Flour quality stabilizing agent

A flour quality and stabilizer technology, applied in dough processing, baking, food science and other directions, can solve the problems of prolonging the shelf life of flour, difficult to improve food grades, and poor stability, so as to improve the taste and shelf life, improve internal Organizational structure, the effect of highlighting substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

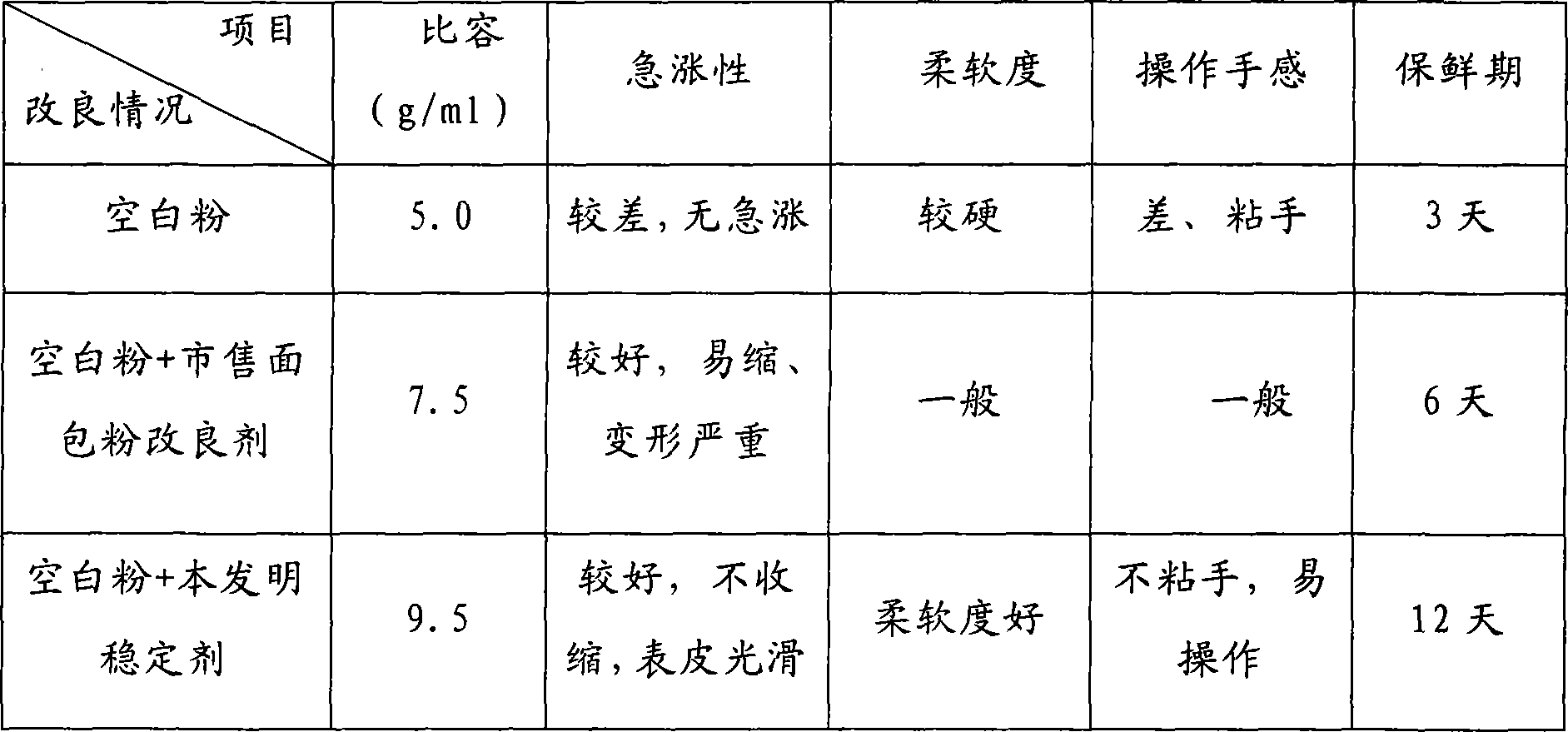

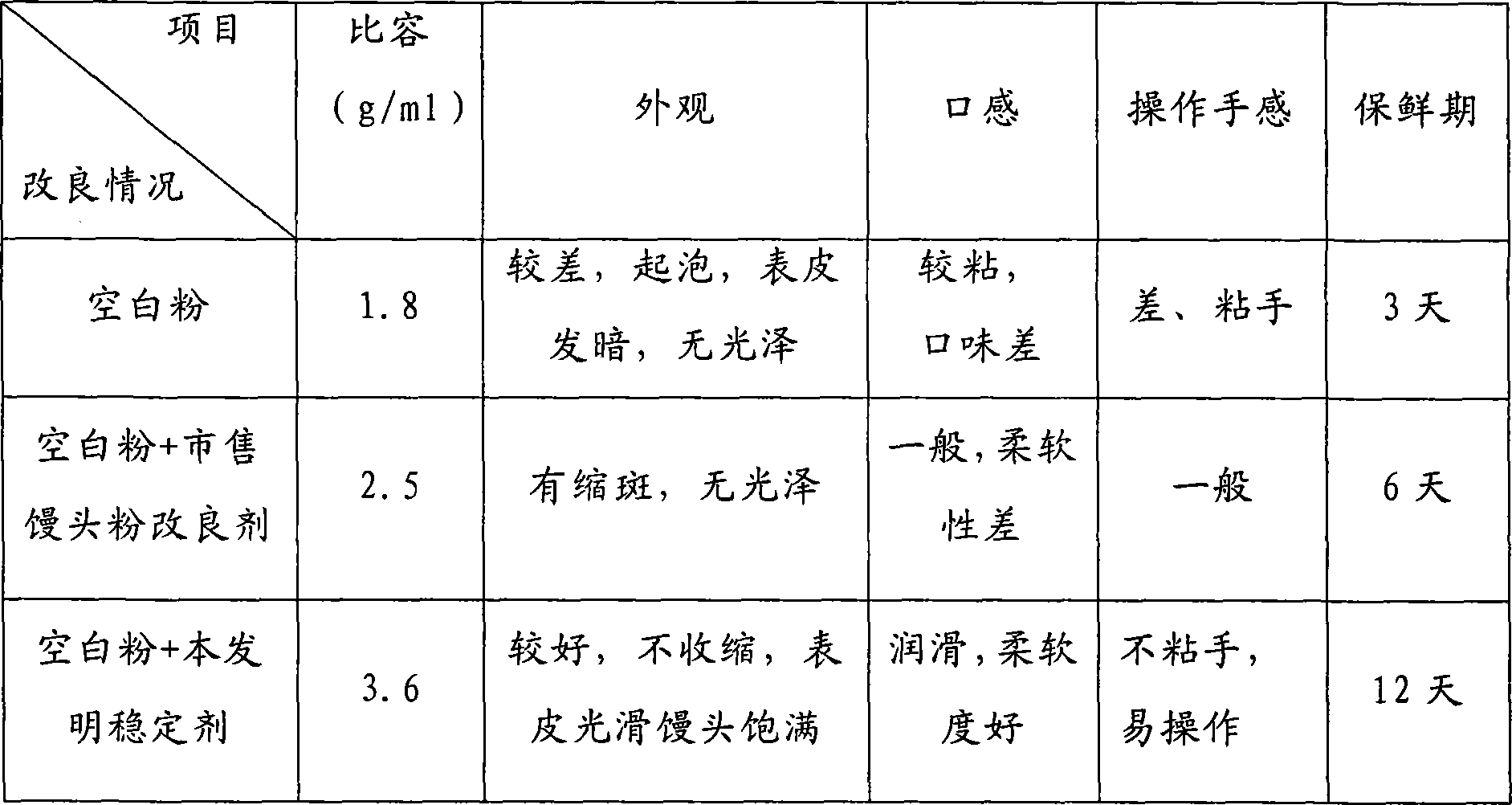

Examples

Embodiment 1

[0037] A flour quality stabilizer, which is made from the following raw materials in parts by weight: 50 parts of calcium stearoyl lactylate, 50 parts of sodium stearoyl lactylate, 20 parts of sodium benzoate, 10 parts of sodium polyacrylate, 0.5 parts of VB6 , 5 parts of inositol, 2 parts of thiamine, 10 parts of Vc, 20 parts of starch, 1 part of anticaking agent.

Embodiment 2

[0039] A flour quality stabilizer, the stabilizer is made of the following raw materials in parts by weight: 500 parts of calcium stearoyl lactylate, 500 parts of sodium stearoyl lactylate, 500 parts of sodium benzoate, 1000 parts of sodium polyacrylate, 20 parts of VB6 , 100 parts of inositol, 12 parts of thiamine, 20 parts of Vc, 200 parts of starch, 10 parts of anticaking agent.

Embodiment 3

[0041] A flour quality stabilizer, the stabilizer is made of the following raw materials in parts by weight: 100 parts of calcium stearoyl lactylate, 100 parts of sodium stearoyl lactylate, 400 parts of sodium benzoate, 500 parts of sodium polyacrylate, 10 parts of VB6 , 50 parts of inositol, 10 parts of thiamine, 10 parts of Vc, 100 parts of starch, 5 parts of anticaking agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com