Preparation method and preparation device of choline chloride powder

A choline chloride water agent and choline chloride technology, which are applied in botany equipment and methods, biocides, animal repellants, etc., can solve the problems of long production cycle, affecting product quality, and high energy consumption for drying , to achieve the effect of increasing the price period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

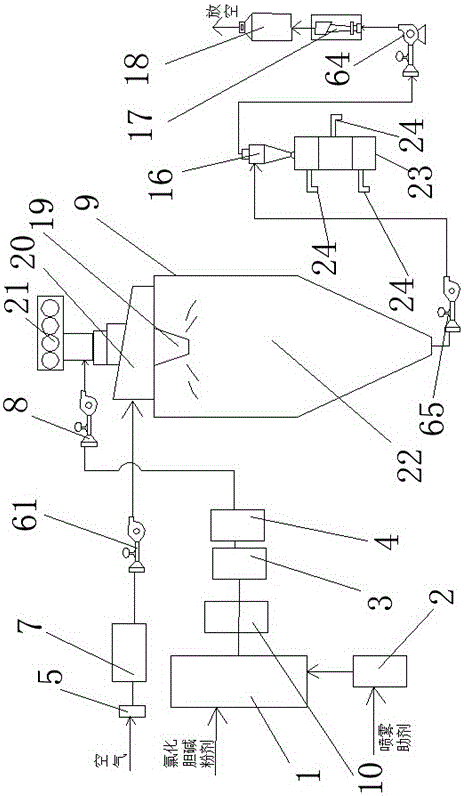

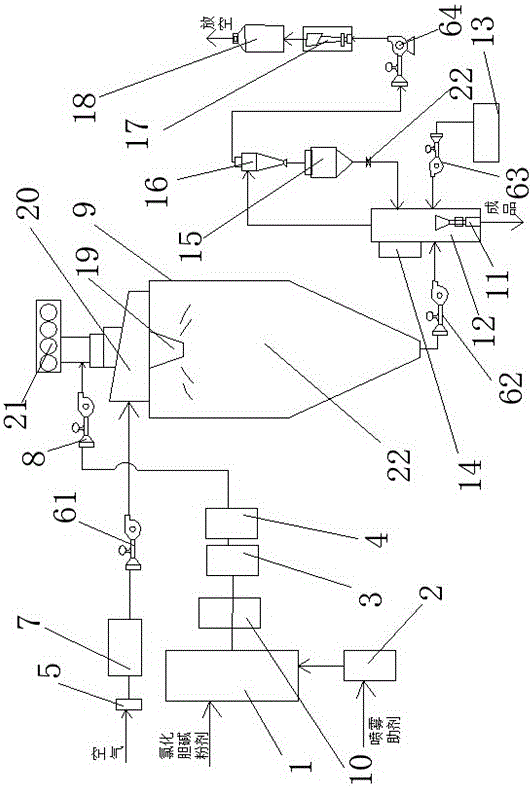

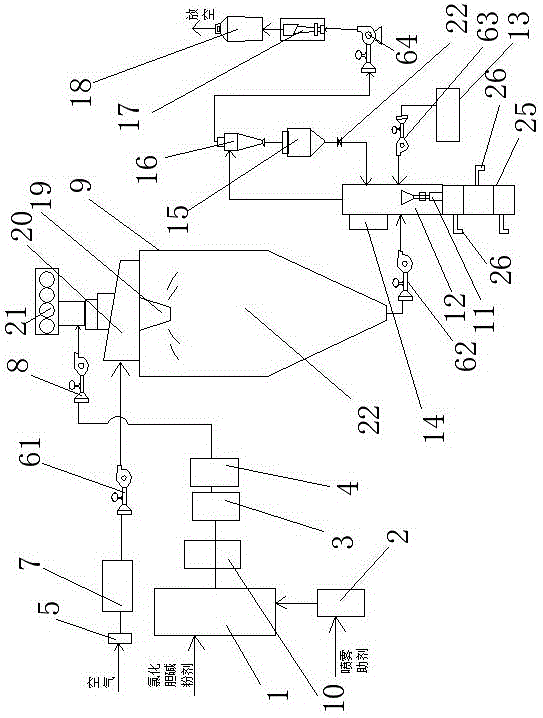

Method used

Image

Examples

Embodiment 1

[0069] Example 1. A preparation method for choline chloride powder, is characterized in that, comprises the steps:

[0070] Step 1: obtaining the choline chloride aqueous solution whose weight percentage of choline chloride is 50%;

[0071] Step 2: Adding a spray auxiliary agent to the choline chloride aqueous solution, the amount of the spray auxiliary agent added is 2 to 15% of the weight of the choline chloride aqueous solution, and mixing and stirring evenly;

[0072] Step 3: Pump the choline chloride water agent added with spray aid into the spray drying equipment for spray drying. The pressure of the nozzle is controlled at 3.5Mpa, the inlet air temperature is 210°C, and the outlet air temperature is 100°C, and the choline chloride is dried. powder;

[0073] Step 4: Send the choline chloride dry powder into a mixing tank, add potassium ferrocyanide whose weight is 3% of the choline chloride dry powder to the mixing tank, stir and mix to obtain the choline chloride powd...

Embodiment 2

[0076] Example 2. A preparation method for choline chloride powder, is characterized in that, comprises the steps:

[0077] Step 1: obtaining the choline chloride aqueous solution whose weight percent of choline chloride is 75%;

[0078] Step 2: Adding a spray auxiliary agent to the choline chloride aqueous solution, the amount of the spray auxiliary agent added is 2 to 15% of the weight of the choline chloride aqueous solution, and mixing and stirring evenly;

[0079] Step 3: Pump the choline chloride water agent added with spray aid into the spray drying equipment for spray drying. The nozzle pressure is controlled at 4Mpa, the air inlet temperature is 260°C, and the air outlet temperature is 120°C to obtain dry choline chloride powder ;

[0080] Step 4: send the choline chloride dry powder into the mixing tank, add 5% calcium stearate with a weight of 5% of the choline chloride dry powder to the mixing tank, stir and mix to obtain the choline chloride powder.

[0081] Th...

Embodiment 3

[0083] Example 3. A preparation method for choline chloride powder, is characterized in that, comprises the steps:

[0084] Step 1: obtaining a choline chloride aqueous solution with a weight percentage of 50% to 80% of choline chloride;

[0085] Step 2: Adding a spray auxiliary agent to the choline chloride aqueous solution, the amount of the spray auxiliary agent added is 2 to 15% of the weight of the choline chloride aqueous solution, and mixing and stirring evenly;

[0086] Step 3: Pump the choline chloride water agent added with spray aid into the spray drying equipment for spray drying. The pressure of the nozzle is controlled at 5.0Mpa, the inlet air temperature is 300°C, and the outlet air temperature is 150°C, and the choline chloride is dried. powder;

[0087] Step 4: Send the dry choline chloride powder into a mixing tank, add silicon dioxide whose weight is 30% of the dry choline chloride powder to the mixing tank, stir and mix to obtain the choline chloride powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com