Mold material for injection molding of automobile bumper and preparation method of mold material

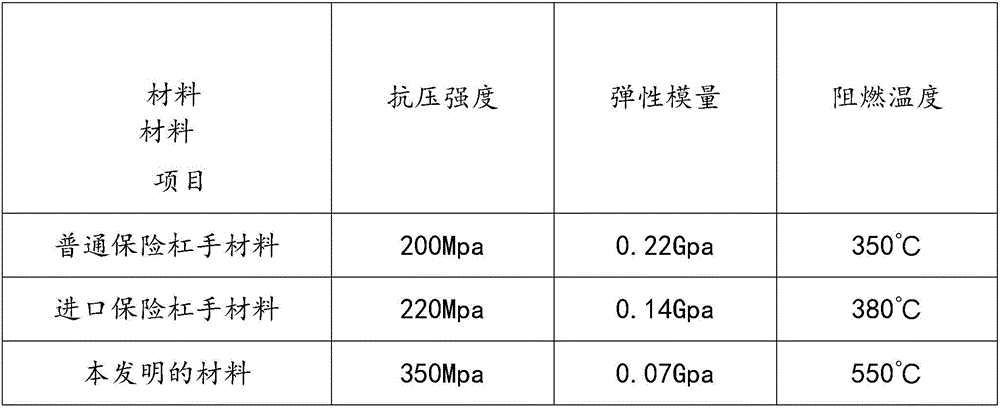

A technology for automobile bumper and injection molding, which is applied to the field of mold materials for automobile bumper injection molding and its preparation field, can solve the problems of weak structure, poor flame retardant effect, and no buffering effect of materials, and achieves flame retardant effect. Good, solid structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A mold material for injection molding of automobile bumper, which is made of the following materials in parts by weight, including 25 parts of polycarbonate, 35 parts of polyethylene terephthalate, 16 parts of polyurethane, polyacrylonitrile-based carbon fiber 7 parts, 5 parts of nano-alumina, 14 parts of silicon carbide, 3 parts of calcium stearate, 6 parts of pentaerythritol, 2 parts of trioctyl ester, 7 parts of molybdenum dioxide, 16 parts of montmorillonite, 12 parts of sodium aluminosilicate 3 parts of silicone rubber, 14 parts of polyvinyl acetate emulsion, 12 parts of titanium dioxide, 20 parts of titanate coupling agent, 12 parts of ethylene-vinyl acetate copolymer, 6 parts of glyceride and 4 parts of dibasic lead stearate .

[0019] A preparation method of a mold material for injection molding of an automobile bumper, comprising the following steps:

[0020] 1) 25 parts of polycarbonate, 35 parts of polyethylene terephthalate, 16 parts of polyurethane, 7 part...

Embodiment 2

[0026] A mold material for injection molding of automobile bumper, which is made of the following materials in parts by weight, including 27.5 parts of polycarbonate, 37.5 parts of polyethylene terephthalate, 18 parts of polyurethane, and polyacrylonitrile-based carbon fiber 9 parts, 7.5 parts of nano-alumina, 16 parts of silicon carbide, 5.5 parts of calcium stearate, 7.5 parts of pentaerythritol, 3.5 parts of trioctyl ester, 9 parts of molybdenum dioxide, 17 parts of montmorillonite, 13 parts of sodium aluminosilicate 5.5 parts of silicone rubber, 16 parts of polyvinyl acetate emulsion, 13.5 parts of titanium dioxide, 21 parts of titanate coupling agent, 13.5 parts of ethylene-vinyl acetate copolymer, 8 parts of glyceride and 5.5 parts of dibasic lead stearate .

[0027] A preparation method of a mold material for injection molding of an automobile bumper, comprising the following steps:

[0028] 1) 27.5 parts of polycarbonate, 37.5 parts of polyethylene terephthalate, 18 p...

Embodiment 3

[0034]A mold material for injection molding of automobile bumper, comprising 30 parts of polycarbonate, 40 parts of polyethylene terephthalate, 20 parts of polyurethane, 11 parts of polyacrylonitrile-based carbon fiber, 10 parts of nano-alumina, and 18 parts of silicon carbide 8 parts of calcium stearate, 9 parts of pentaerythritol, 5 parts of trioctyl ester, 11 parts of molybdenum dioxide, 18 parts of montmorillonite, 14 parts of sodium aluminosilicate, 8 parts of silicone rubber, 18 parts of polyvinyl acetate emulsion parts, 15 parts of titanium dioxide, 22 parts of titanate coupling agent, 15 parts of ethylene-vinyl acetate copolymer, 10 parts of glyceride and 7 parts of dibasic lead stearate.

[0035] A preparation method of a mold material for injection molding of an automobile bumper, comprising the following steps:

[0036] 1) 30 parts of polycarbonate, 40 parts of polyethylene terephthalate, 20 parts of polyurethane, 11 parts of polyacrylonitrile-based carbon fiber, 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com