Method for treatment and resource utilization of alkali metal slag extracted through lepidolite solid fluorine reconstruction

A technology of alkali metal and lepidolite, applied in the direction of improving process efficiency, can solve the problems of lack of research and comprehensive utilization of extraction of alkali metal slag, and achieve the advantages of resource utilization, reduction of melting temperature, and reduction of neutralizer dosage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

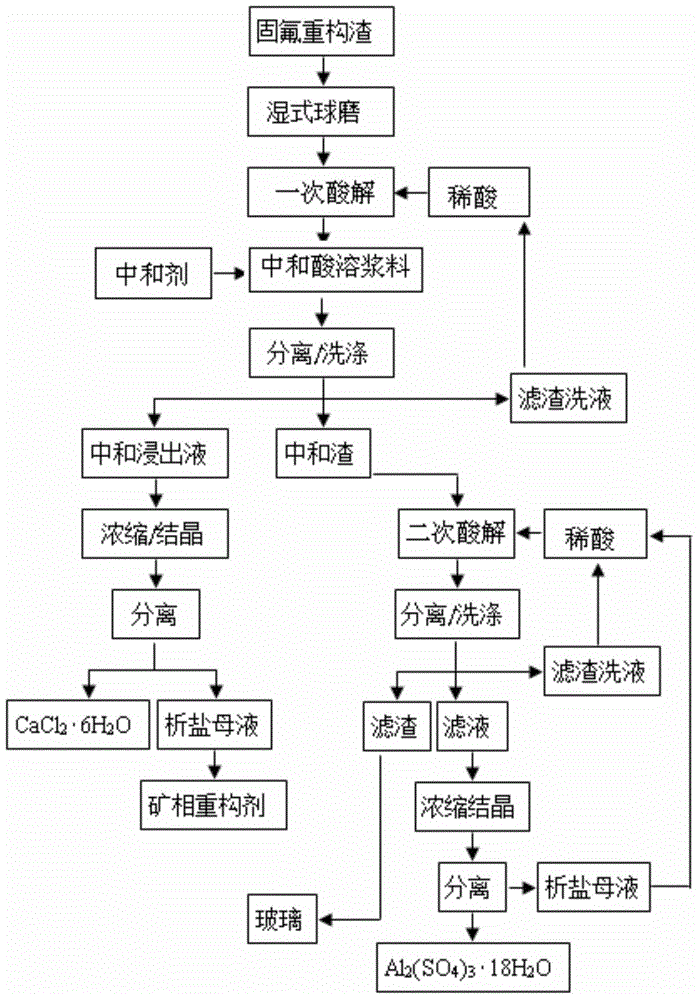

Method used

Image

Examples

Embodiment 1

[0042] Add dilute hydrochloric acid (1.2mol / L) and pretreated slag into the reactor at a mass ratio of 2:1 for acidolysis: raise the temperature to 60°C and stir for 45 minutes; detect the pH value of the acid-soluble slurry, and then add A small amount of neutralizer to control the pH to 4.5 for 30 minutes, then filter to separate CaCl 2 Solution, prepare CaCl by concentrating and analyzing salt 2 ﹒ 2H 2 O crystals, the salt precipitation mother liquor rich in Ca and alkali metal salts are directly used for mixing with lepidolite raw materials to form pellets, which is one of the main sources of mineral phase restructuring agent raw materials.

[0043] Dilute sulfuric acid (5wt.%) and reconstituted residue after drying treatment were added to the reaction kettle at a mass ratio of 5:1 for secondary acidolysis: the temperature was raised to 60°C and stirred for 30 minutes, and then filtered for liquid-solid separation. After countercurrent washing, the washing liquid is use...

Embodiment 2

[0049] Add dilute hydrochloric acid (0.96mol / L) and pretreated slag into the reactor at a mass ratio of 2.5:1 for acidolysis: raise the temperature to 80°C and stir for 60 minutes to detect the pH of the acid-soluble slurry, and then add a small amount of The neutralizer controls the pH to 4.5 and maintains it for 60 minutes, then filters and separates CaCl 2 Solution, prepare CaCl by concentrating and analyzing salt 2 ﹒ 2H 2 O crystals, the salt precipitation mother liquor rich in Ca and alkali metal salts are directly used for mixing with lepidolite raw materials to form pellets, which is one of the main sources of mineral phase restructuring agent raw materials.

[0050] Dilute sulfuric acid (6wt.%) and reconstituted residue after drying treatment were added to the reaction kettle at a mass ratio of 5:1 for secondary acidolysis: the temperature was raised to 70°C and stirred for 35 minutes, and then filtered for liquid-solid separation. After countercurrent washing, the ...

Embodiment 3

[0056] Add dilute hydrochloric acid (1.44mol / L) and pretreated slag to the reactor at a mass ratio of 3:1 for acidolysis: raise the temperature to 90°C and stir for 60 minutes to detect the pH of the acid-soluble slurry, and then add a small amount of The neutralizer controls the pH to 4.5 and maintains it for 60 minutes, then filters and separates CaCl 2 Solution, prepare CaCl by concentrating and analyzing salt 2 ﹒ 2H 2 O crystals, the salt precipitation mother liquor rich in Ca and alkali metal salts are directly used for mixing with lepidolite raw materials to form pellets, which is one of the main sources of mineral phase restructuring agent raw materials.

[0057] Dilute sulfuric acid (4wt.%) and the reconstituted residue after drying treatment were added to the reactor at a mass ratio of 4:1, heated to 90°C, stirred and reacted for 35 minutes, and then filtered for liquid-solid separation. The filter residue was washed in countercurrent, washed Liquid is used to dilu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com