluconic acid-δ-lactone and ascorbyl palmitate Mix and stir evenly to obtain mochi bread ready-mixed flour; among them, by weight percentage: 20% low-gluten wheat flour, 15% glutinous rice flour, 3% whey powder, 40% acetate modified starch, 15% white sugar, Maltodextrin 3%, gluten 2%, potassium polymetaphosphate 1%, salt 1%, gluconate-delta-lactone 0.1% and ascorbyl palmitate 0.02%;

[0040] (2) Add 90g of water, 40g of eggs, 140g of mochi bread mix prepared in step (1) and 50g of rapeseed oil into the mixing tank, mix at a slow speed and mix at a medium speed for 1 minute to obtain mochi bread slurry material;

[0041] (3) Use a piping bag to make the mochi bread slurry prepared in step (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com