Fire-retardant warm-mixed asphalt additive

A technology for warm mix asphalt and additives, which is applied in the field of road asphalt materials, can solve the problems of unfavorable quality control by manual feeding method, cumbersome metering and sub-packaging process, and small amount of single additive, and achieves low production cost, good high temperature stability and high temperature stability. Effects of water damage resistance, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

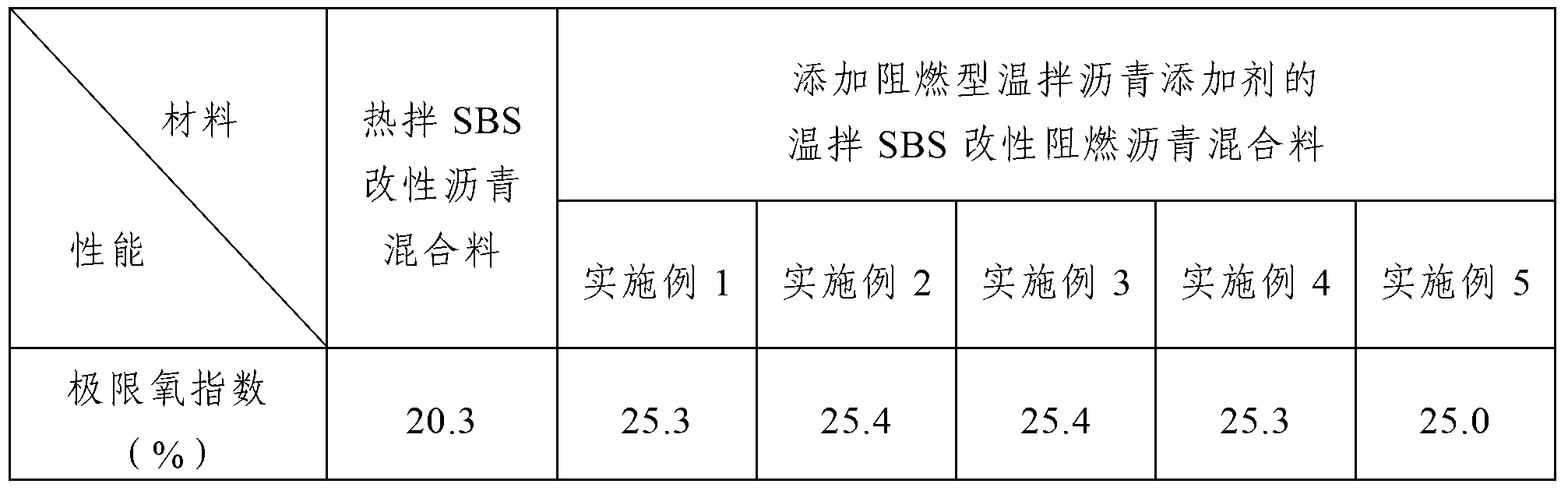

Embodiment 1

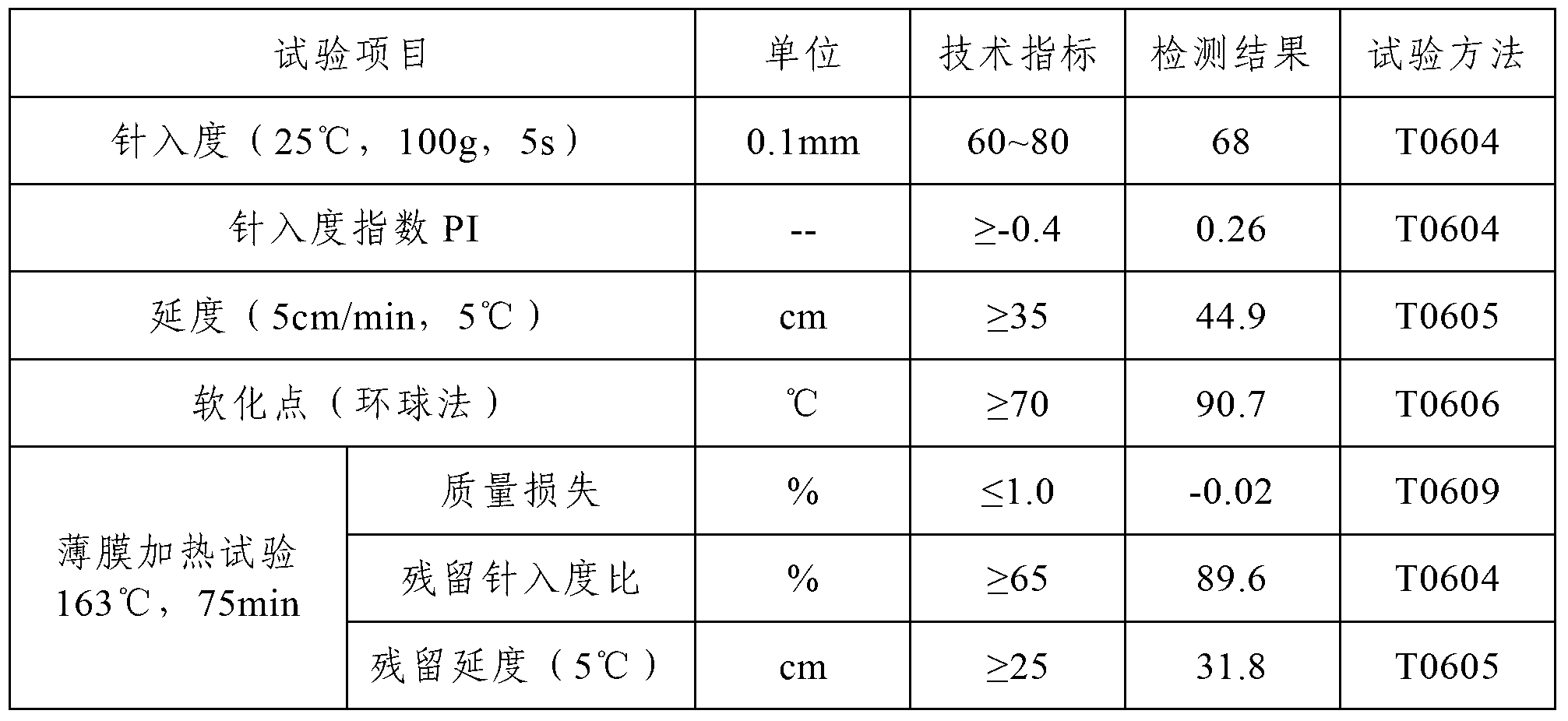

[0019] The flame retardant warm mix asphalt additive in this example is made by mixing and ball milling the following raw materials in parts by weight: 23 parts of sodium aluminosilicate, 21 parts of ammonium polyphosphate, 6 parts of melamine, 2 parts of pentaerythritol, 14 parts of diatomaceous earth, dry powder interface 0.4 parts of agent; preferably, the dry powder interface agent is redispersible latex powder, the speed of the ball milling is 400r / min, and the time of the ball milling is 36min.

Embodiment 2

[0021] The flame-retardant warm-mix asphalt additive in this example is made by mixing and ball-milling the following raw materials in parts by weight: 24 parts of sodium aluminosilicate, 22 parts of ammonium polyphosphate, 5 parts of melamine, 3 parts of pentaerythritol, 15 parts of diatomaceous earth, dry powder interface 0.5 parts of agent; preferably, the dry powder interface agent is redispersible latex powder, the speed of the ball milling is 350r / min, and the time of the ball milling is 43min.

Embodiment 3

[0023] The flame retardant warm mix asphalt additive in this example is made by mixing and ball milling the following raw materials in parts by weight: 26 parts of sodium aluminosilicate, 23 parts of ammonium polyphosphate, 8 parts of melamine, 4 parts of pentaerythritol, 16 parts of diatomaceous earth, dry powder interface 0.6 part of agent; preferably, the dry powder interface agent is redispersible latex powder, the speed of the ball milling is 500r / min, and the time of the ball milling is 30min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com