Preparing method for titaniferous inorganic flocculant

An inorganic flocculant and flocculant technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of poor technical and economic indicators of titanium dioxide, unsatisfactory titanium-rich impurity removal effect, loss and utilization, etc., to save silicic acid Polymerization process, realize the utilization of waste water resources, and the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

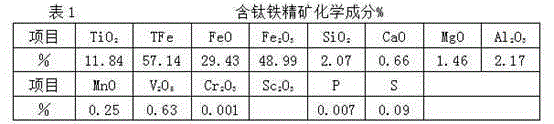

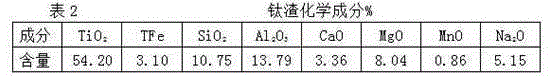

[0037] As a preferred embodiment of the present invention, it discloses a preparation method of titanium-containing inorganic flocculant, using vanadium-titanium magnetite as the basic raw material, adding sodium to the iron concentrate obtained by magnetic separation in electric furnace reduction smelting or potassium salt additives (such as sodium carbonate, sodium hydroxide, sodium oxide, potassium carbonate, potassium hydroxide, potassium oxide) to obtain molten iron and titanium-containing slag, in which: vanadium and iron are reduced into molten iron, and under the condition of smelting high temperature , silicon, aluminum impurities and sodium or potassium salt additives form sodium aluminosilicates soluble in dilute acid, and remain in titanium-containing slag with titanium and calcium-magnesium impurities; then, hydrometallurgical methods are used for titanium-containing slag Extract silicon, aluminum and iron from titanium-containing slag as raw materials for preparin...

Embodiment approach

[0039] As a preferred embodiment of the present invention, its specific steps are as follows:

[0040] a. Reduction smelting in electric furnace: mix iron concentrate with reducing agent coal and sodium or potassium salt additives, carry out reduction smelting in submerged arc furnace (or other direct reduction furnace), vanadium and iron are reduced into molten iron, and molten iron is oxidized and extracted by converter Vanadium separates iron and vanadium. Under the high temperature conditions of smelting, silicon and aluminum impurities that are difficult to reduce and sodium or potassium salt additives form dilute acid-soluble aluminosilicates and titanium, calcium and magnesium impurities remain in the titanium-containing slag:

[0041] ;

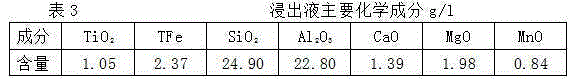

[0042] b. Acid leaching of titanium-containing slag: Under normal pressure, dilute sulfuric acid or dilute hydrochloric acid with H ion concentration of 2-3N is used for hydrometallurgical leaching of titanium-containing slag, and t...

Embodiment 3

[0048] On the basis of Example 1 or 2, in step a, the weight ratio among iron concentrate, reducing agent coal, sodium or potassium salt additive is: 74:16:10. In step b, the acid leaching of titanium-containing slag specifically refers to: grind the titanium slag to a particle size of -100 mesh accounting for 100%±, and use dilute hydrochloric acid to leach the titanium slag, wherein: the concentration of hydrochloric acid is 11%, the leaching liquid-solid ratio is 4, and stirring at room temperature Leach for 1 hour, and then carry out solid-liquid separation after the leaching ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com