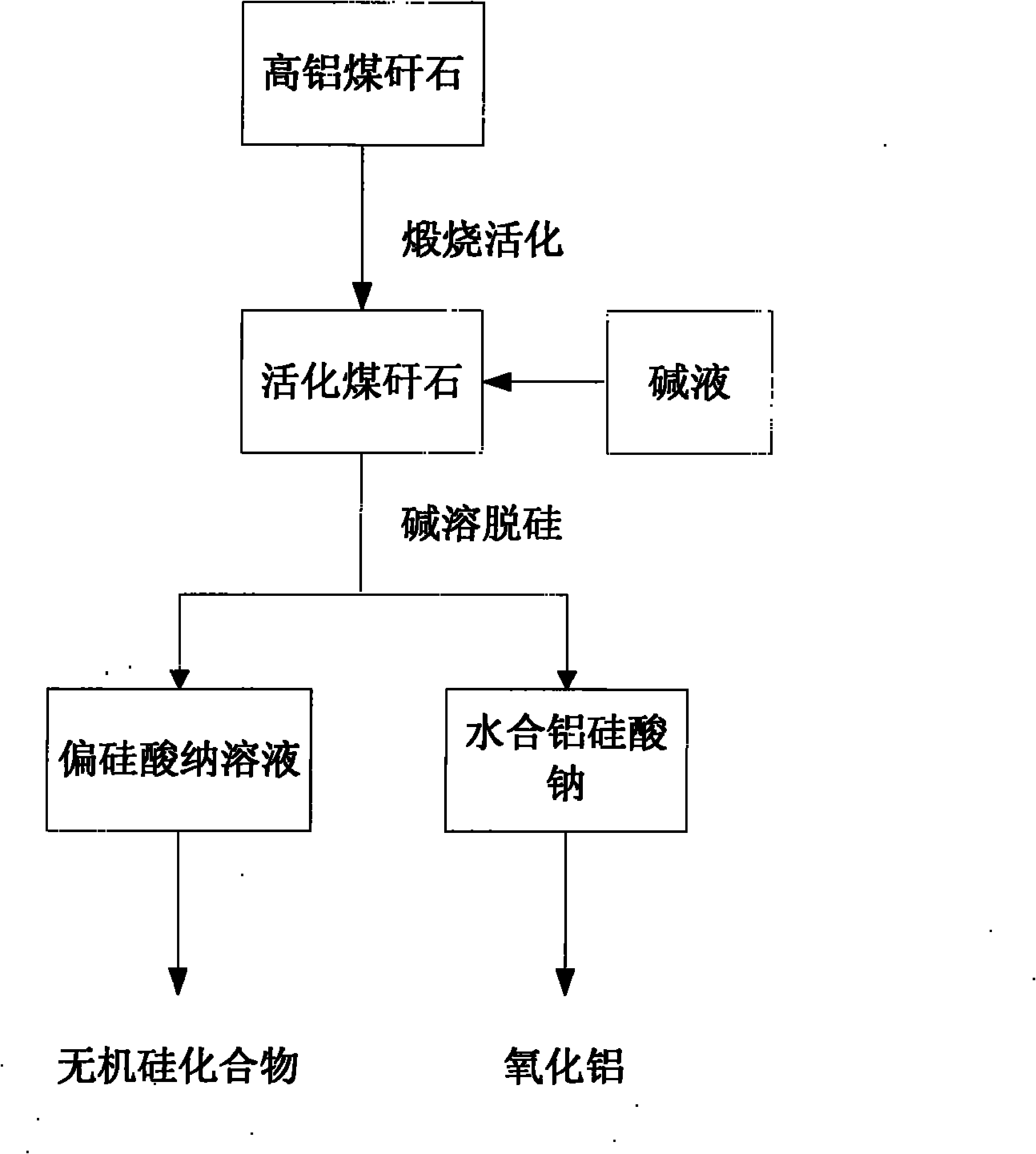

Technology for preparing hydrated sodium aluminosilicate by utilizing high-alumina coal gangue and fly ash alkali soluble desiliconization

A technology of hydrated sodium aluminosilicate and high-alumina coal gangue, which is applied in the field of extracting alumina from high-alumina fly ash and high-alumina coal gangue, can solve the problems of high production cost, difficult promotion, large sodium hydroxide, etc., and achieve improvement Technological and economic feasibility, improvement of economic benefits, and effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Experimental raw material: high-alumina coal gangue from a certain place

[0026] Table 1 Analysis results of chemical composition of high-alumina coal gangue samples (w B %)

[0027]

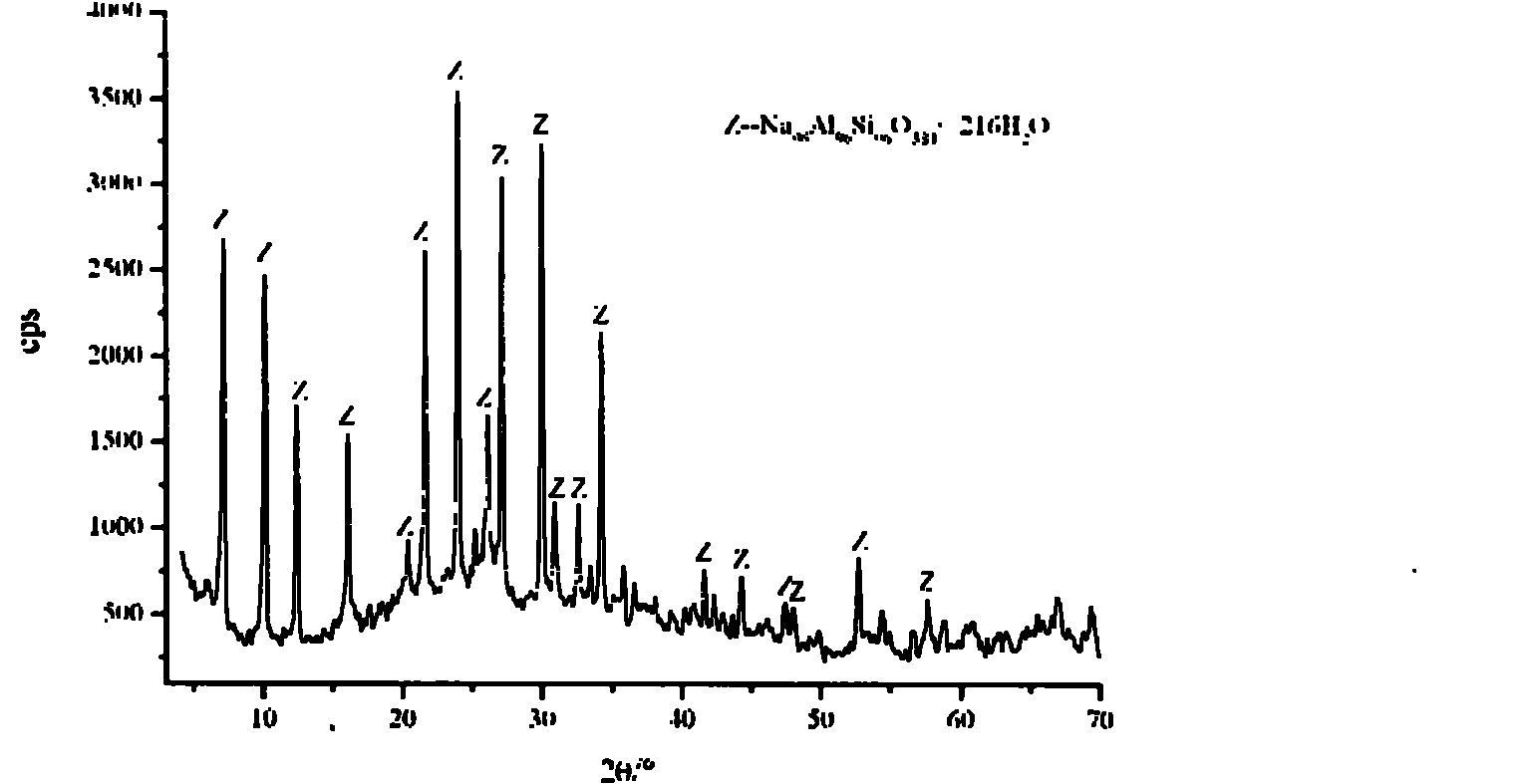

[0028] The above-mentioned high-alumina coal gangue samples were taken, placed in a box-type electric furnace, and calcined at 1000° C. for 3 hours, and the calcined products were ground to -325 mesh > 90%. Take 1000 g of calcined high-alumina coal gangue samples, 2 L of sodium hydroxide lye with a concentration of 4 mol / L, place them in the reactor and mix them evenly, open the instrument after sealing, and heat up to 95°C, keep stirring for 4 hours under this condition, filter after the reaction, and wash the filter cake with 2L of industrial water for 3 times to obtain 3.36L of sodium silicate filtrate (used to prepare inorganic silicon compounds). The chemical composition analysis results are shown in Table 2 Obtain hydrated sodium aluminosilicate material 990g, its X-ray powder...

Embodiment 2

[0035] Experimental raw material: high-alumina fly ash from a certain place

[0036] Table 4 Analysis results of chemical composition of high alumina fly ash samples (w B %)

[0037]

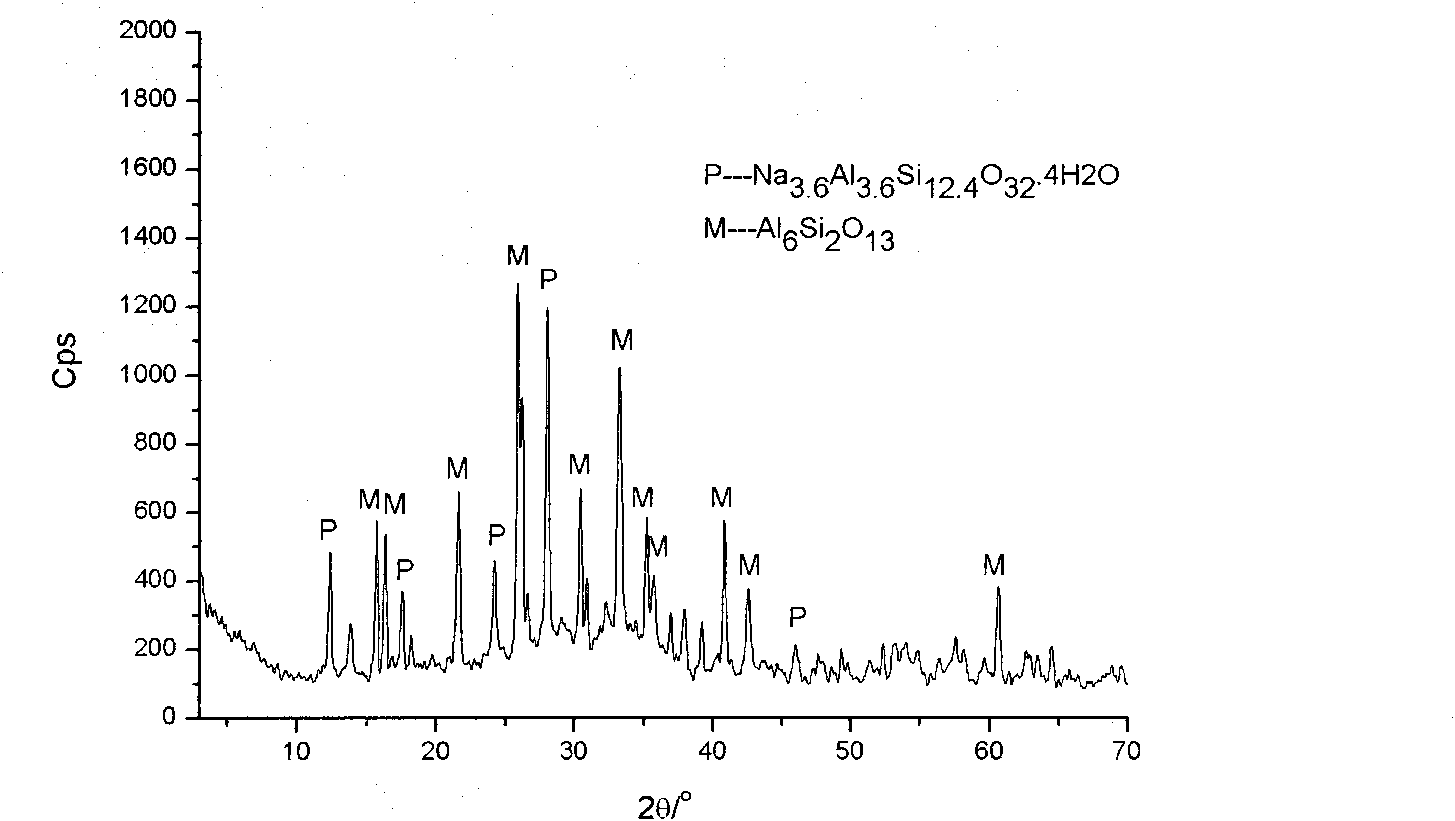

[0038] Grind the above-mentioned high-alumina coal gangue sample to -325 mesh > 90%, take 2000g of finely ground high-alumina fly ash and 4L of lye with a concentration of 6mol / L, put it in the reaction kettle and mix evenly, seal it and open the instrument. Under the condition of continuous stirring (150r / min), the temperature was raised to 100°C, and the stirring was continued for 3 hours under this condition. After the reaction was completed, it was filtered, and the filter cake was washed 3 times with 4L of industrial water to obtain 652L of sodium silicate filtrate (used to prepare inorganic silicon compound), its chemical composition analysis results are shown in Table 5; obtain 1800g of hydrated sodium aluminosilicate material, and its X-ray powder diffraction pattern is shown in im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com