Composite lithium-calcium base lubricating grease and preparation method thereof

A technology of complex lithium-calcium and lubricating grease, which is applied in the chemical field, can solve the problems of unfavorable large-scale industrial production, great influence on colloidal stability, poor high temperature resistance, etc. Abrasion resistance, good mechanical stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

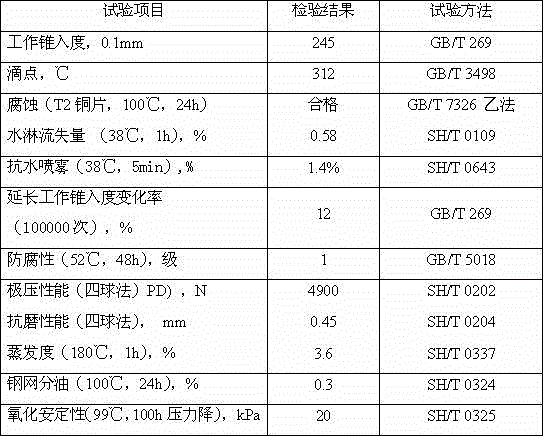

Embodiment 1

[0023] In this embodiment, the raw materials are prepared in the following manner for lithium-calcium base grease:

[0024] Step 1. Add 40°C viscosity of 120mm in a fat-making kettle with heating and stirring functions 2 / s,

[0025] 1618g of base oil 500SN and 321.6g of 12-hydroxystearic acid were mixed and stirred and heated to 85°C to completely dissolve the 12-hydroxystearic acid;

[0026] Step 2. Add 24.9g of calcium hydroxide and 23.7g of lithium hydroxide monohydrate mixture dissolved in water with 3 times the amount of alkali, saponify at 85°C for 40min, continue to heat up to 95°C, add 86.7g of sebacic acid, Then add 240ml of an aqueous solution containing 47.4g of lithium hydroxide monohydrate to react for 60min, then raise the temperature to 215°C for high-temperature refining;

[0027] Step 3: Add 659g of base oil 500SN, lower the temperature to 175°C and keep it warm for 15 minutes. When the temperature drops to 85°C, add 15g of diphenylamine, 45g of thionyl...

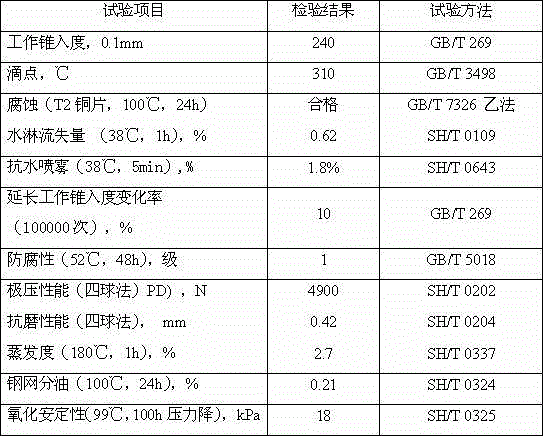

Embodiment 2

[0031] Step 1. Add 40°C viscosity of 220mm in a fat-making kettle with heating and stirring functions 2 / s,

[0032] 1833g of reduced second-line base oil, 330g of 12-hydroxystearic acid and 62.48g of stearic acid, mixed and stirred and heated to 85°C to completely dissolve the 12-hydroxystearic acid and stearic acid;

[0033] Step 2. Add 40.2g of calcium hydroxide and 22.2g of lithium hydroxide monohydrate mixture dissolved in water with 3 times the amount of alkali, saponify at 80°C for 45min, continue to heat up to 100°C, add 106.5g of sebacic acid, Then add 200ml of an aqueous solution containing 44.4g of lithium hydroxide monohydrate to react for 75min, then raise the temperature to 225°C for high-temperature refining;

[0034] Step 3: Add 319g of second-line base oil, lower the temperature to 180°C and keep it warm for 20 minutes. When the temperature drops to 80°C, add 9g of N-phenyl-α-naphthylamine and 60g of phosphobisoctyl basic zinc Salt, the potassium triborate o...

Embodiment 3

[0038] Step 1. Add 40°C viscosity of 480mm in a fat-making kettle with heating and stirring functions 2 / s,

[0039] 1572g of base oil 150BS and 240.9g of 12-hydroxystearic acid were mixed and stirred and heated to 85°C to completely dissolve the 12-hydroxystearic acid;

[0040] Step 2. Add 13.8g of calcium hydroxide and 21g of lithium hydroxide monohydrate mixture dissolved in water with 3 times the amount of alkali, saponify at 85°C for 60min, continue to heat up to 100°C, add 75.5g of azelaic acid, and then Add 250ml of an aqueous solution containing 42g of lithium hydroxide monohydrate to react for 60min, then raise the temperature to 220°C for high-temperature refining;

[0041] Step 3: Add 786g of base oil 150BS, lower the temperature to 170°C and keep it warm for 30 minutes. When the temperature drops to 85°C, add 12g of diphenylamine, 75g of thionyl octyl zinc salt, 25g of potassium triborate, 50g of Thioaminoester, 6g of 2-mercaptobenzothiadiazole, 30g of nanoscale ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com