Range hood with self-cleaning function

A range hood and self-cleaning technology, which is applied in the direction of removing oil fumes, household appliances, household heating, etc., can solve the problems of short contact time, poor cleaning effect, and increased cleaning cost, so as to prolong the contact time and improve the cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

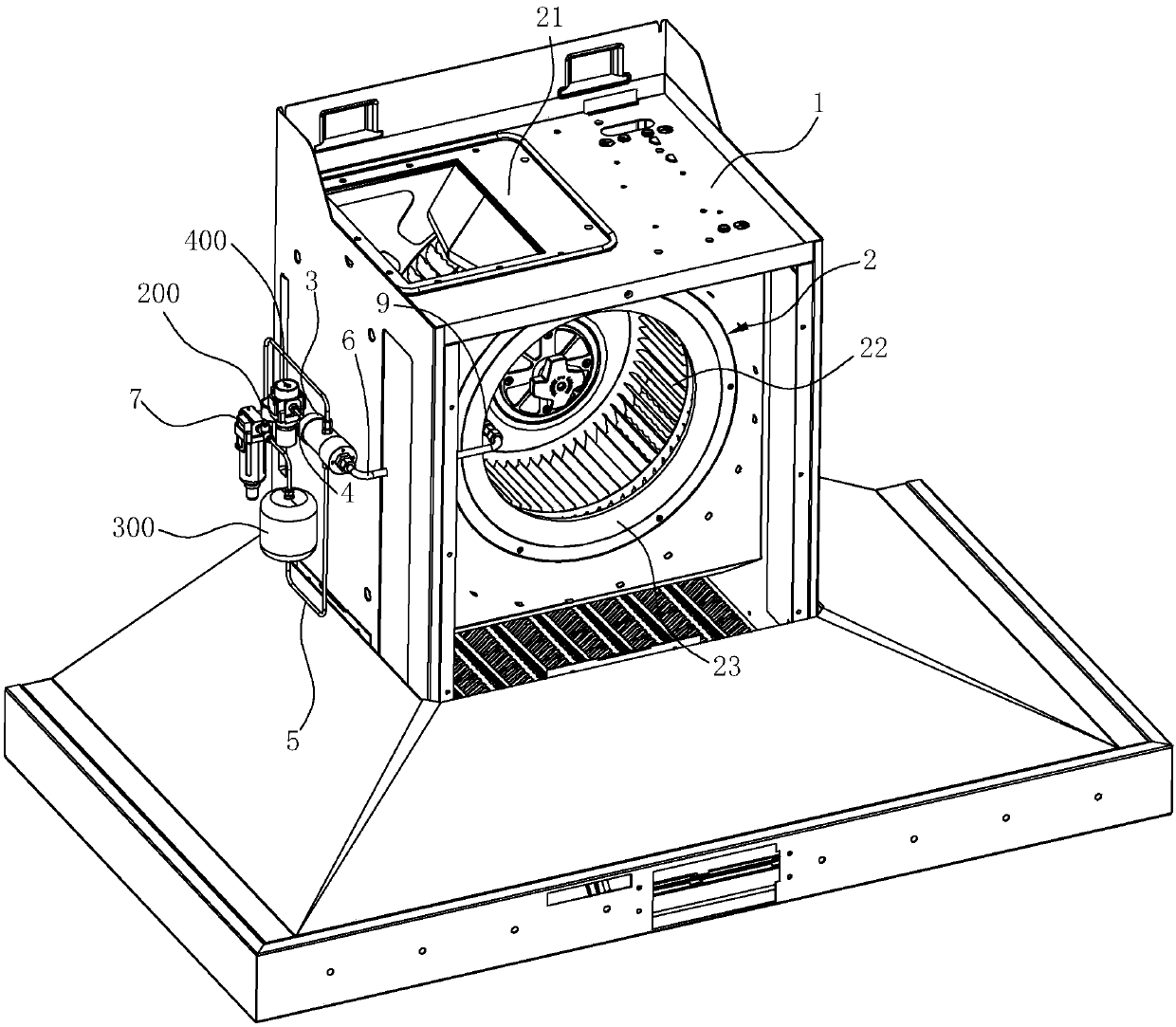

[0029] Such as Figure 1~5 As shown, the range hood with self-cleaning function of this embodiment includes a casing 1, a fan 2 and a cleaning assembly, the fan 2 is arranged in the casing 1, and the fan 2 of this embodiment is a centrifugal fan with a volute 21 and a The impeller 22 in the volute 21 and the air inlet 23 of the fan 2 are arranged forward. The cleaning component is arranged in the casing 1 and can spray cleaning medium into the fan 2 .

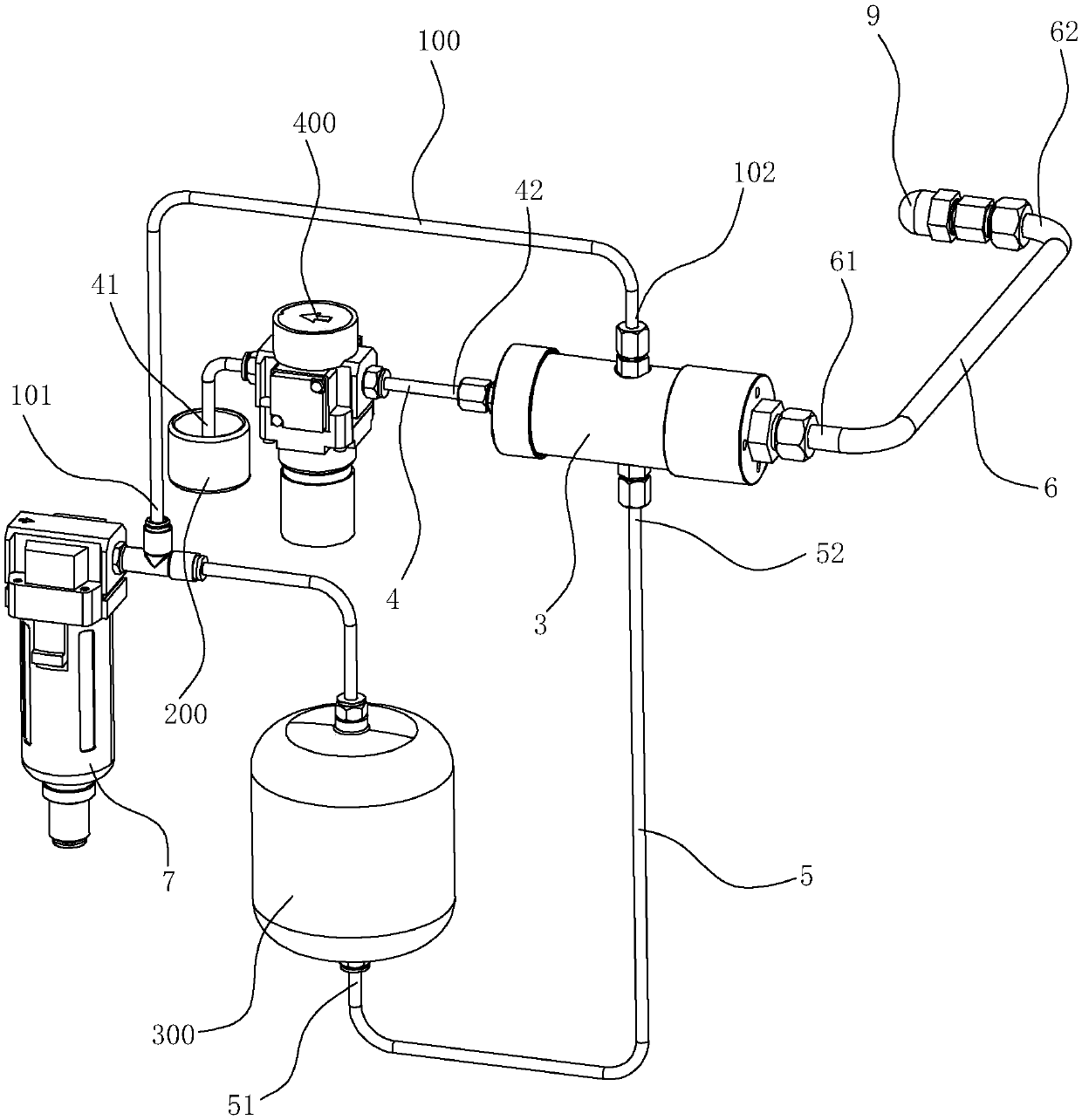

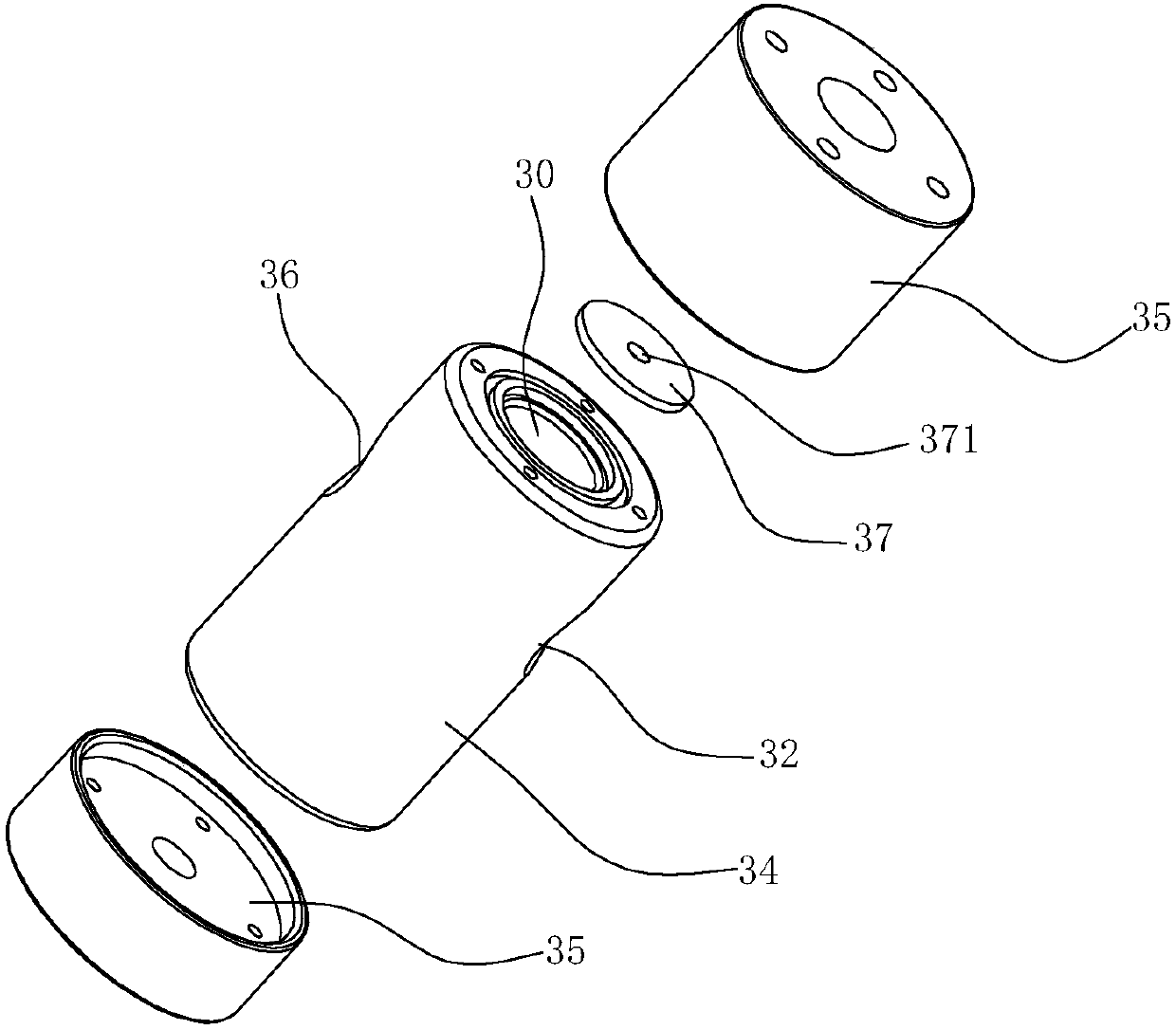

[0030] In this embodiment, the cleaning component is arranged on the outer wall of the casing 1, so as to add water and detergent and the like. The cleaning assembly includes a foaming seat 3, a first fluid guide tube 4, a driver 400, a second fluid guide tube 5, a third fluid guide tube 6, an air compression pump 7, an air guide tube 100, a water storage tank 200 and a detergent storage tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com