Quality improver for shrimp and crab feeds and preparation method thereof

A quality improvement and feed technology, applied in animal feed, application, animal husbandry, etc., can solve problems that affect health, easy to absorb moisture, and problems, and achieve the effect of improving solvent resistance, stabilizing active ingredients, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

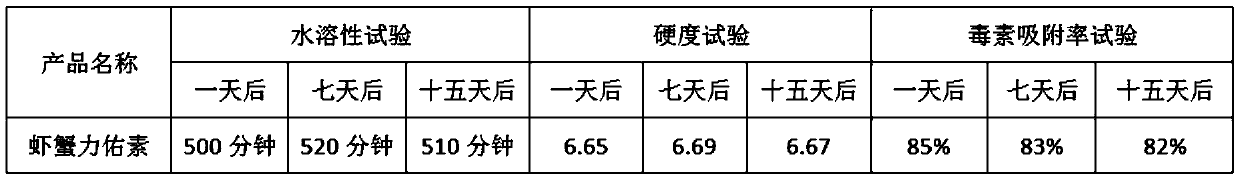

Examples

preparation example Construction

[0029] A method for preparing a feed quality improver for shrimp and crabs, comprising the following preparation steps: Step 1: the attapulgite is dried in the air or dried in a hot stove to reduce the water content to below 12, and enter the stirring process after passing the test;

[0030] Step 2: Add lignosulfonate, stabilizer, sodium aluminosilicate, cellulose and sorbitol hepatic fatty acid ester with a concentration of 3% to the dried attapulgite, and stir for 1-4 hours, so that After the attapulgite is fully acidified, it is press-filtered;

[0031] Step 3: Grinding the attapulgite after pressure filtration with rollers, drying at a high temperature of 85°C until the moisture content is below 10, and milling after passing the inspection;

[0032] Step 4: Filter the attapulgite powder after grinding, so that the number of attapulgite powder passing through the 200-mesh sieve is more than 95%, and then enter the step of checking the semi-finished product;

[0033] Step 5...

Embodiment 1

[0039] A method for preparing a feed quality improver for shrimp and crabs, comprising the following preparation steps: Step 1: 65 parts by mass of attapulgite is dried in the air or in a hot air stove to reduce the moisture content to below 12, and enter the stirring process after passing the test. process;

[0040] Step 2: Add 2 parts by mass of lignosulfonate, 1 part by mass of sodium alginate, 2 parts by mass of sodium aluminosilicate, 5 parts by mass of Sodium carboxymethyl cellulose and 1 mass part of sorbitol hepatic fatty acid ester were stirred for 1 hour, so that the attapulgite was completely acidified and then press-filtered;

[0041] Step 3: Grinding the attapulgite after pressure filtration with rollers, drying at a high temperature of 85°C until the moisture content is below 10, and milling after passing the inspection;

[0042] Step 4: Filter the attapulgite powder after grinding, so that the number of attapulgite powder passing through the 200-mesh sieve is m...

Embodiment 2

[0047] A method for preparing a feed quality improver for shrimp and crabs, comprising the following preparation steps: Step 1: 80 parts by mass of attapulgite is dried in the air or in a hot air stove to reduce the water content to below 12, and enter the stirring process after passing the test process;

[0048] Step 2: Add 4 parts by mass of lignosulfonate with a concentration of 3%, potassium alginate of 2 parts by mass, sodium aluminosilicate of 4 parts by mass, and 7 parts by mass of Polyacrylic resin II and 3 parts by mass of sorbitan hepatic fatty acid ester were stirred for 3 hours to make the attapulgite completely acidified and then press-filtered;

[0049] Step 3: Grinding the attapulgite after pressure filtration with rollers, drying at a high temperature of 85°C until the moisture content is below 10, and milling after passing the inspection;

[0050] Step 4: Filter the attapulgite powder after grinding, so that the number of attapulgite powder passing through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com