High-fluidity and high-rigidity alloy composite material and preparation method thereof

A composite material and high fluidity technology, which is applied in the field of high rigidity alloy composite material and its preparation, and high fluidity, can solve the problems of fluidity, dispersion and poor rigidity, achieve high fluidity, excellent impact toughness, improve The effect of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

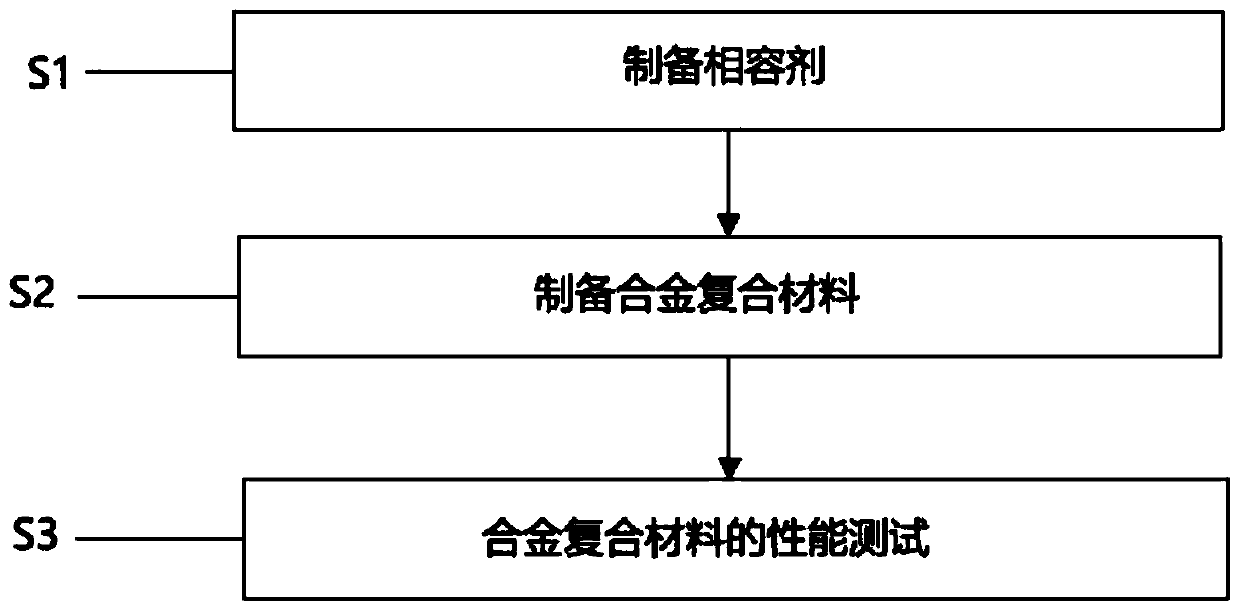

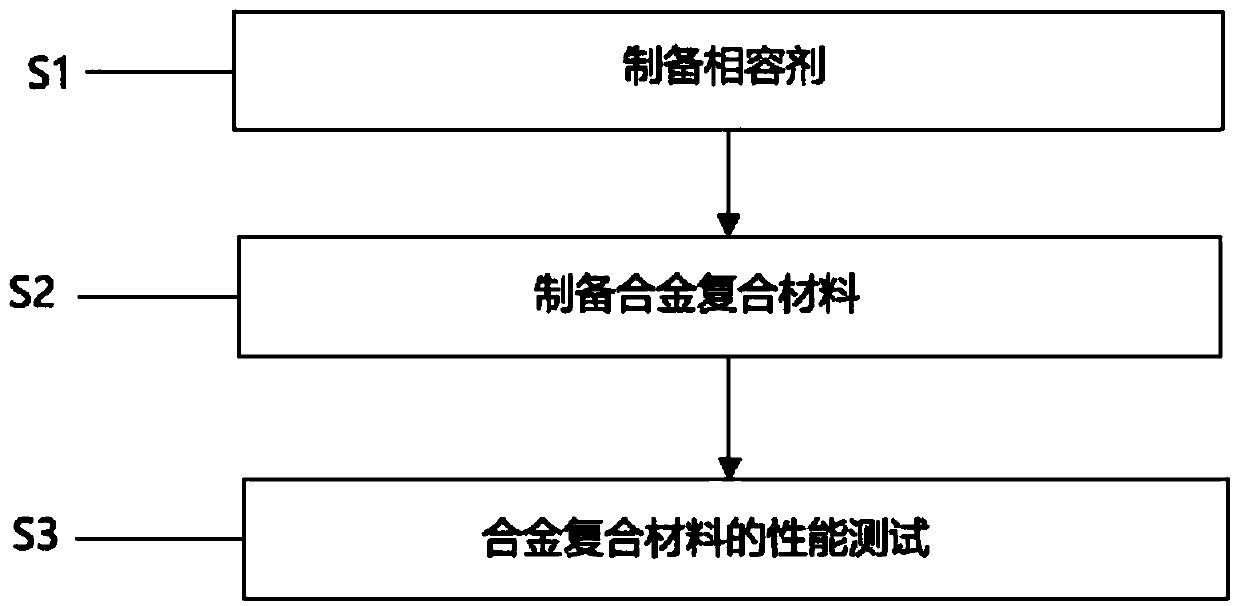

[0038] Such as figure 1 As shown, a high fluidity, high rigidity alloy composite preparation method,

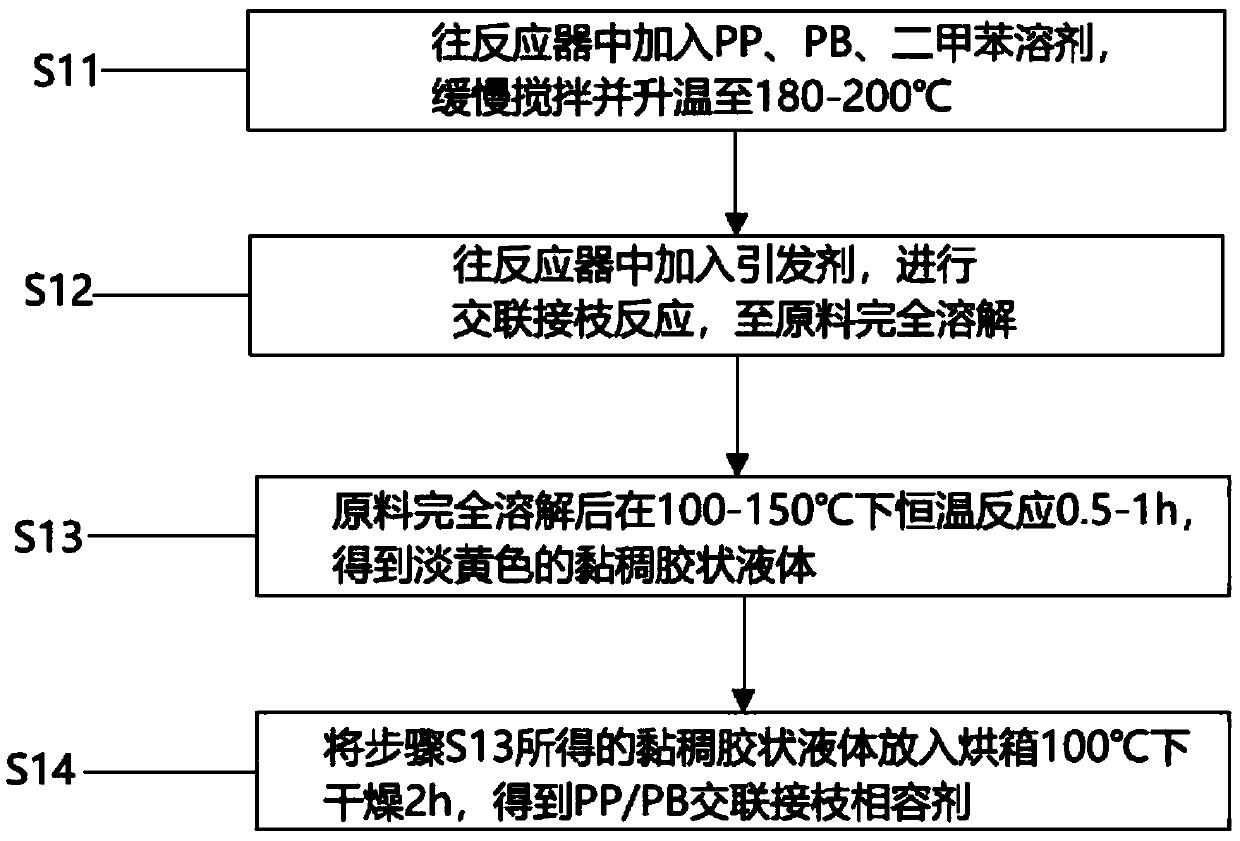

[0039] S1: Preparation of compatibilizer,

[0040] S11: Add PP, PB, and xylene solvents into the reactor, stir slowly and raise the temperature to 180-200°C;

[0041] PP is homopolypropylene, PB is n-butylene, both materials are general-purpose grades, xylene is analytically pure, and the mass ratio of PP:PB:xylene is 6:4:20; the stirring speed is 150 ~200r / min;

[0042] S12: adding an initiator into the reactor to carry out cross-linking and grafting reaction until the raw materials are completely dissolved;

[0043] 1h, 2h, and 3h after the start of the reaction, add 0.5% to 2.5% initiator (benzoyl peroxide / dicumyl peroxide) to carry out cross-linking and grafting reaction;

[0044] S13: After the raw materials are completely dissolved, react at a constant temperature of 100-150°C for 0.5-1h to obtain a light yellow viscous colloidal liquid;

[0045] After the pellets ...

Embodiment 2

[0059] The difference between this example and Example 1 is that the alloy composite material is prepared in S2: 80.0% of PP resin, 7.0% of PB resin, 0.0% of compatibilizer, 2.0% of toughening agent, 10.0% of inorganic powder, and 0.5% of auxiliary agent are added to Mix in a high-speed mixer with a rotation speed of 500r / min for 3 minutes, and then granulate through a twin-screw extruder, that is, after melting and plasticizing, the granules are extruded from the die head, and the extrusion processing temperature is 180 ° C, cooled, Dry and pelletize to obtain alloy composite material.

[0060] The obtained alloy composite material is tested according to the method of Example 1, and the tensile strength obtained is 23.2MPa; the bending strength is 29.1MPa; the bending modulus is 2210.1MPa; the notched impact is 7.6KJ / m 2 ; Melt index 25.6g / 10min.

Embodiment 3

[0062] The difference between this example and Example 1 is that the alloy composite material is prepared in S2: 80.0% of PP resin, 7.0% of PB resin, 0.5% of compatibilizer, 2.0% of toughening agent, 10.0% of inorganic powder, and 0.5% of auxiliary agent are added to Mix in a high-speed mixer with a rotation speed of 500r / min for 3 minutes, and then granulate through a twin-screw extruder, that is, after melting and plasticizing, the granules are extruded from the die head, and the extrusion processing temperature is 180 ° C, cooled, Dry and pelletize to obtain alloy composite material.

[0063] The obtained alloy composite material is tested according to the method of Example 1, and the tensile strength obtained is 30.1MPa; the bending strength is 38.2MPa; the bending modulus is 2530.1MPa; the notched impact is 10.3KJ / m 2 ; Melt index 30.5g / 10min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com