Efficient degreaser and preparation and application methods thereof

A degreaser and high-efficiency technology, which is applied in the field of high-efficiency degreaser and preparation, can solve the problems of the surfactant scavenger with many foams, difficult handling, and increasing the difficulty of cleaning the grit chamber, so as to achieve a significant degreasing effect and reduce the interface. The effect of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

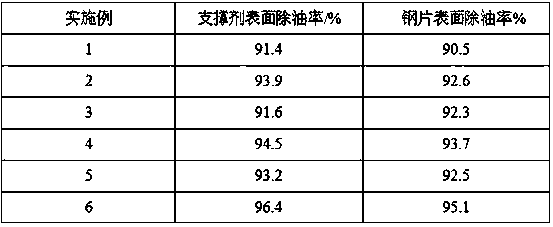

Examples

Embodiment 1

[0027] This embodiment provides a high-efficiency degreasing agent, which is composed of the following substances in weight percentage: 20.0% surfactant, 10.0% solvent, 3.0% alkali, 2.0% inorganic salt, and the rest is water.

[0028] Preparation process: Step 1) Fully mix the formulated amount of alkali and inorganic salt in water with part of the water, and the mixing temperature is 50°C to obtain the mixture A;

[0029] Step 2) Add the formulated amount of surfactant and solvent into the mixture A, stir the reaction time for 5 hours, and obtain the mixture B;

[0030] Step 3) Add the remaining amount of water to the mixture B and stir to obtain a high-efficiency degreasing agent.

[0031] In this example, the surfactant is a mixture of sodium dodecylbenzenesulfonate and nonylphenol polyoxyethylene ether (TX-10), with a mass ratio of 1:1; the solvent is ethanol and ethylene glycol monobutyl A mixture of ethers, the mass ratio is 1:1.

[0032] Principle of the present inven...

Embodiment 2

[0035] This embodiment provides a high-efficiency degreasing agent, which is composed of the following substances in weight percentage: 25.0% surfactant, 15.0% solvent, 5.0% alkali, 5.0% inorganic salt, and the rest is water.

[0036] Preparation process: Step 1) Fully mix the formulated amount of alkali and inorganic salt in water with part of the water, and the mixing temperature is 55°C to obtain the mixture A;

[0037] Step 2) Add the formulated amount of surfactant and solvent into mixture A, stir for 6 hours to obtain mixture B;

[0038] Step 3) Add the remaining amount of water to the mixture B and stir to obtain a high-efficiency degreasing agent.

[0039] In this example, the surfactant is a mixture of sodium dodecylbenzenesulfonate and nonylphenol polyoxyethylene ether (TX-10), with a mass ratio of 1:2; the solvent is ethanol and ethylene glycol monobutyl A mixture of ethers, the mass ratio is 1:3.

Embodiment 3

[0041] This embodiment provides a high-efficiency degreasing agent, which is composed of the following substances in weight percentage: 20.0% surfactant, 10.0% solvent, 3.0% alkali, 2.0% inorganic salt, and the rest is water.

[0042] Preparation process: Step 1) Fully mix the formulated amount of alkali and inorganic salt in water with part of the water, and the mixing temperature is 55°C to obtain the mixture A;

[0043] Step 2) Add the formulated amount of surfactant and solvent into mixture A, stir for 6 hours to obtain mixture B;

[0044] Step 3) Add the remaining amount of water to the mixture B and stir to obtain a high-efficiency degreasing agent.

[0045] In this example, the surfactant is a mixture of cis-9-octadecenoic acid and nonylphenol polyoxyethylene ether (TX-10), with a mass ratio of 1:1; the solvent is isopropanol and ethylene glycol The mixture of alcohol monobutyl ether, the mass ratio is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com