Composite coal-dressing flotation reagent and preparation method thereof

A flotation reagent and coal preparation technology, applied in flotation, solid separation and other directions, can solve the problems of weak flotation performance, cumbersome operation procedures, large dosage of reagents, etc., to overcome poor stability, simplify technological process, The effect of reducing the dosage of the drug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

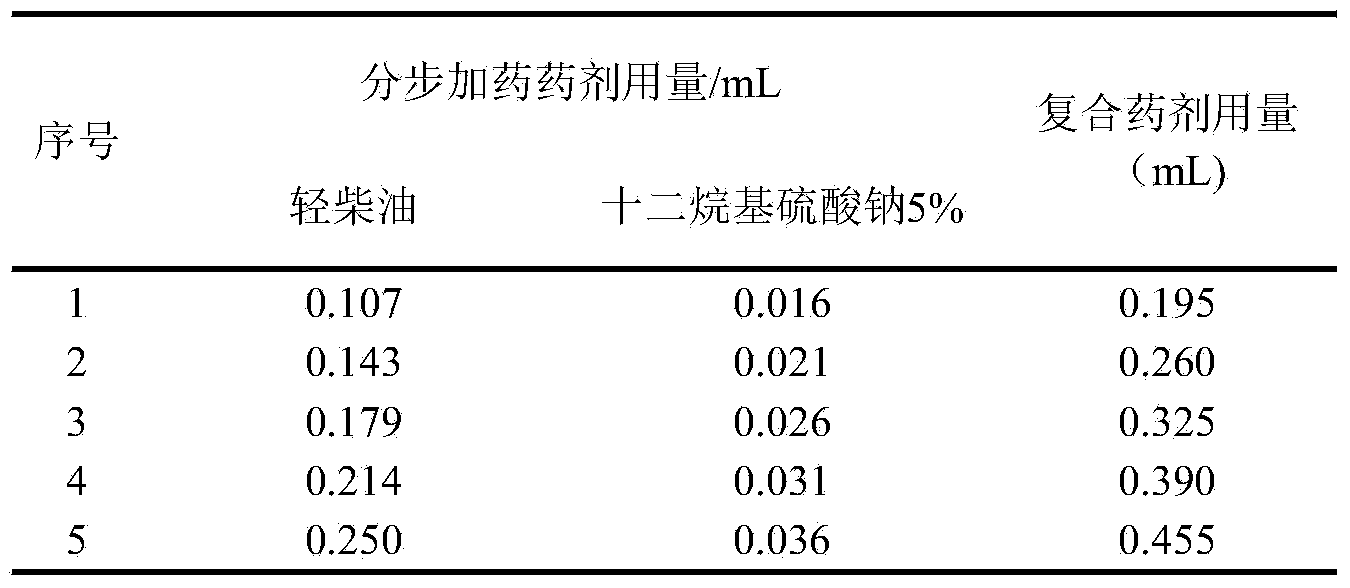

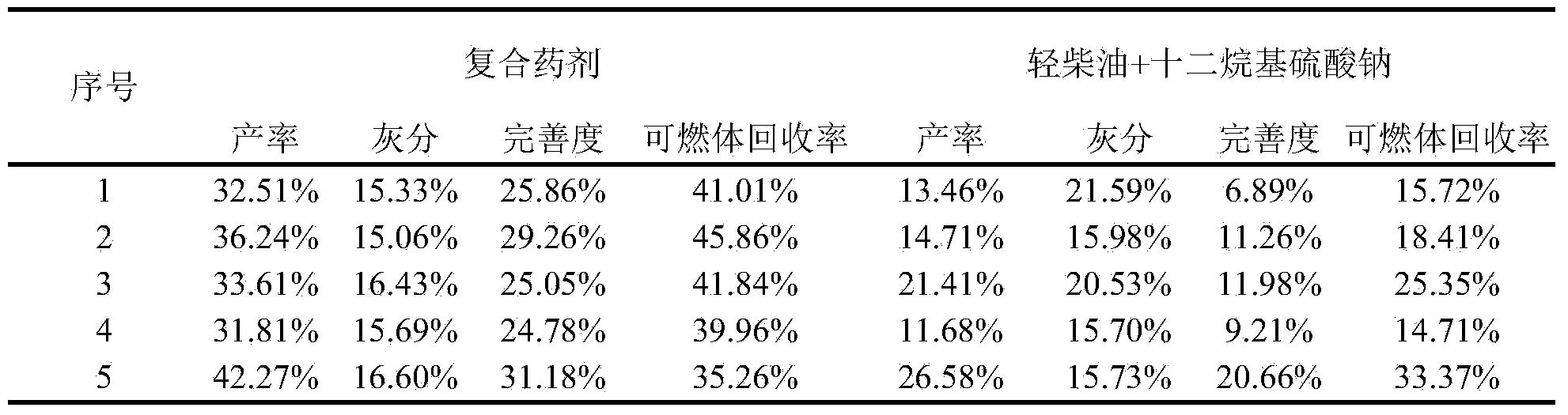

Embodiment 1

[0018] The composite coal preparation flotation agent is composed of 50% light diesel oil, 0.5% sodium lauryl sulfate, 0.4% alkyl glycoside, 3% alkylphenol polyoxyethylene ether and 46% water by mass percentage. Sodium lauryl sulfate, alkyl glucoside, and alkylphenol polyoxyethylene ether were configured into aqueous solutions with mass fractions of 5%, 10%, and 20%, respectively, and then 25mL of light diesel oil was added to the reaction vessel, and magnetically Add 5mL sodium lauryl sulfate, 2.5mL alkyl glucoside and 7.5mL alkylphenol polyoxyethylene ether under the condition of stirring. After stirring for 5 minutes, use a high-speed cutting emulsifier to emulsify at a working speed of 3000r / min for 10 minutes to obtain Milky white water-soluble compound coal preparation flotation agent.

[0019] The composite coal preparation flotation agent prepared in this example was left to stand naturally at room temperature for 24 hours, and was shaken and shaken in due course to ob...

Embodiment 2

[0022] The composite coal preparation flotation agent is composed of 65% light diesel oil, 0.5% sodium lauryl sulfate, 0.6% alkyl glycoside, 4% alkylphenol polyoxyethylene ether and 40% water by mass percentage. Sodium lauryl sulfate, alkyl glucoside, and alkylphenol polyoxyethylene ether were respectively configured into aqueous solutions with a mass fraction of 5%, 10% and 20%, and then 32.5mL of light diesel oil was added to the reaction vessel, and heated at room temperature Under the condition of magnetic stirring, add 5mL sodium lauryl sulfate, 3mL alkyl glucoside and 10mL alkylphenol polyoxyethylene ether, after stirring for 5min, use a high-speed cutting emulsifier to emulsify at a working speed of 2000r / min for 20min to obtain milky white Water-soluble composite coal preparation flotation agent.

[0023] The composite coal preparation flotation agent prepared in this example has good stability at room temperature. The yield of clean coal in flotation experiments is 34...

Embodiment 3

[0025] The composite coal preparation flotation agent consists of 55% light diesel oil, 0.4% sodium lauryl sulfate, 0.5% alkyl glycoside, 4% alkylphenol polyoxyethylene ether and 40.1% water by mass percentage. Sodium lauryl sulfate, alkyl glucoside, and alkylphenol polyoxyethylene ether were respectively configured into aqueous solutions with a mass fraction of 5%, 10% and 20%, and then 27.5mL of light diesel oil was added to the reaction vessel, and heated at room temperature Under the condition of magnetic stirring, add 4mL sodium lauryl sulfate, 2.5mL alkyl glycoside and 10mL alkylphenol polyoxyethylene ether, after stirring for 5min, use a high-speed cutting emulsifier to emulsify at a working speed of 2500r / min for 15min to obtain Milky white water-soluble compound coal preparation flotation agent.

[0026] The composite coal preparation flotation agent prepared in this example has good stability at room temperature. The yield of clean coal in flotation experiments is 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com