Method for preparing white carbon black and pure zeolite molecular sieve using flyash

A technology of zeolite molecular sieve and fly ash, which is applied in the direction of crystalline aluminosilicate zeolite, silicon oxide, etc., can solve the problems of low silicon-alumina dissolution rate, low utilization rate of fly ash and aluminum, low molecular sieve purity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

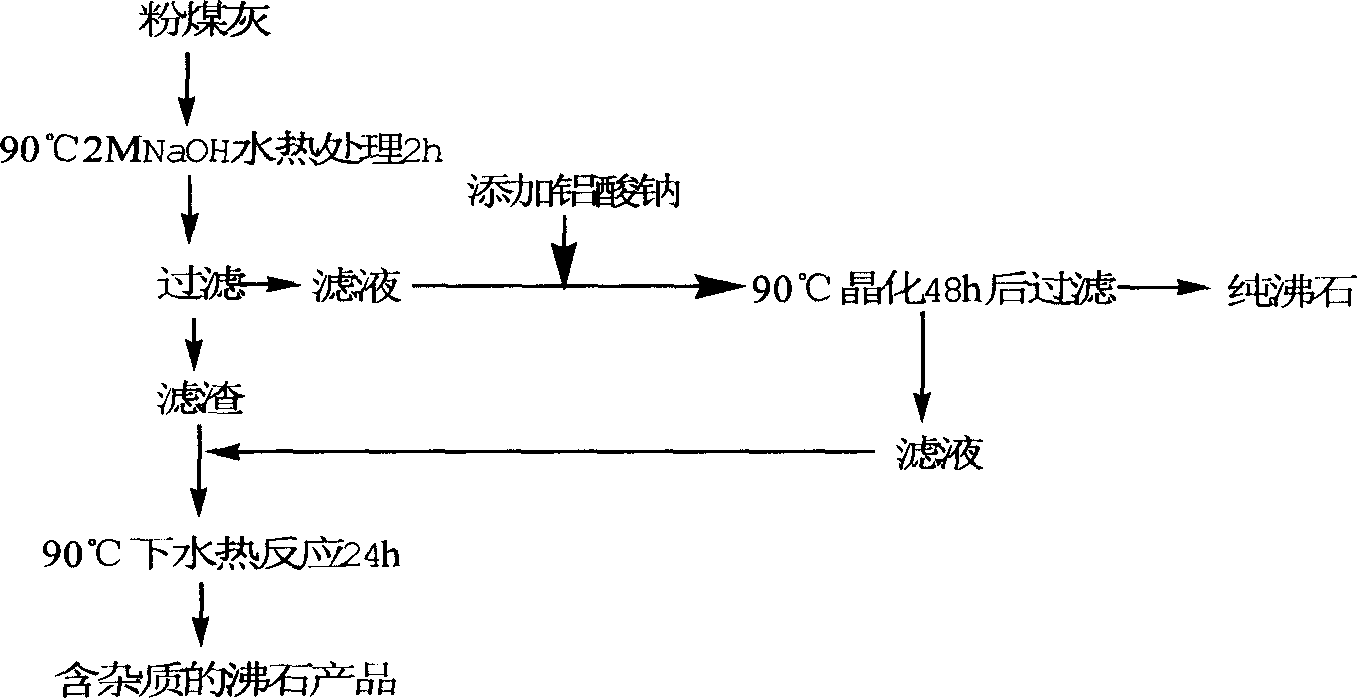

Method used

Image

Examples

Embodiment Construction

[0017] Select fly ash from a power plant and pass through a 200-mesh sieve. The main component of fly ash is SiO 2 and Al 2 o 3 , also contains iron, calcium, magnesium, potassium and other elements. Its chemical composition is analyzed by chemical capacity analysis and ICP-MAS analysis results are as follows:

[0018] chemical composition

SiO 2

al 2 o 3

Fe 2 o 3

CaO

MgO

K 2 o

SO 3

percentage%

54.0

28.5

2.75

0.58

0.21

0.37

0.59

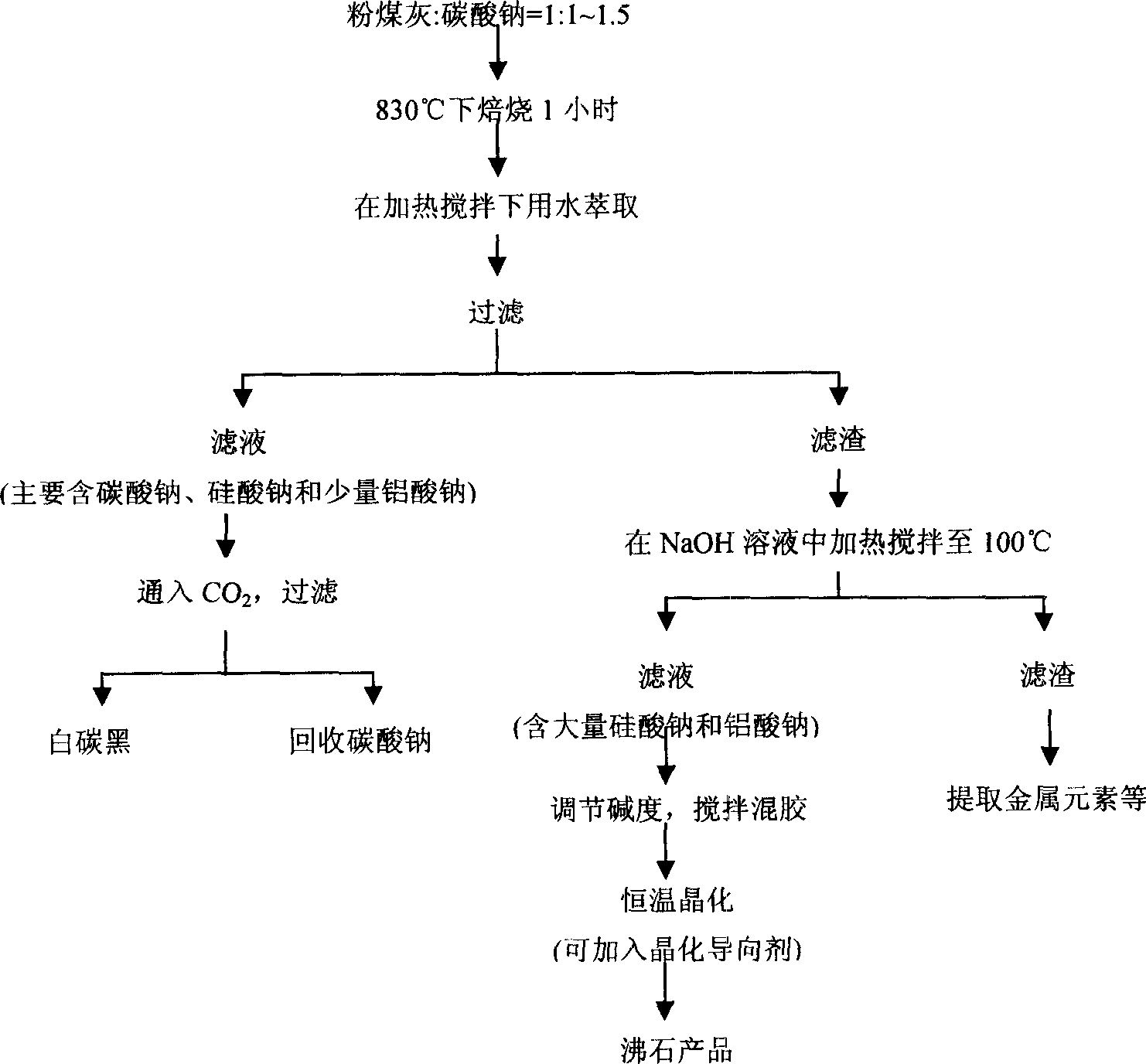

[0019] 1. Put the power plant fly ash and sodium carbonate in a kiln with a molar ratio of 1:1 and heat it to 830°C, keep it warm for 1 hour, and wait for cooling. Use water with a liquid-solid ratio of 5:1 to extract the roasted product, heat and stir, and obtain a sodium silicate solution after filtration, and pass CO into the sodium silicate solution 2 , to prepare white carbon black.

[0020] 2. Use 1.5mol / L NaOH solution to leach the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com