Active admixture, preparation method and application for active admixture, and concrete

A concrete and active technology, which is applied in the field of building materials, can solve problems such as insufficient strength, high energy consumption for dehydration, and rapid loss of concrete performance, and achieve the effect of reducing production costs and improving hydration activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

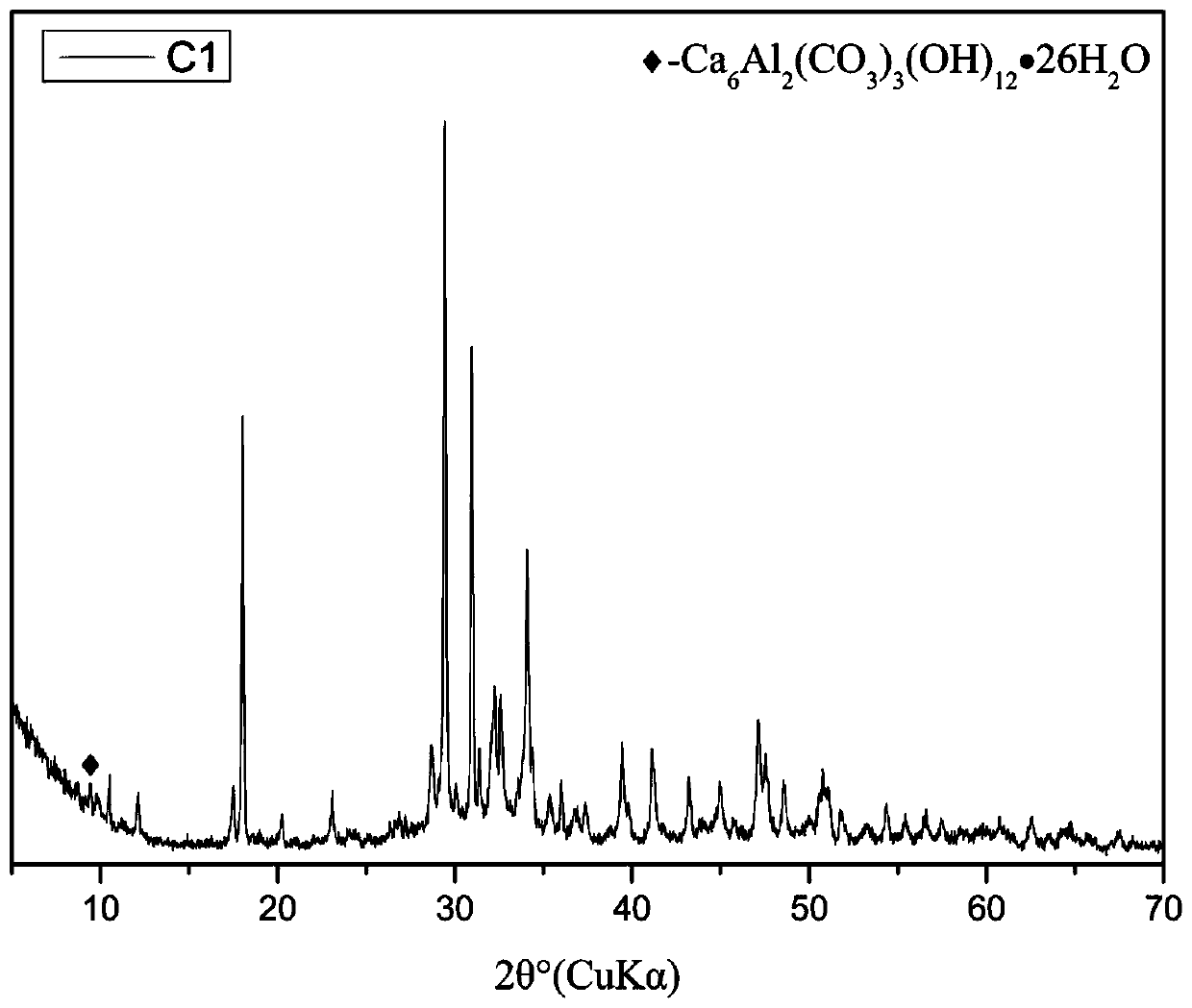

Image

Examples

Embodiment 1

[0027] This embodiment provides an active admixture and a preparation method thereof. Specifically, the preparation method of the active admixture includes the following steps:

[0028] (1) Weigh 1kg of Bayer process red mud, 0.5kg of quicklime powder and 8kg of limestone powder for subsequent use; wherein, the Bayer process red mud comes from Chinalco Shandong Co., Ltd., its water content is 15%, and the quality of its alumina The content of calcium oxide in limestone powder is 20%; the mass content of calcium oxide in quicklime powder is 90%, and the average fineness of quicklime powder is 300 mesh; the mass content of calcium oxide in limestone powder is 50%, and the average specific surface area of limestone powder is 400m 2 / kg.

[0029] (2) Stir and mix the above-mentioned Bayer red mud and quicklime powder to obtain a mixture; wherein, the calcium oxide in the quicklime powder will react with the water in the Bayer red mud and release a large amount of heat at the sam...

Embodiment 2

[0032] This embodiment provides an active admixture and a preparation method thereof. Specifically, the preparation method of the active admixture includes the following steps:

[0033] (1) Take by weighing 3kg of Bayer process red mud, 1.5kg of quicklime powder and 12kg of limestone powder for subsequent use; wherein, the Bayer process red mud comes from Chinalco Shandong Co., Ltd., its water content is 35%, and the quality of its alumina The content of calcium oxide in limestone powder is 40%; the mass content of calcium oxide in quicklime powder is 95%, and the average fineness of quicklime powder is 350 mesh; the mass content of calcium oxide in limestone powder is 60%, and the average specific surface area of limestone powder is 500m 2 / kg.

[0034] (2) Stir and mix the above-mentioned Bayer red mud and quicklime powder to obtain a mixture; wherein, the calcium oxide in the quicklime powder will react with the water in the Bayer red mud and release a large amount of hea...

Embodiment 3

[0037] This embodiment provides an active admixture and a preparation method thereof. Specifically, the preparation method of the active admixture includes the following steps:

[0038] (1) Take by weighing 1.5kg of Bayer process red mud, 0.8kg of quicklime powder and 9kg of limestone powder for subsequent use; wherein, the Bayer process red mud comes from Chinalco Shandong Co., Ltd., its water content is 20%, and its alumina The mass content is 25%; the mass content of calcium oxide in quicklime powder is 93%, and the average fineness of quicklime powder is 320 mesh; the mass content of calcium oxide in limestone powder is 55%, and the average specific surface area of limestone powder is 550m 2 / kg.

[0039] (2) Stir and mix the above-mentioned Bayer process red mud and quicklime powder to obtain a mixture; wherein, the calcium oxide in the quicklime powder reacts with the water in the Bayer process red mud and releases a large amount of heat at the same time, so that the B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average fineness | aaaaa | aaaaa |

| Average specific surface area | aaaaa | aaaaa |

| Average fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com