Graphene modified inorganic potassium silicate coating and preparation method thereof

A technology of graphene modification and potassium silicate, which is applied in the direction of alkali metal silicate coatings, anti-corrosion coatings, coatings, etc., to achieve the effects of improving fluidity, improving corrosion resistance, and improving overall corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

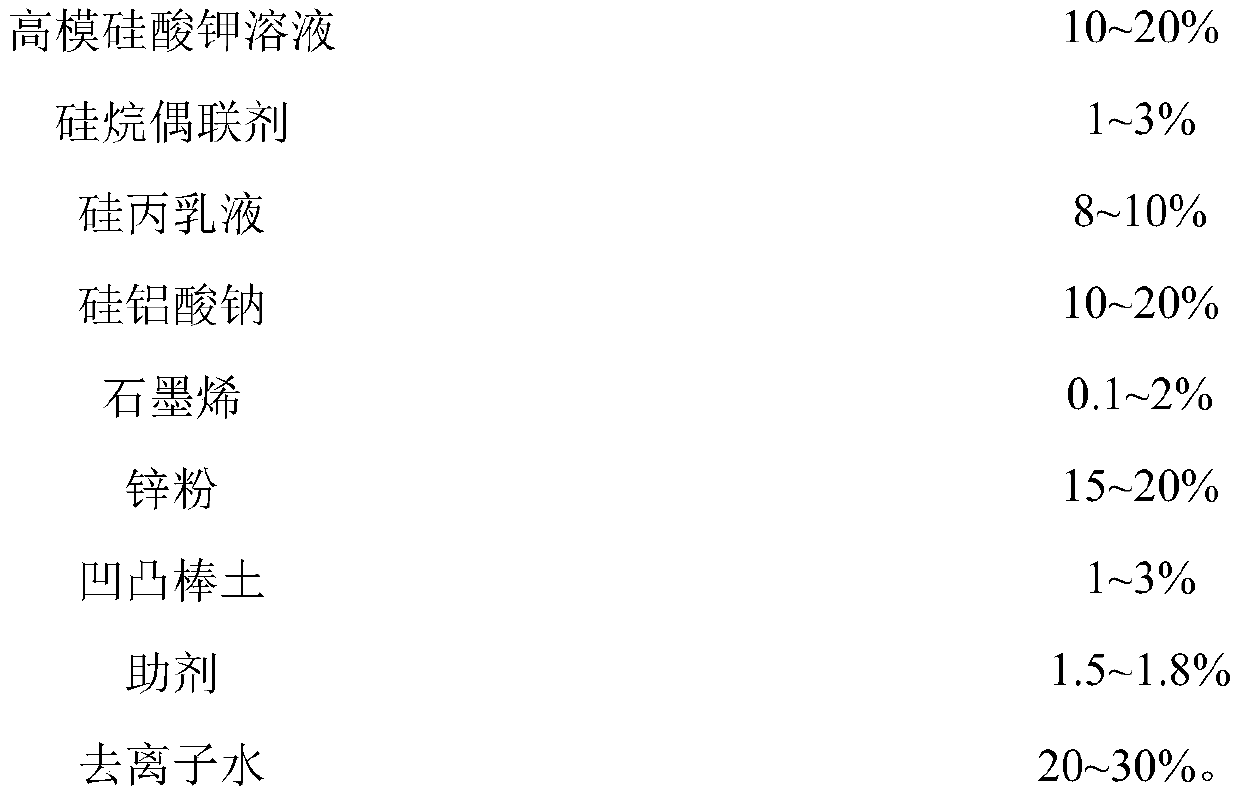

Embodiment 1

[0032] The preparation method of graphene modified inorganic potassium silicate coating comprises the following steps:

[0033] (1) Preparation of high modulus potassium silicate solution

[0034] Weigh the potassium silicate solution with a modulus of 2.5 and the silica sol according to a mass ratio of 1:1, the mass fraction of silicon dioxide in the silica sol is 20%, and place the weighed potassium silicate solution with a modulus of 2.5 in three ports In the flask, stir magnetically at a stirring rate of 500r / min, then slowly drop the silica sol into the three-necked flask, adjust the temperature to 80°C, and add an appropriate amount of water to make the solution appear in a vortex state during the entire stirring process, stirring After 40 minutes, a potassium silicate solution with a modulus of 5.5 was obtained.

[0035] (2) Preparation of silicone acrylic emulsion

[0036] In 100g of distilled water, add 25g of acrylate monomer and 9g of vinyltriethoxysilane, stir an...

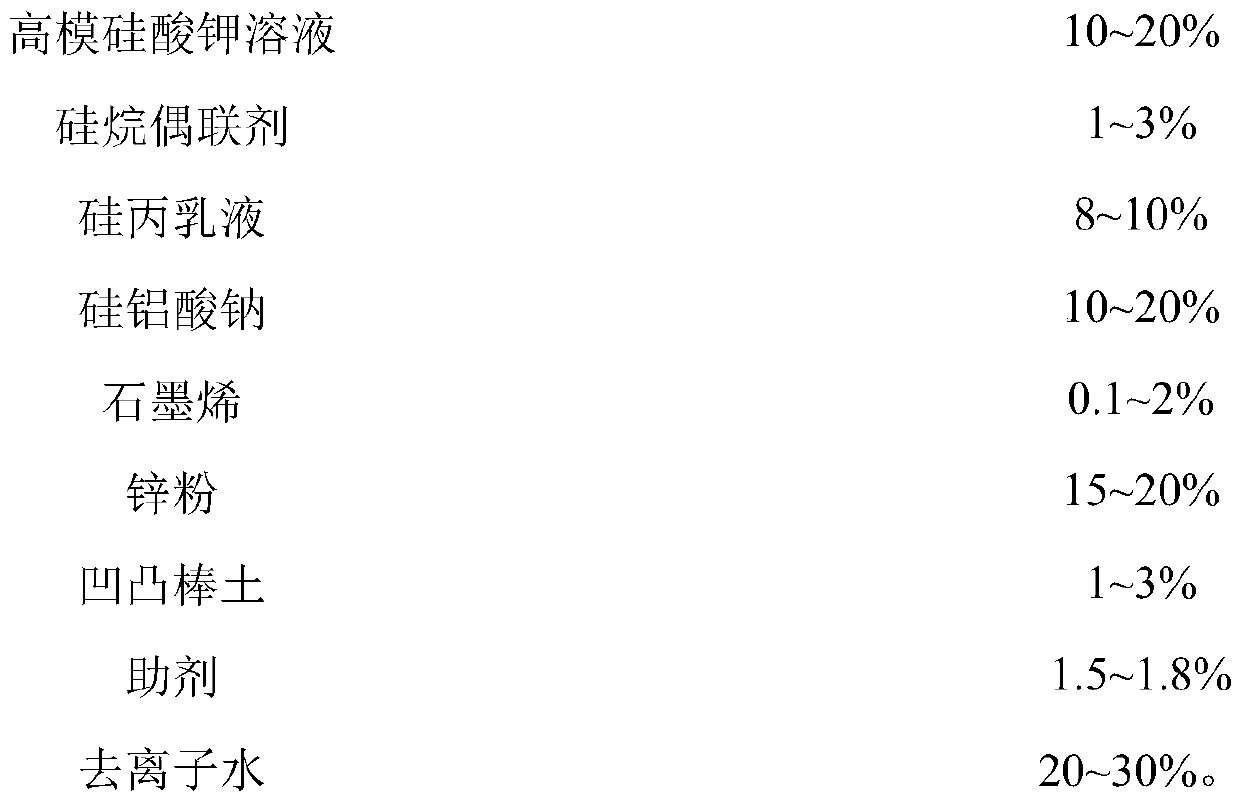

Embodiment 2

[0042] The preparation method of graphene modified inorganic potassium silicate coating comprises the following steps:

[0043] (1) Preparation of high modulus potassium silicate solution

[0044] Weigh the potassium silicate solution with a modulus of 2.5 and the silica sol according to a mass ratio of 1.5:1, the mass fraction of silicon dioxide in the silica sol is 20%, and place the weighed potassium silicate solution with a modulus of 2.5 in three ports In the flask, stir magnetically at a stirring rate of 500r / min, then slowly drop the silica sol into the three-necked flask, adjust the temperature to 85°C, and add an appropriate amount of water to make the solution appear in a vortex state during the entire stirring process, and stir After 40 minutes, a potassium silicate solution with a modulus of 6.5 was obtained.

[0045] (2) Preparation of silicone acrylic emulsion

[0046] In 150g of distilled water, add 30g of acrylate monomer and 10g of vinyltriethoxysilane, stir...

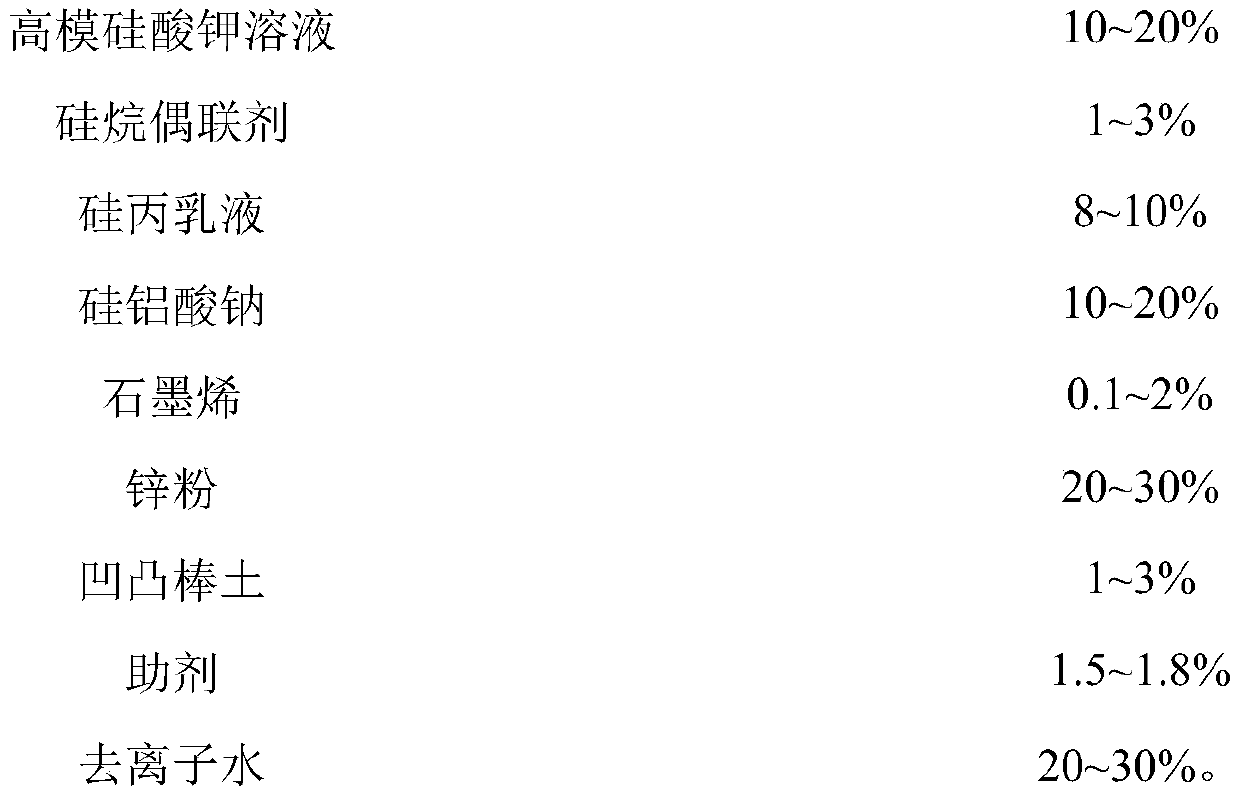

Embodiment 3

[0052] The preparation method of graphene modified inorganic potassium silicate coating comprises the following steps:

[0053] (1) Preparation of high modulus potassium silicate solution

[0054] Weigh the potassium silicate solution with a modulus of 2.5 and the silica sol according to a mass ratio of 1:1, the mass fraction of silicon dioxide in the silica sol is 20%, and place the weighed potassium silicate solution with a modulus of 2.5 in three ports In the flask, stir magnetically at a stirring rate of 500r / min, then slowly drop the silica sol into the three-necked flask, adjust the temperature to 80°C, and add an appropriate amount of water to make the solution appear in a vortex state during the entire stirring process, stirring After 40 minutes, a potassium silicate solution with a modulus of 5.5 was obtained.

[0055] (2) Preparation of silicone acrylic emulsion

[0056] In 100g of distilled water, add 25g of acrylate monomer and 9g of vinyltriethoxysilane, stir an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com