Water-based superhydrophobic coating and preparation method thereof

A super-hydrophobic coating, water-based technology, applied in coatings and other directions, can solve the problems of large amount of organic solvents, dependence, complex process, etc., to achieve the effect of optimizing coating performance, increasing coating thickness, and simple preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

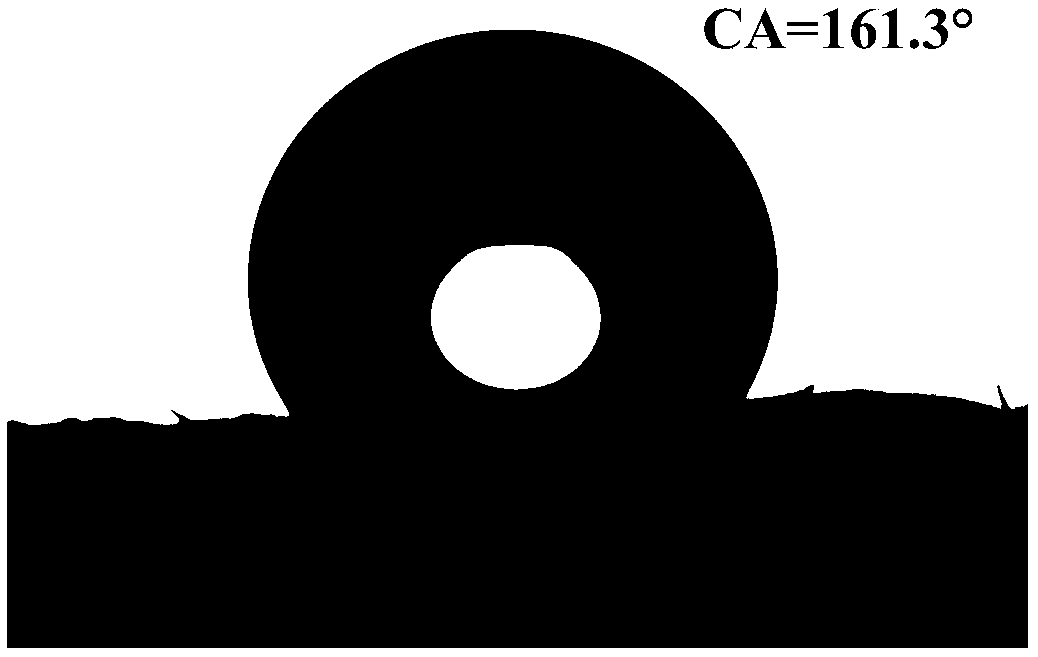

[0039] Take the hydrophobic silicone resin prepolymer (Sylgard 184A, Dow Corning) and its curing agent (Sylgard184B, Dow Corning) and dissolve it in tetrahydrofuran, a good solvent, add fumed silica (particle size 7nm-13nm) after completely dissolving, Use a high-speed disperser to disperse at a speed of 5000r / min for 5 minutes to obtain a uniformly dispersed suspension. The resulting suspension was placed in a container, which was immersed in an ultrasonic water bath. Set the ultrasonic frequency to 25KHz, add distilled water drop by drop in a water bath at 30°C, and finish dropping within 30 minutes to obtain a uniformly dispersed emulsion. Wherein, the raw materials of the super-hydrophobic water-based coatings account for the total raw material mass percentages: 1% hydrophobic silicone resin, 0.3% curing agent, 30% tetrahydrofuran, 0.2% fumed silica, and the balance of water.

[0040] Immerse the cleaned nylon fabric in the dispersed emulsion, soak it at a system temperat...

Embodiment 2

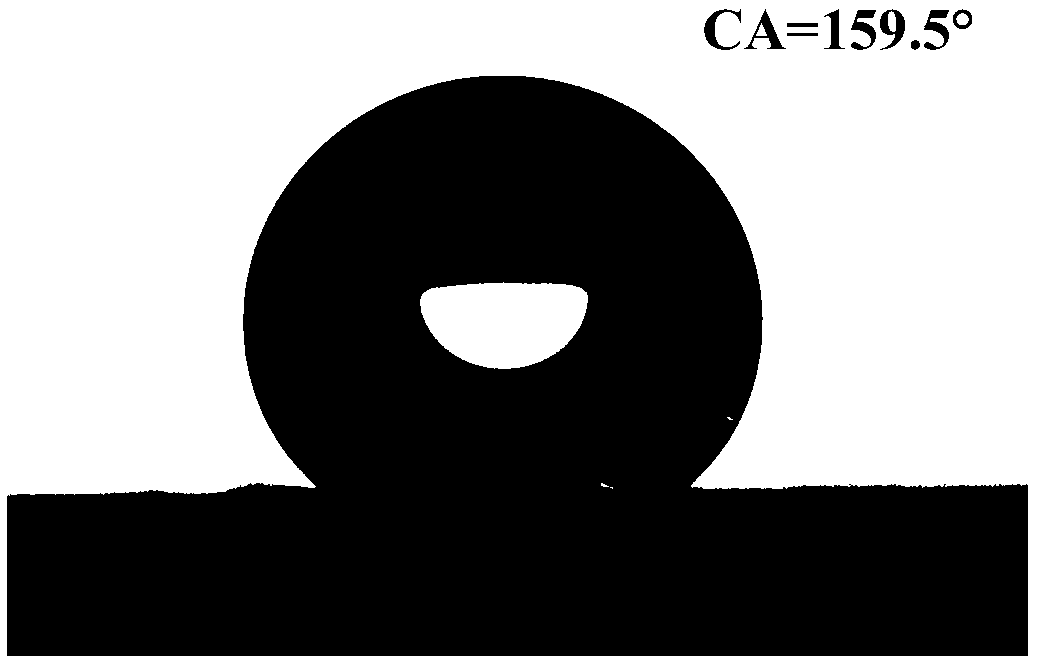

[0042] Take the hydrophobic silicone resin prepolymer (Sylgard 184A, Dow Corning) and its curing agent (Sylgard184B, Dow Corning) and dissolve it in tetrahydrofuran, a good solvent, and add fluorine-modified nano-silica (particle size 20nm- 30nm), using a high-speed disperser to disperse at a speed of 7000r / min for 5min to obtain a uniformly dispersed suspension. The resulting suspension was placed in a container, which was immersed in an ultrasonic water bath. Set the ultrasonic frequency to 25KHz, add distilled water drop by drop in a water bath at 30°C, and finish dropping within 50 minutes to obtain a uniformly dispersed emulsion. Wherein, the raw materials of the super-hydrophobic water-based coatings account for the total raw material mass percentages: 6% hydrophobic silicone resin, 0.5% curing agent, 50% tetrahydrofuran, 6% fluorine-modified silicon dioxide, and the balance of water.

[0043] Immerse the cleaned nylon fabric in the dispersed emulsion, soak it at a syst...

Embodiment 3

[0045] Get hydrophobic fluorocarbon resin polyvinylidene fluoride (molecular weight 100000) and polymethyl methacrylate (molecular weight 30000) and dissolve in its good solvent tetrahydrofuran, add alkyl modified nano-silica (particle size 50nm -70nm), using a high-speed disperser to disperse for 10min at a speed of 4000r / min to obtain a uniformly dispersed suspension. The resulting suspension was placed in a container, which was immersed in an ultrasonic water bath. Set the ultrasonic frequency to 30KHz, add distilled water drop by drop in a water bath at 30°C, and finish dropping within 60 minutes to obtain a uniformly dispersed emulsion. Among them, the raw materials of super-hydrophobic water-based coatings account for the total raw material mass percentages: 10% hydrophobic fluorocarbon resin, 0.8% polymethyl methacrylate adhesive resin, 60% tetrahydrofuran, alkyl modified dioxide Silicon 3%, the balance water.

[0046] Select an area of the exterior wall of the buil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com