Patents

Literature

120 results about "Sodium silicoaluminate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium Silicoaluminate. Definition. Sodium silicoaluminate is a flow agent that can also be found in products such as salt and powdered milk, as well as latex paints and air filters. We add it to our products as needed to prevent a product from clumping.

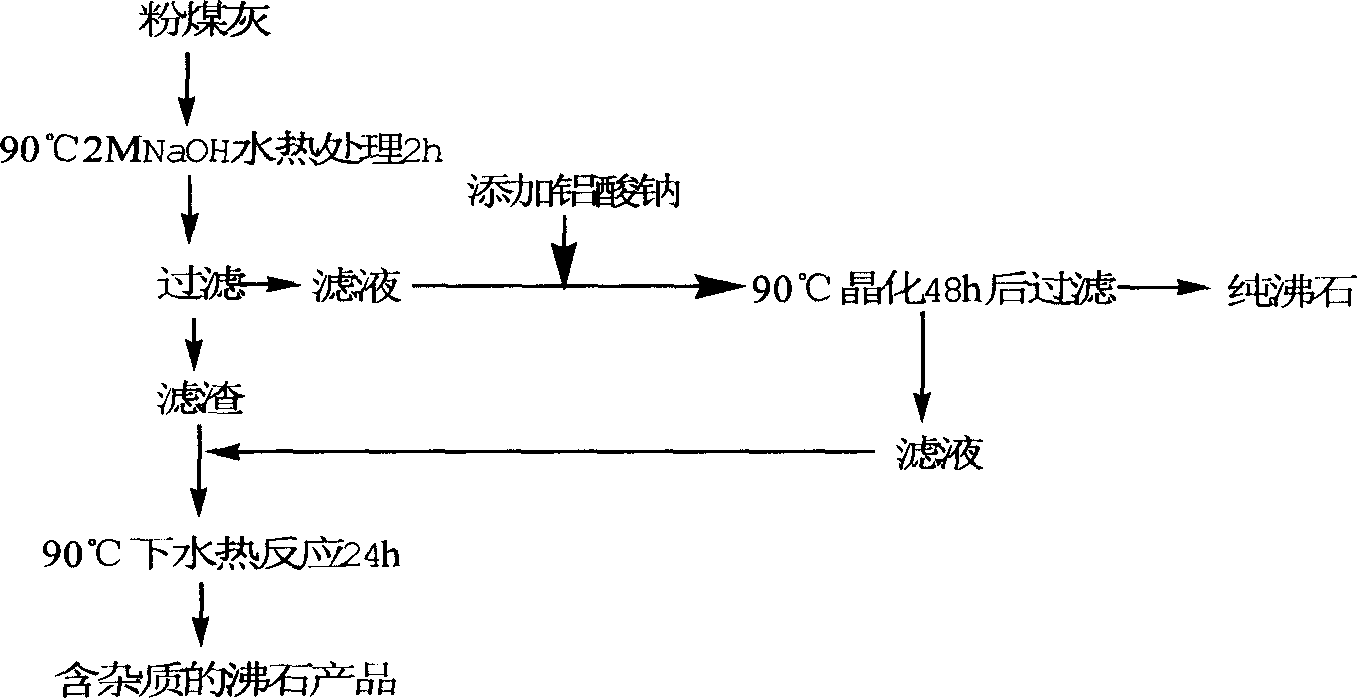

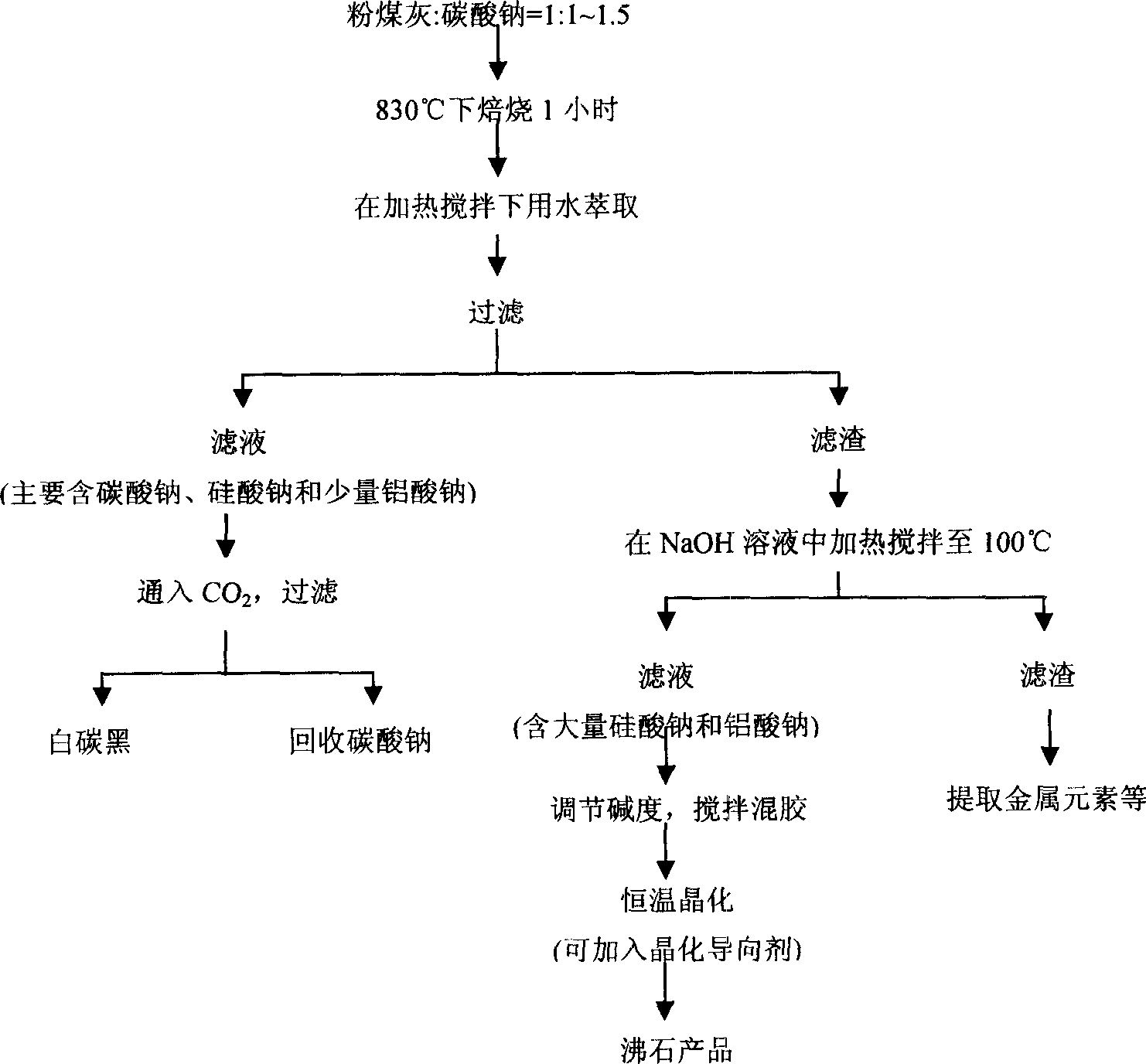

Method for preparing white carbon black and pure zeolite molecular sieve using flyash

InactiveCN1911800AAccelerate emissionsSilicon oxidesCrystalline aluminosilicate zeolitesSolubilityMetallic materials

The process of preparing white carbon black and pure zeolite molecular sieve with fly ash material belongs to the field of inorganic non-metal material preparing technology. The preparation process includes the following steps: roasting the mixture of high silicon fly ash with SiO2 content of 30-65 % and sodium carbonate in the weight ratio of 1 to 1-1.5 at 830 deg.c for 1 hr to obtain roasted product with sodium silicate and sodium aluminosilicate as main components; soaking the roasted product in water in 5 times to leach out sodium silicate with high water solubility, filtering to obtain sodium silicate solution, introducing CO2 to the solution and depositing to obtain white carbon black product; and further leaching desilicated fly ash with alkali solution, heating and stirring to obtain solution of sodium aluminosilicate, which is soluble in strong alkali solution, filtering, regulating pH value and crystallizing to obtain pure zeolite molecular sieve.

Owner:UNIV OF SCI & TECH BEIJING

Method for activating construction waste regenerated micro-powder

InactiveCN102838302AImprove performanceSolid waste managementCement productionSodium silicoaluminateSlag

The invention discloses a method for activating construction waste regenerated micro-powder. The method comprises the following detailed steps of: firstly, subjecting the construction waste regenerated micro-powder with the particle size of less than 0.36mm and lime to an activation treatment, namely, mechanically milling and mixing, and milling at normal temperature till obtaining a powder material with powder fineness less than 0.075mm, wherein the lime doping amount is 5-15% of the total weight of the mixture, and the balance is construction waste regenerated micro-powder; immersing the mechanically activated powder material in a sodium silicoaluminate solution for 18-30h, drying in the air, heating to 900-950 DEG C, holding the temperature for 2-5h, and then naturally cooling to room temperature; mixing and milling the cooled material with slag micro-powder according to the weight ratio of 1:(0.8-1.5) at normal temperature until the specific surface area of the mixed material is more than 450mm<2> / kg. With the adoption of the method, the construction waste regenerated micro-powder with the particle size of less than 0.36mm can be recycled completely, and the activity is high.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Environment-friendly water-based nano anti-aging exterior wall coating

InactiveCN102827521AImprove abrasion resistanceStrong ability to resist wind and sand impactAntifouling/underwater paintsPaints with biocidesSodium aluminateDefoaming Agents

The invention relates to an environment-friendly water-based nano anti-aging exterior wall coating which comprises the components by weight percent: 15-30% of polyacrylic acid emulsion, 1-5% of film-forming additive, 0.1-0.3% of defoaming agent, 0.5-1% of dispersing agent, 0.1-0.5% of wetting agent, 2-5% of flatting agent, 1-6% of emulsifying agent, 15-25% of titanium dioxide, 2-5% of precipitated calcium carbonate, 0.5-3.5% of mica, 1-3% of zinc oxide, 3-7% of sodium silicoaluminate, 1.5-4.5% of talcum powder, 0.5-1% of thickening agent, 0.3-0.5% of mildew preventive, 10-30% of water, 2-5% of environment-friendly additive and 1-3% of water-based nano anti-aging agent. The environment-friendly water-based nano anti-aging exterior wall coating is good in scuff resistance, high in sandstorm impact resistance and even in coating without crack, can be used for blade coating, roller coating and spraying, has the functions of inhibiting bacteria, dispelling peculiar smell and cleaning air, and is remarkable in anti-man-made aging performance.

Owner:WUJIANG WUHUA HARDWARE PROD

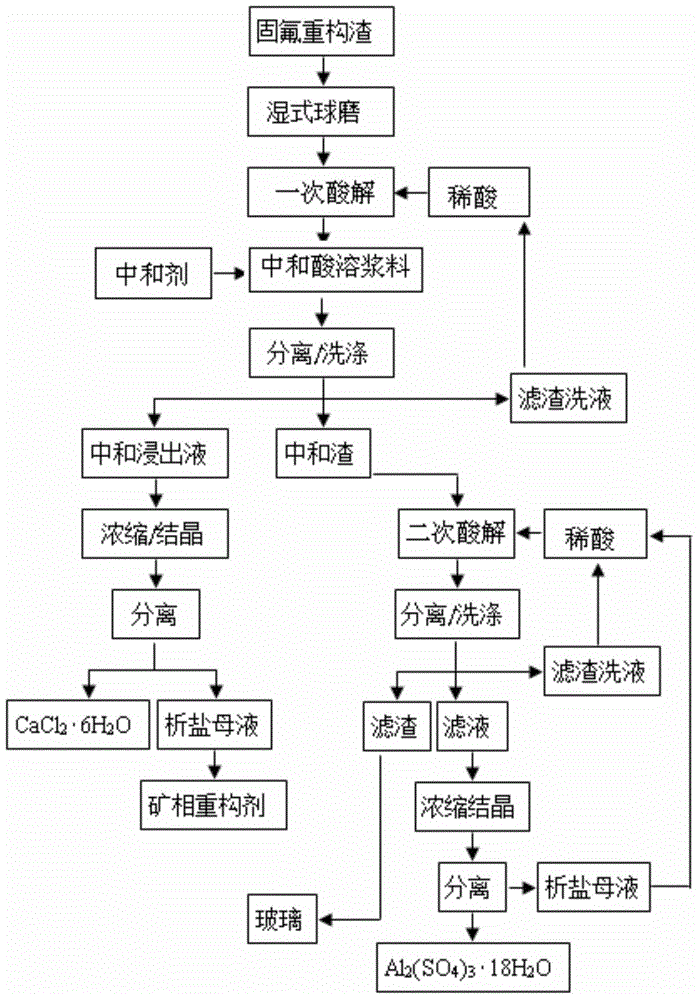

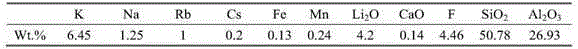

Method for treatment and resource utilization of alkali metal slag extracted through lepidolite solid fluorine reconstruction

ActiveCN105039699AMaximize utilizationLower melting temperatureProcess efficiency improvementSlagResource utilization

The invention relates to a method for treatment and resource utilization of alkali metal slag extracted through lepidolite solid fluorine reconstruction. The extracted alkali metal slag comprises slag components acquired after extracting one or more compounds of Li, K, Rb and Cs metal elements under the condition that F in lepidolite ores is converted into CaF2 for lepidolite ore-phase reconstruction. The method includes the steps of primary acidolysis of solid fluorine reconstruction slag, calcium chloride neutralization, separation, recycling and secondary acidolysis, and aluminum sulfate recycling. The alkali metal slag extracted through lepidolite solid fluorine reconstruction comprises most calcium silicoaluminate, fluorite, a small amount of sodium silicoaluminate and the like, a reconstruction agent is recycled through primary diluted acid leaching, by-products like aluminum salt are extracted through secondary diluted acid leaching, the calcium content in the slag is reduced, the plasticity of tailings is improved, the slag is directly used for raw materials of glass ceramics, ceramics, environment-friendly cement, building blocks and the like, the economic value of the slag is improved, and the comprehensive use efficiency of lepidolite is increased.

Owner:JIANGXI HZONE LITHIUM TECH

Coal dust suppressant

The invention relates to a coal dust suppressant which comprises a film-forming component, a wetting component, a coagulating component, carboxymethyl starch, chitosan, lauroamide propyl betaine, an auxiliary component and water for preparation, totally 100 parts by weight; the film-forming component is obtained by mixing lactic acid ring opening epoxy resin modified waterborne polyurethane and guar gum in a weight ratio of 0.15: 1; the wetting component is prepared by mixing TMDD, sodium dodecyl benzene sulfonate and a wetting agent ST-83 in a weight ratio of 0.02: 1: 0.06; the coagulating component is prepared by mixing anionic polyacrylamide, polyaluminum chloride and hydroxypropyl methyl cellulose in a weight ratio of 0.1: 0.4: 1; and the auxiliary component is prepared by mixing sodium silicoaluminate and sodium carbonate in a weight ratio of 1: 2.5. The sprayed dust suppressant can quickly form a high-strength film on the surface of the coal, is good in moisturizing property and can be fully degraded.

Owner:北京奥洁鼎森新能源科技有限公司

Acid soil amendment and preparation method thereof

InactiveCN105524619ARaise the pHShort cycleOther chemical processesOrganic fertilisersSodium BentoniteSilicon dioxide

The invention relates to an acid soil amendment and its preparation method. the soil amendment contains the following ingredients (by weight): 4-12 parts of silicon dioxide, 1-6 parts of calcium oxide, 3-10 parts of biochar, 3-8 parts of lignin, 2-6 parts of urea, 2-6 parts of sodium silicoaluminate, 1-4 parts of organic bentonite, 0.3-0.7 part of polymaleic anhydride, 0.5-1 part of hydrogen peroxide, 0.3-0.7 part of beta-cyclodextrin, 0.4-1 part of phosphatidase, 0.2-0.8 part of powder of Chinese prickly ash and 0.2-0.8 part of sweet potato powder. The soil amendment provided by the invention can effectively raise pH value of acid soil and improve the defect of short period of soil. Meanwhile, the acid soil amendment can effectively kill noxious bacteria in soil and also can effectively reduce content of heavy metal ion in soil.

Owner:JIANGSU GAIYA ENVIRONMENTAL SCI & TECH CO LTD

Process for enhancing yield of sodium aluminosilicate molecular sieves during synthesis

InactiveUS20050158237A1Increase productionReduce loadAluminium compoundsFaujasite aluminosilicate zeoliteMolecular sieveSodium silicoaluminate

The present invention relates to a process for enhancing the yield of molecular sieve zeolite during the synthesis from a sodium aluminosilicate reaction mixture, said process comprising the step of adding at an intermediate stage of crystallization a source of aluminum to the sodium aluminosilicate reaction mixture and allowing the mixture to crystallize.

Owner:INDIAN OIL CORPORATION

Method for reducing contamination of high-sodium coal

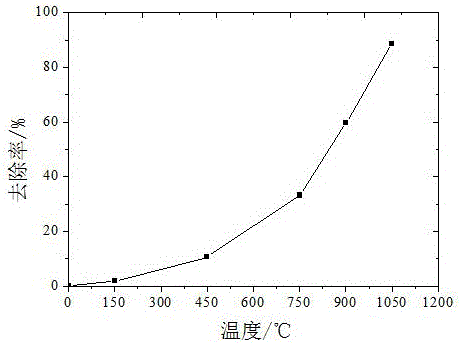

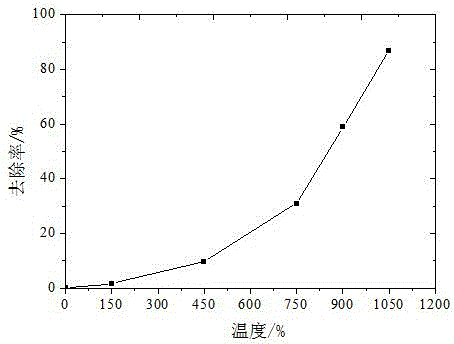

InactiveCN105670732ASolve contaminationSolve slaggingSolid fuelsLump/pulverulent fuel preparationHigh sodiumSodium silicoaluminate

The invention relates to a method for reducing contamination of high-sodium coal. The method comprises the following steps: breaking the high-sodium coal and an ash fusion point regulating agent and screening, then mixing the high-sodium coal with the ash fusion point regulating agent so that the ash composition of the mixture meets certain conditions, then putting the mixture into a boiler for burning, and controlling the temperature and excess air coefficient of the burning boiler; and starting a boiler slag removing system for removing slag. The method has the advantages that the high-sodium coal is combined with the ash fusion point regulating agent in different ratios, so that the composition ratio of each ash of a mixed ash sample is changed, the ratio of contents of various elements is regulated, especially the ratio of silicon and aluminum elements is improved, an ash fusion point of the mixed ash sample rises, the sodium element migrates into sodium silicate and sodium silicoaluminate and is discharged outside along with coal residues, and thus the problems of contamination, scorification and corrosion of the high-sodium coal during burning in the boiler are solved; and meanwhile, the technology is simple, the operation is safe, and the investment is low.

Owner:TAIYUAN UNIV OF TECH

Process for enhancing yield of sodium aluminosilicate molecular sieves during synthesis

InactiveUS20070059238A1Increase productionReduce loadAluminium compoundsFaujasite aluminosilicate zeoliteMolecular sieveSodium silicoaluminate

The present invention relates to a process for enhancing the yield of molecular sieve zeolite during the synthesis from a sodium aluminosilicate reaction mixture, said process comprising the step of adding at an intermediate stage of crystallization a source of aluminum to the sodium aluminosilicate reaction mixture and allowing the mixture to crystallize.

Owner:INDIAN OIL LIMITED A

Building adhesive and preparation method thereof

The invention provides a building adhesive and a preparation method thereof. The building adhesive is prepared from following components, by weight, 30-40 parts of cement, 7-15 parts of re-dispersible latex powder, 18-24 parts of glutinous rice flour, 15-25 parts of pottery sand, 6-12 parts of epoxy resin, 15-25 parts of desulfurization gypsum, 0.3-0.8 parts of sodium carboxymethylcellulose, 5-12 parts of sodium silicoaluminate, 4-8 parts of rosin, and 3-7 parts of nylon fiber. The building adhesive has reasonable formula, is easy to prepare and is convenient to transport. When being used, the building adhesive can be prepared by oneself and is easy and convenient to use. The building adhesive has excellent water resistance and corrosion resistance, is convenient to construct, has wide application range, can be bonded to concrete, brick and stone, wood and steel structures, and can be used for bricklaying, brick making, and wall and floor tile adhesion for buildings.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

Wall paint

ActiveCN102827523AHigh hiding powerEfficient smellAntifouling/underwater paintsPaints with biocidesAntibiosisChemical reaction

The invention provides a wall paint which comprises water, titanium pigment, a natural inorganic material which can adsorb oxymethylene, a combining sodium silicoaluminate and a polymer emulsion of functionality group with a molecular structure which is H2N-CO-NH2. The wall paint provided by the invention comprises the following steps of: firstly carrying out rapid physical adsorption on the oxymethylene through the natural inorganic material and the combining sodium silicoaluminate, then, utilizing the functionality group with the molecular structure which is H2N-CO-NH2 and the oxymethylene to generate a chemical reaction to degrade the oxymethylene, generating an innocuous substance and water, achieving the effect of fully eliminating aldehyde and protection decoration. In addition, polarity which is negative ion nature mineral and an accessory ingredient is also utilized, hydroxy negative ion can realize permanence release, the action of high efficiency antibiosis and eliminating peculiar smell is achieved, and finally, the novel wall paint is formed and has the advantages of fully eliminating aldehyde, protecting wall face, and has a good decorative effect.

Owner:ASIA PAINT SHANGHAI

Composite cement

The invention discloses composite cement, which relates to a building material and is made from the following raw materials in weight proportions: red mud 10-70 parts, cement clinker 10-15 parts and sulfate 15-40 parts. The sulfate may be the mixture of more than one selected from phosphogypsum, coal ash, silica slag and sodium silicoaluminate. The weight proportions of components of the sulfate mixture are as follows: phosphogypsum 2-10 parts, coal ash 5-20 parts, silica slag 5-15 parts and sodium silicoaluminate 3-10 parts. The invention is used for cement production.

Owner:周士合

Lightweight fly ash-based sodium aluminum silicate plate and preparation method thereof

InactiveCN104987019ASimple preparation processImprove performanceSolid waste managementFiberAluminum silicate

The present invention discloses a lightweight fly ash-based sodium aluminum silicate plate and a preparation method thereof, wherein the raw materials of the plate comprise, by mass, 50-80 wt.% of silicon-aluminum solid waste, 1-10 wt.% of easily-dispersed fibers, 20-40 wt.% of an alkaline activator, 0.1-1 wt.% of calcium stearate, 0.1-1 wt.% of an efficient water reduction agent, and the like, wherein the fly ash in the solid waste accounts for 70-100 wt.%. According to the present invention, mixing, stirring, casting, vacuum drying, low-temperature curing, demolding, cutting and burnishing are performed to prepare the lightweight fly ash-based sodium aluminum silicate plate; the process does not require lime, cement and other raw materials and does not require high temperature and high pressure; the atmospheric pressure and low temperature (60-80 DEG C) curing is performed to prepare the product; and the solid waste is used so as to reduce the cost and improve the safety production capability and the production efficiency.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Evenly dispersed aluminum section production lubricant

The present invention discloses an evenly dispersed aluminum section production lubricant, and the evenly dispersed aluminum section production lubricant is obtained from the following parts by weight of raw materials: 2-4 parts of molybdenum disulfide, 1-2 parts of sodium molybdate, 0.5-0.9 part of alkyl phenol polyoxyethylene ether, 3-7 parts of rapeseed oil, 1-2 parts of choline, 3.5-5.5 parts of industrial white oil, 20-30 parts of modified graphite powder, 4-6 parts of colloidal graphite, 1-2 parts of aluminum dihydrogen phosphate, 8-16 parts of paraffin oil and 1-2 parts of sodium aluminosilicate. The evenly dispersed aluminum section production lubricant has good homogeneity and cohesion, can be repeatedly removable without damaging of a lubricating film, can work at high and low temperature environment, and ensures that lubricating parts in working conditions are lubricant, zero-resistant, anti-corrosion, scuffing, and the like, and the evenly dispersed aluminum section production lubricant can be applied to aluminum section extrusion machine lubrication, and can also be used on lubrication of parts of other fields.

Owner:DANGTU WEISIGONGCHUANG IND PROD DESIGN CO LTD

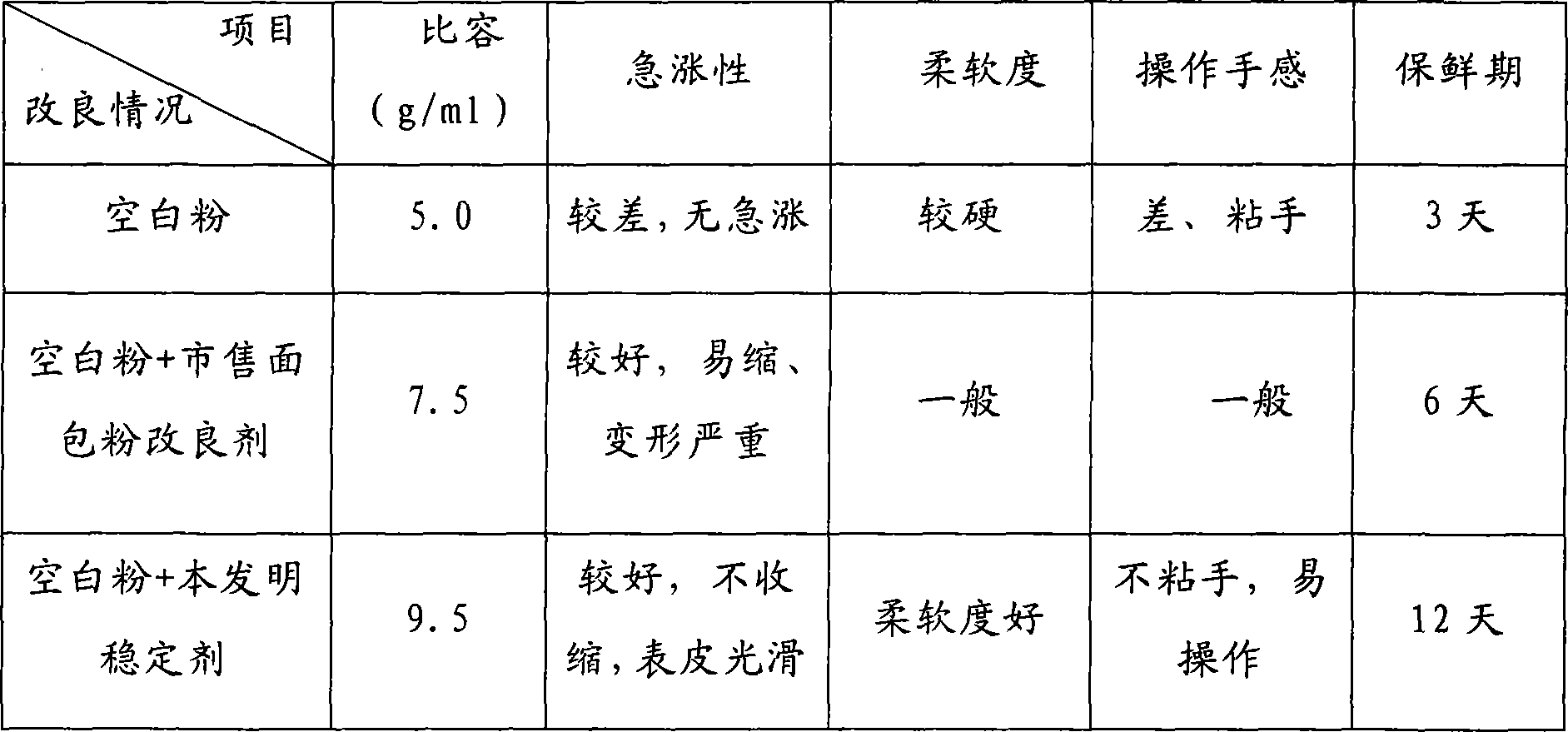

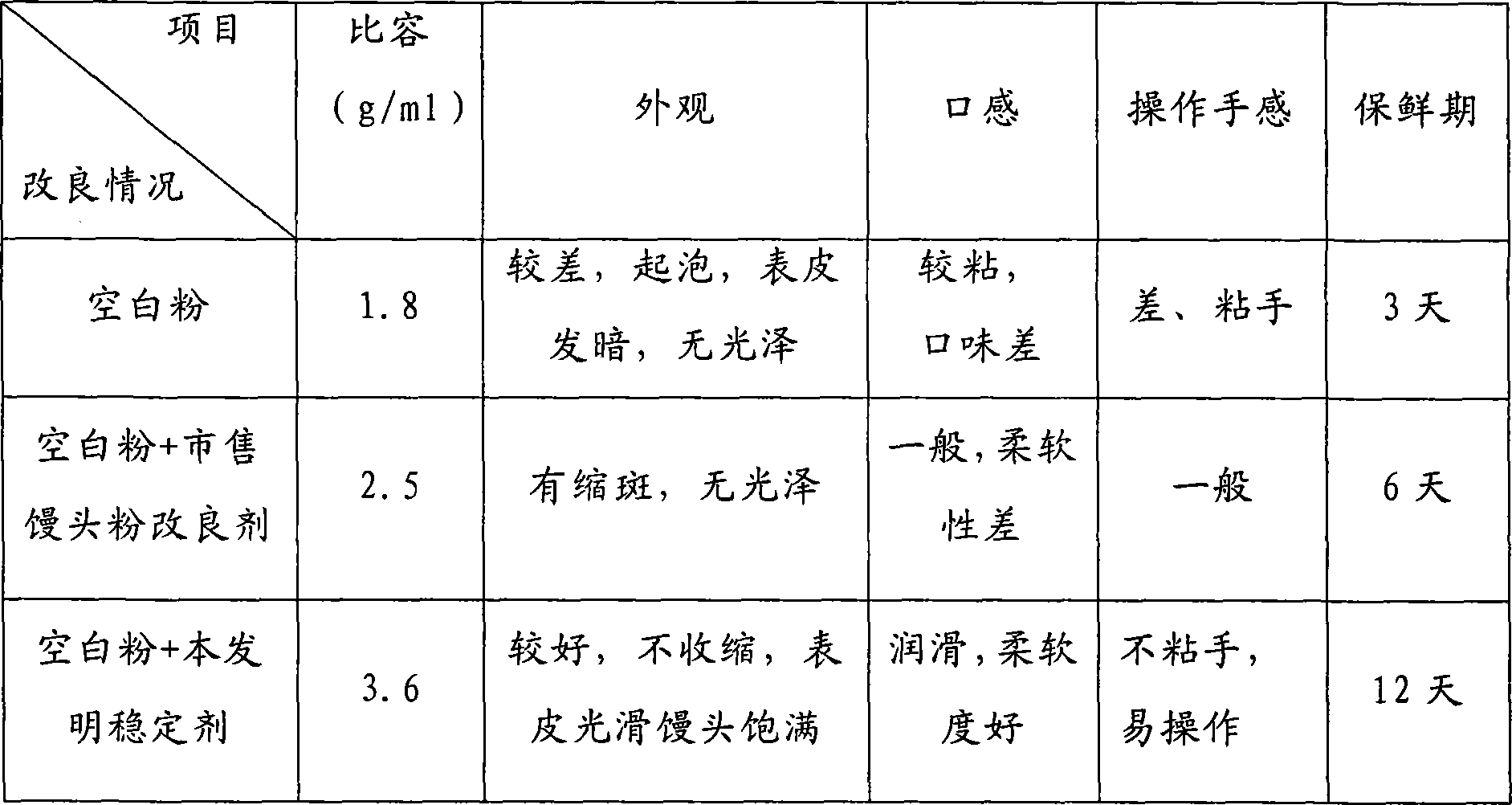

Flour quality stabilizing agent

The invention provides a flour quality stabilization agent which is prepared according to the following materials with a weight portion of: 100 to 1000 portions of a mixture of stearoyl calcium lactate and stearoyl sodium lactate, 20 to 500 portions of sodium benzoate, 10 to 1000 portions of sodium polyacrylate, 0.5 to 20 portions of VB6, 5 to 100 portions of phaseomannite, 2 to 15 portions of aneurine and 10 to 20 portions of Vc; wherein, the stearoyl calcium lactate occupies 50 to 80 percent of the weight of the mixture and the stearoyl sodium lactate occupies 20 to 50 percent of the weight of the mixture. The stabilization agent also comprises 10 to 1000 portions of a mixture of starch and anti-caking agent calculated by weight portions, wherein, the anti-caking agent is a compound of one or a plurality of silicon dioxide, sodium silicoaluminate, talcum powder, magnesium stearate, light calcium carbonate, polyethyleneglycol or fibrin powder. The flour quality stabilization agent can make up the nutrient losses caused by the flour machining process, improve the machining performance of the flour, amend the integral quality of the flour, improve the nutrition value of the flour, amend the internal organization mechanisms of the flour, increase the stability of the flour and improve the taste and guarantee period of food.

Owner:河南兴泰科技实业有限公司

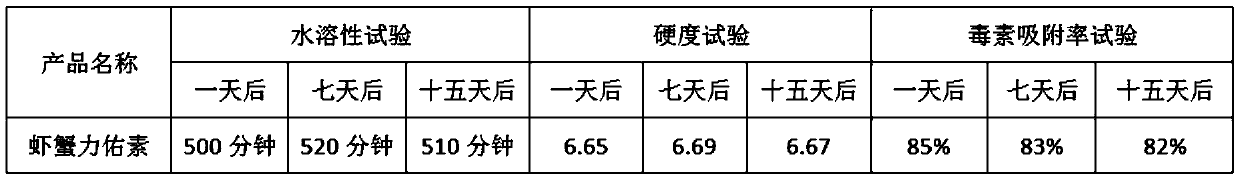

Quality improver for shrimp and crab feeds and preparation method thereof

InactiveCN110200172AActive ingredients are stableHelp shapeAccessory food factorsCelluloseAluminum silicate

The invention relates to a compound feed, relates to a quality improver for shrimp and crab feeds and also designs a preparation method of the quality improver for shrimp and crab feeds. Attapulgite is sun-curd or dried with a hot blast furnace so that water content is reduced to 12 and below; lignosulfonates having a concentration of 3%, a stabilizer, sodium aluminum silicate, cellulose and sorbitan fatty acid esters are added to the dried attapulgite, so that the attapulgite is acidified completely before pressure filtering; drying is then performed at 85 DEG C until the water content dropsto 10 and below; after passing inspection, the dried material is milled; the attapulgite powder is weighed and rechecked; rechecked alpha-starch, a surfactant, colloid and agar are weighed and premixed with the attapulgite powder so that the attapulgite powder is mixed well with the additives; after inspection, the attapulgite powder is a finished product which is then pacakaged and warehoused. The quality improver and the preparation method herein have the advantages that active ingredients in feeds can be stabilized, and powder in processing, storage and transporting processes can be lessened.

Owner:江苏神力特生物科技股份有限公司

Environment-friendly paint

An environment-friendly paint comprises the following components by weight: 5 to 26 grams of sodium silicoaluminate, 1 to 6 grams of hydroxypropionic acid, 7 to 21 grams of water, 12 to 37 grams of titanium dioxide, 3 to 13 grams of lactic acid, 6 to 17 grams of kaolin, 7 to 23 grams of calcium oxide, 7 to 21 grams of alumina, 8 to 11 grams of antifoaming agent, and 5 to 14 grams of phenylalanine. The environment-friendly paint has a high viscosity, can prevent rot and mildew, eliminates the bubbles, effectively overcomes the shortages of irritant odor and harms to human body, and is more environment-friendly.

Owner:潘海楠

Combined remediation method for heavy metal contaminated soil

InactiveCN106583439AGood restorativeImprove repair effectContaminated soil reclamationOrganic fertilisersAluminatePhosphate

The invention discloses a combined remediation method for heavy metal contaminated soil. The combined remediation method for the heavy metal contaminated soil comprises the steps that a soil remediation agent is prepared after oyster shell powder, coal ash, cow dung, calcium molybdate, calcium aluminate, calcium superphosphate, calcium oxalate, (trimethylsilyl) phosphate, palygorskite, sodium silicoaluminate, poly dimethyl diallyl ammonium chloride, alkali aluminum sodium carbonate, barium metaborate, sodium selenite, poly(3,4-ethylenedioxythiophene), potassium ferrite and aluminate, and bergapten are weighed and mixed by weight; the heavy metal contaminated soil is crushed and mixed with water and the soil remediation agent, and pre-remediated soil is obtained 1-4 months later; and the pre-remediated soil is loosened and remediated through enrichment of earthworms. According to the combined remediation method for the heavy metal contaminated soil, through the combined remediation of the soil remediation agent and the earthworms, the heavy metal concentration in the soil is promoted to be decreased greatly, and the soil can be used for safety production as soon as possible; and the remediation effect is stable, the remediation time is short, and fertilize required for growth of plants can be provided. The remediation efficiency for the heavy metal contaminated soil is improved on the whole.

Owner:沃邦环保有限公司

Copper ion contaminated acidic soil remediation agent and preparation method thereof

InactiveCN105368457AGood restorativeImprove repair effectAgriculture tools and machinesOrganic fertilisersSludgeSodium aluminate

Owner:JIANGSU GAIYA ENVIRONMENTAL SCI & TECH CO LTD

Impregnation auxiliary for powder zinc impregnation

InactiveCN110343997AShorten the timeLow temperature of sherardizingSolid state diffusion coatingPowder mixtureAdhesive

The invention discloses an impregnation auxiliary for powder zinc impregnation. The impregnation auxiliary for powder zinc impregnation belongs to a power mixture which mainly comprises, by weight, 10-25% of aluminum oxide serving as a high-temperature-resistant adhesive for zinc powder, 30-60% of ammonia chloride serving as a furnace interior oxygen scavenger, 15-25% of zinc chloride serving as an activating agent for workpieces to be impregnated, 5-18% of lanthanum hydroxide serving as an impregnation assisting catalyst and 10-16%fo sodium silicoaluminate serving as a moistureproof anti-caking agent of the impregnation auxiliary. The impregnation auxiliary provided by the invention can remove moisture and unnecessary oxygen in a furnace pipe and reduce zinc powder oxidation, can activatethe surfaces of workpieces to enable metal activated matrixes of the workpieces to be exposed and facilitate diffusion of zinc atoms in iron matrixes and meanwhile has the catalytic effect.

Owner:ZHENGZHOU ZHONGYUAN LIDA NEW MATERIAL CO LTD

Non-phosphorus and non-4A zeolite detergent

InactiveCN1763161AStrong exchange abilityHigh speedInorganic/elemental detergent compounding agentsSurface-active detergent compositionsWater sourcePhosphate

The present invention relates to detergent, and discloses one kind of detergent without surfactant, soap, phosphate and 4A zeolite. The detergent is complex salt of sodium aluminosilicate and may be named as Na-P type detergent molecular sieve. It is prepared with flyash as main material, and through alkalization with sodium hydroxide to produce sodium silicoaluminate colloid, further reaction with limestone powder and coal gangue powder, ageing in alkali solution and roasting to obtain the quick soluble white crystal complex salt. The detergent may be further compounded into washing agent, washing powder or defatting agent with less pollution to water source. The present invention is environment friendly and low in cost.

Owner:崔官栓 +1

Instant coconut powder and processing method thereof

InactiveCN108651901AAvoid stickingIncrease instant speedSugar food ingredientsFood ingredient as anti-caking agentCarrageenanAnticaking agent

The invention discloses instant coconut powder and a processing method thereof. The instant coconut powder is prepared through the steps of preparing coconut flesh, preparing coconut water, freezing the prepared coconut water, preparing materials, performing mixing, performing packaging and the like. Carrageenan or pectin is selected as an instant agent, polyethyleneglycol monooleate or rosin-polythylene oxide ester is selected as an emulsifying agent, and sodium silicoaluminate is selected as an anticaking agent, so that cohesion of the instant coconut powder in the storage process can be avoided, besides, the quick-dissolving speed of the instant coconut powder is increased, and the instant coconut powder is convenient for users to drink. Through a freeze drying technique and controllingthe processing environment of the instant coconut powder, damage of vitamins and amino acids contained in the coconut powder is avoided, and the quality of the instant coconut powder is guaranteed; and besides, the cohesion of the coconut powder in the storage process can be avoided, the quick-dissolving speed of the coconut powder is increased, and the coconut powder is drunk in a direct brewingmanner.

Owner:东莞市椰乡小镇实业发展有限公司

Method for preparing superfine alumina silicate

ActiveCN1915813AReduce production linksReduce manufacturing costAluminium silicatesSodium silicoaluminateAluminum silicate

This invention relates to a method for preparing ultrafine aluminum silicate. The method comprises: (1) mixing bauxite powder and sodium carbonate at Na2O / Al2O3 ratio of 1.2-1.6, adding limestone powder (1-10 wt.% of bauxite) and quartz sand powder (2-15 wt.% of bauxite), and calcining to obtain a clinker; (2) dissolving the clinker to obtain a crude solution; (3) adding one of calcined kaolin powder, amorphorus sodium aluminosilicate and ultrafine aluminum silicate (0.5-2 wt.% of the crude solution), synthesizing and aging; (4) filtering the aged reaction solution to obtain a filter cake; (5) washing the filter cake, drying, and pulverizing by air flow to obtain ultrafine aluminum silicate product. The method has such advantages as high adaptability of raw materials, high product quality and purity, good product dispersibility, no wastewater discharge and no pollution.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

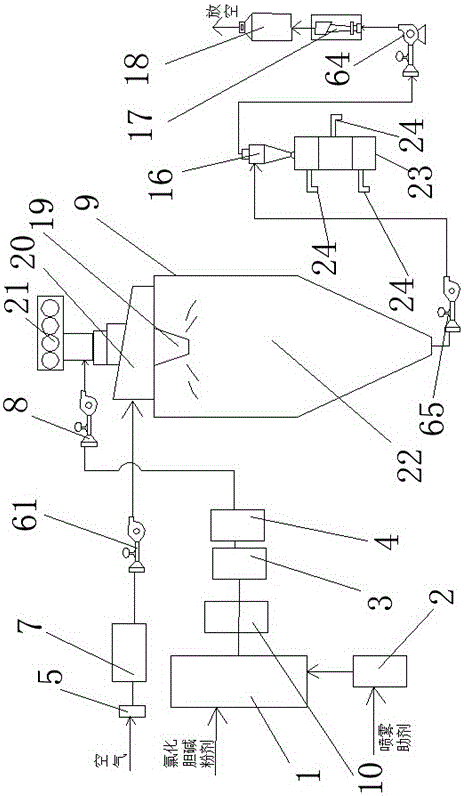

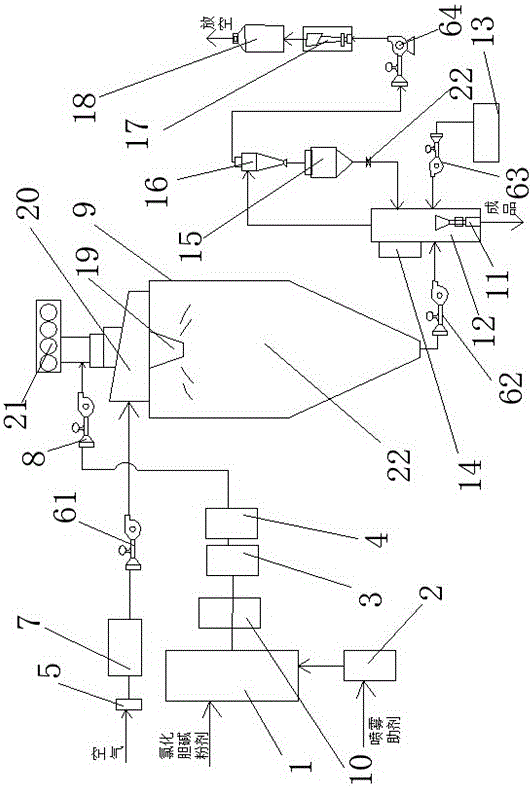

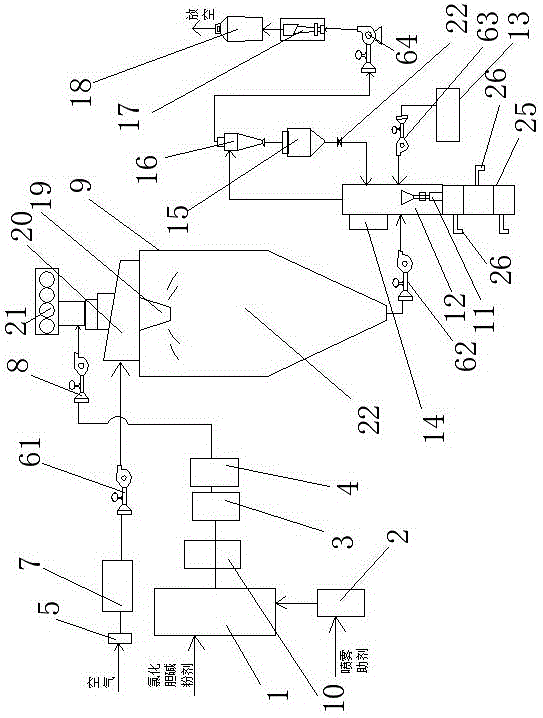

Preparation method and preparation device of choline chloride powder

PendingCN105876164AMask or get rid of bad odorsRelease stabilityBiocidePlant growth regulatorsPhosphateWater chlorination

The invention discloses a preparation method and a preparation device of choline chloride powder. The preparation method includes: obtaining choline chloride water of 50-80% in weight percentage of choline chloride; adding a spray auxiliary into the choline chloride water, and mixing and stirring well, wherein adding quantity of the spray auxiliary is 2-15% of weight of the choline chloride water; pumping the choline chloride water added with the spray auxiliary into spray drying equipment for spray drying; step 4, feeding choline chloride dried powder into a mixing tank, adding one of or a mixture of multiple of potassium ferrocyanide, sodium silicoaluminate, tricalcium phosphate, silica, microcrystalline cellulose and calcium stearate accounting for 3-30% of weight of the choline chloride dried powder, and stirring and mixing to obtain the choline chloride powder. The preparation device comprises an air feeding system, a liquid feeding system, a spray drying system, a mixing system, a tail gas treatment system and a pipeline. The preparation method and the preparation device have the advantages of quickness in drying and low energy consumption.

Owner:SHANDONG AOCTER CHEM

Non-stick paint

InactiveCN105273510AImprove insulation effectEasy to useProtein coatingsSodium aluminateMagnesium stearate

The invention provides non-stick paint. The non-stick paint is prepared from 5-19 g of collagen hydrolysate, 6-8 g of polypropylene, 9-14 g of ethyl acetate, 16-27 g of methyl alcohol, 8-12 g of ethyl alcohol, 4-22 g of trimethylbenzene, 4-9 g of titanium dioxide, 4-19 g of sodium silicoaluminate, 8-11 g of aluminum oxide, 5-8 g of magnesium stearate, 7-19 g of ferric oxide, 7-21 g of ferroferric oxide, 7-14 g of ammonium heptamolybdate and 6-57 g of iron powder. The size of the iron powder ranges from 50 meshes to 120 meshes. The iron powder is added to the paint, and the heat preservation performance of the paint can be remarkably improved. The iron powder is added to the paint, the heat preservation effect of the non-stick paint can be remarkably improved, energy is saved, consumption is reduced, other indexes of the non-stick paint are not affected, and use is more convenient.

Owner:郭亚楠

Preparation method of aluminum silicate-white carbon black composite filler

ActiveCN111533951AHigh extinction efficiencyHigh densityMaterial nanotechnologySilicaSodium silicoaluminateNanoparticle

The invention discloses a preparation method of an aluminum silicate-white carbon black composite filler. The preparation method comprises the following steps: adding water and a silicon compound intoa reaction kettle, stirring, heating to 60-90 DEG C, and adding the silicon compound and an acidifying agent to react until the pH value of the reaction solution is 8.0-11.0; after curing, adding analuminum compound solution to continuously react, adding a precipitator to generate sodium aluminosilicate gel, and then continuously curing to obtain a sodium aluminosilicate nanoparticle suspension;adding a silicon compound into the suspension; stirring to make pH equal to 8-11, heating to 60-90 DEG C to obtain a silica reaction substrate, adding a silicon compound and an acidifying agent for 1-2 hours at the same time, wherein the pH value is maintained to be 8-11, stopping adding the silicon compound after slurry of the nano sodium aluminosilicate-white carbon black composite filler is obtained, continuously adding the acidifying agent until the pH value is 3.0-6.0, and stopping adding so as to obtain a suspension of the nano sodium aluminosilicate-white carbon black composite filler;and filtering, washing and high-temperature quick-drying the suspension to obtain the nano sodium aluminosilicate core and silicon dioxide coated shell composite filler with high extinction efficiency, good dispersity and storage stability.

Owner:FUJIAN ZHENGSHENG INORGANIC MATERIAL

Food additive

InactiveCN103931971AGood colorImprove the preservation effectFood preservationAcidic food ingredientsFood additiveBeta-Carotene

The invention relates to the field of additives and in particular to a food additive which comprises beta-carotene, lutein, pectin, L-ascorbic acid, sodium silicoaluminate, tricalcium phosphate, microcrystalline cellulose, inosinic acid, L-amanita tain glycine. The food additive provided by the invention contains multiple coloring agents, anti-caking agents, preservatives and the like and can be comprehensively added into food, and then the taste, the color and the preservation property of the food are improved, and moreover the food additive provided by the invention is low in cost and simple to use.

Owner:王和绥

Fresh flower preservative

The invention discloses a fresh flower preservative which includes following components: sodium silicoaluminate, activated charcoal, potassium permanganate, iron powder, vinegar, saccharose, citric acid, 8-hydroxyquinoline sulfate and water. The fresh flower preservative is long in preservative time and can effectively prolong the preservative time of fresh flower.

Owner:肖哲西

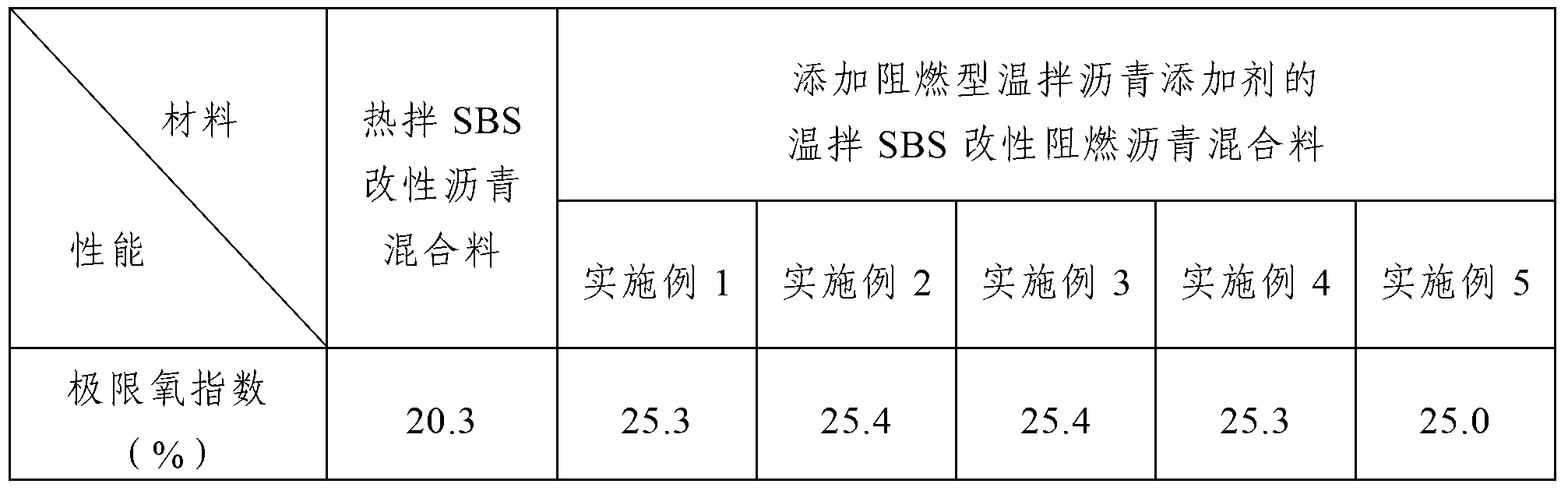

Fire-retardant warm-mixed asphalt additive

ActiveCN103265198AWell mixedSimple preparation processClimate change adaptationPentaerythritolSodium silicoaluminate

The invention provides a fire-retardant warm-mixed asphalt additive which is formed by mixing and carrying out ball-milling on the following raw materials in parts by weight: 21-26 parts of sodium silicoaluminate, 20-23 parts of ammonium polyphosphate, 4-8 parts of melamine, 1-4 parts of pentaerythritol, 13-16 parts of diatomite and 0.3-0.6 part of a dry powder interfacial agent. According to the fire-retardant warm-mixed asphalt additive, the limited oxygen index of an asphalt mixture can achieve more than 25 percent, the mixing and compacting temperature of the asphalt mixture can be reduced by more than 20 DEG C under the premise that the performance of the asphalt mixture is not influenced, and the fire-retardant warm-mixed asphalt additive can be widely applied to asphalt mixture construction in various climates of regions.

Owner:CHANGAN UNIV

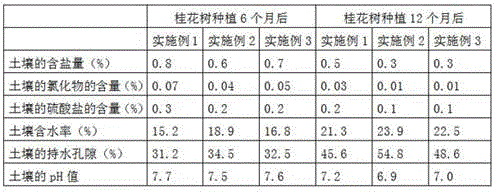

Method for carrying out raw soil greening on secondary salinized saline and alkaline land by using amino acid salt-containing soil conditioner

The invention relates to a method for carrying out raw soil greening on secondary salinized saline and alkaline land by using an amino acid salt-containing soil conditioner. The soil conditioner comprises, by weight, 31-33 parts of fermented pigeon manure, 10-13 parts of decomposed rice straw powder, 3-5 parts of fly ash, 3-5 parts of phosphate rock powder, 2-4 parts of bentonite, 2-4 parts of calcium superphosphate, 1-3 parts of manganese hypophosphite, 1-3 parts of adipic acid, 3-5 parts of amino acid salt, 0.5-0.7 parts of compound sodium nitrophenolate, 0.5-0.7 parts of rapin, 0.5-0.7 parts of a wolfberry fruit extract product, 3-5 parts of sodium silicoaluminate, 0.5-0.7 parts of a starch grafted styrene sulfonic acid copolymer, 1-3 parts of ammoniated superphosphate, 1-3 parts of chelated iron, 1-3 parts of chelated zinc, 0.1-0.3 parts of Bacillus amyloliquefaciens, 0.1-0.3 parts of Bacillus megaterium, 0.1-0.3 parts of Bacillus licheniformis, 0.1-0.3 parts of microzyme, 0.1-0.3 parts of Azotobacter vinelandii and 0.1-0.3 parts of Trichoderma Longibrachiatum.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com