Preparation method of anorthite-based porous lightweight refractory material

A light-weight refractory material, anorthite technology, applied in ceramic products, applications, household appliances, etc., can solve the problems of increasing content, too fast increase of slurry viscosity, roasting cracking, etc., to increase strength and refractoriness, distribution Uniform, stable effect with the presence of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

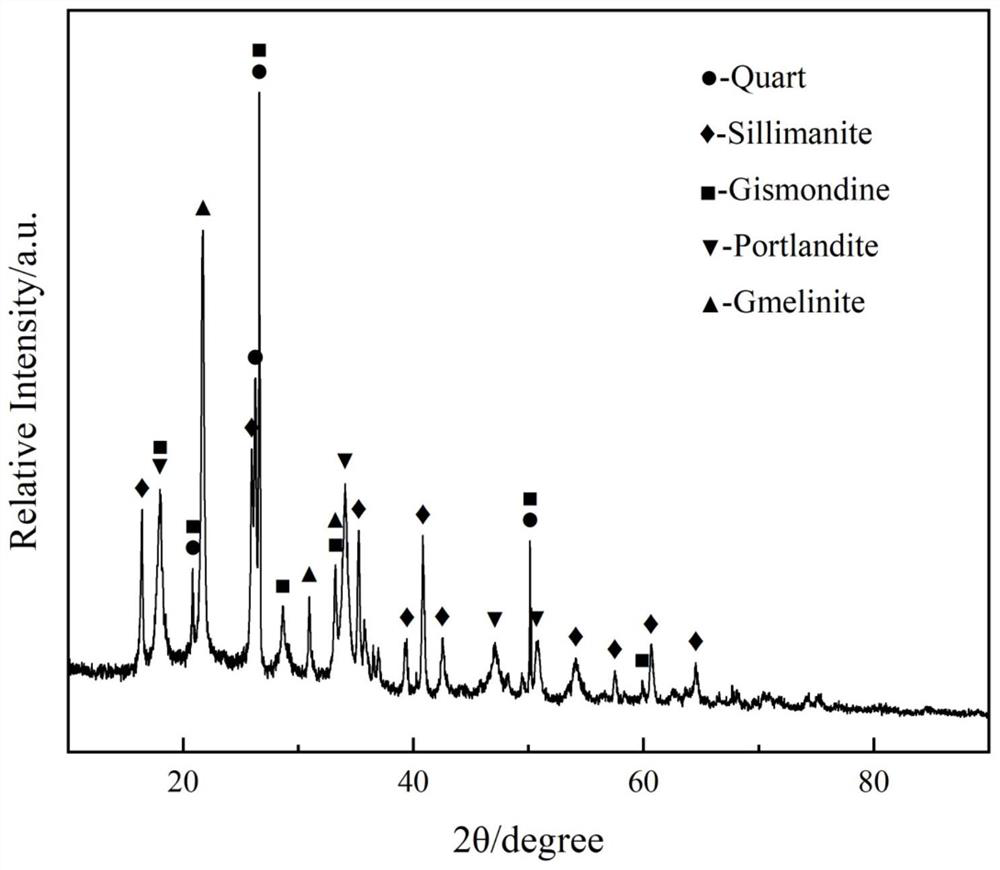

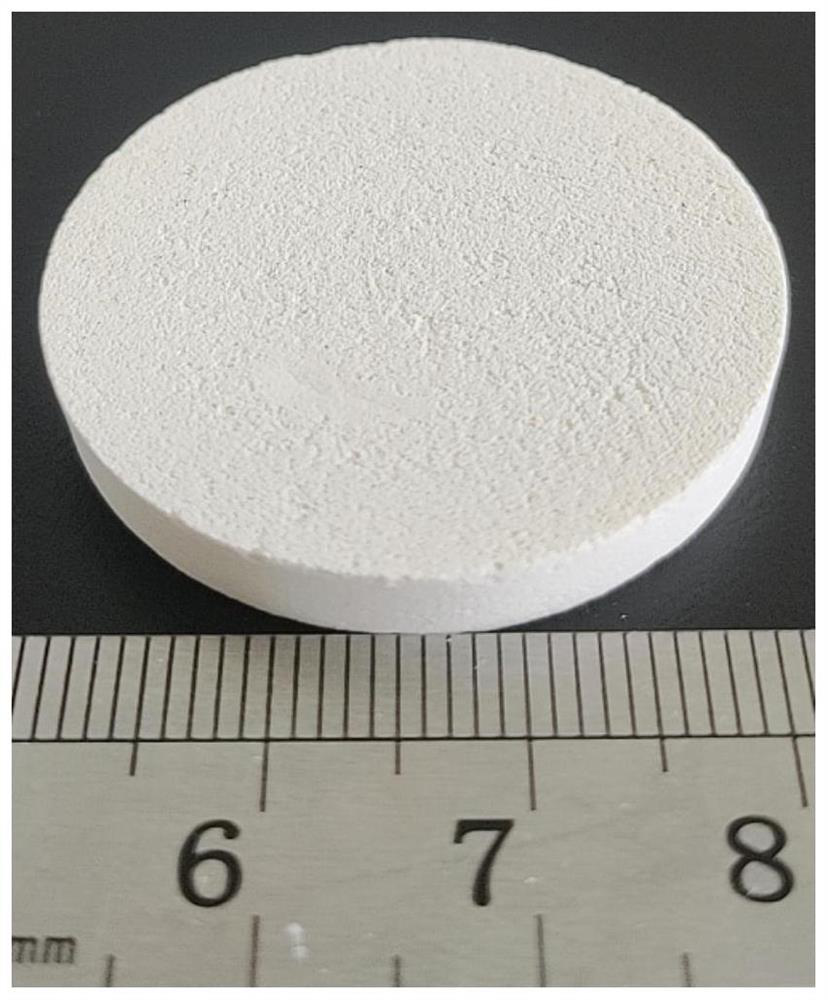

Image

Examples

preparation example Construction

[0036] A preparation method of anorthite-based porous lightweight refractory material, comprising the steps of:

[0037] 1) Dissolve the foam stabilizer polyvinyl alcohol in the aqueous solution to obtain the PVA aqueous solution; to dissolve the PVA, it needs to be stirred and swelled in cold water first, and then the water temperature is gradually raised to 85-95°C and then kept for 20-40 minutes;

[0038]2) Add tetramethylammonium hydroxide aqueous solution to the obtained PVA aqueous solution, and mix uniformly to obtain an alkaline excitation solution; the mass fraction of tetramethylammonium hydroxide in the alkaline excitation solution is 25wt.%, tetramethylhydrogen The mass ratio of ammonium oxide, raw material powder and offal water of the system is 0.08~0.1:100;

[0039] 3) Add metakaolin powder, calcium oxide powder, and silicon dioxide powder into the obtained alkaline excitation solution, and stir evenly to obtain calcium-aluminosilicate-based geopolymer slurry; m...

Embodiment 1

[0044] Prepare the anorthite-based porous lightweight refractory according to the following steps:

[0045] 1) Preparation of PVA aqueous solution A: Pour 1 wt.% PVA powder relative to the total distilled water content of the experiment into distilled water at room temperature, and while maintaining magnetic stirring, slowly heat the aqueous solution to 90° C. and keep it warm for 30 minutes to obtain PVA aqueous solution A;

[0046] 2) Preparation of alkaline excitation solution B: add tetramethylammonium hydroxide aqueous solution with a mass fraction of 25wt.% to solution A, and stir for 10 minutes under magnetic stirring at a rotational speed of 1000rpm to obtain a TMAH content of 8.7wt.% relative to the raw material powder Alkaline excitation solution B;

[0047] 3) Preparation of calcium-aluminosilicate-based geopolymer slurry C: Weigh out metakaolin powder, calcium oxide powder and silicon dioxide powder of corresponding quality according to the molar ratio of silicon, ...

Embodiment 2

[0057] Change the mass ratio of total powder to total water in step 3) of Example 1 to 1:1, and the remaining steps and parameters are exactly the same as in Example 1. The porous calcium aluminum silicate-based geopolymer prepared under this condition The bulk density of green body is 0.929g / cm 3 , the compressive strength is 10.86MPa; the volume density of the anorthite-based porous lightweight refractory material prepared under this condition is 0.847g / cm 3 , the porosity is 64%, the compressive strength is 24.33MPa, and the thermal conductivity is 0.1511W / mK.

[0058] Figure 6 It is the OM / SEM figure after the gold plating of the anorthite-based porous lightweight refractory material obtained by the above-mentioned preparation method, from Figure 6 It can be seen that the pore size of the refractory material is uneven and unevenly distributed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com