Process for preparing sodium potassium silicate solution by predesiliconizing potassium-rich rock

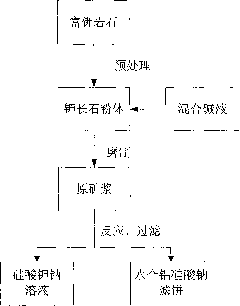

A technology of potassium sodium silicate and potassium-rich rock, which is applied in the direction of aluminum silicate, silicate, alkali metal silicate, etc., and can solve problems such as failure to realize industrial production, solid waste discharge, and impact on process economic benefits. To achieve the effect of increasing the ratio, reducing emissions, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Potassium-rich rock raw material 1: pseudoleucine syenite, the chemical composition is as follows (%):

[0031]

[0032] The phase composition of the pseudoleucine syenite is: potassium feldspar 66.1%; muscovite 24.3%; biotite 1.0%; melanite 6.5%; other accessory minerals 2.1%.

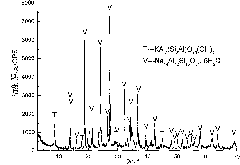

[0033] The pseudoleucine syenite ore is crushed and ground, and 5.0 kg of the obtained potassium feldspar powder and 20 L of NaOH solution with a concentration of 18% are ground in a ball mill to form a raw ore slurry with a fineness of -74 μm accounting for 90%; The prepared raw ore slurry was placed in a reaction kettle with a stirring rate of 200rpm, and the temperature was raised to 190°C for a constant temperature reaction for 4 hours; after the reaction was completed, the obtained reaction slurry was vacuum filtered (negative pressure 0.08MPa), and then 16L with a temperature of 85 The filter cake was washed four times with tap water at ℃ to obtain 8.10kg filter cake (water content 50%...

Embodiment 2

[0039] Potassium-rich rock raw material 2: quartz syenite, the chemical composition is as follows (%):

[0040]

[0041] The phase composition of the quartz syenite is: potassium feldspar 70.6%; quartz 18.3%; biotite 6.6%; other accessory minerals 4.5%.

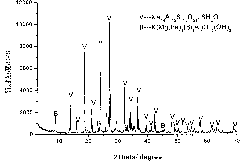

[0042] Quartz syenite ore is crushed and ground, and 7.0 kg of the obtained potassium feldspar powder and 20 L of alkali solution (NaOH / KOH (mass ratio) = 6.42) with a concentration of 25% are ground in a ball mill to make a fineness of -74 μm Accounting for 95% raw ore pulp; place the ground raw ore pulp in a reactor, stir at 200rpm, heat up to 200°C for constant temperature reaction for 2 hours; vacuum filter the obtained reaction slurry after the reaction (negative pressure 0.08 MPa), then wash the filter cake four times with 12L of 85°C tap water to obtain 7.84kg filter cake (water content 50%), dry it at 105°C for 4h, obtain the X-ray powder diffraction analysis results of 3.94kg dry filter cake See image 3 ,Depend...

Embodiment 3

[0048] Potassium-rich ore raw material 3: neon syenite, the chemical composition is as follows (%):

[0049]

[0050] The phase composition of the neonite syenite is: 91.4% microcline, 4.5% neonite, and 3.5% quartz.

[0051]Nihui syenite ore is crushed and ground, and the mixed lye (NaOH / KOH (mass ratio)=2.85) of 16% concentration of gained potassium feldspar powder 6.0kg and 22L is ground in a ball mill to make a fineness of -74 μm accounted for 90% raw ore pulp, put the ground raw ore pulp in the reactor, the stirring rate was 200rpm, and the temperature was raised to 230°C for constant temperature reaction for 3 hours, after the reaction, the obtained reaction slurry was vacuum filtered (negative pressure 0.08MPa), and then wash the filter cake four times with 15L of 85°C tap water to obtain 7.16kg of filter cake (water content 50%), and dry at 105°C for 4h to obtain 3.60kg of dry filter cake, its X-ray powder Diffraction analysis results see Figure 4 . The phase of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com