Lithium-calcium complex lubricating grease composition and preparation method

A technology of complex calcium lubricating grease and composition, which is applied in the field of lubricating grease to achieve good mechanical stability and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

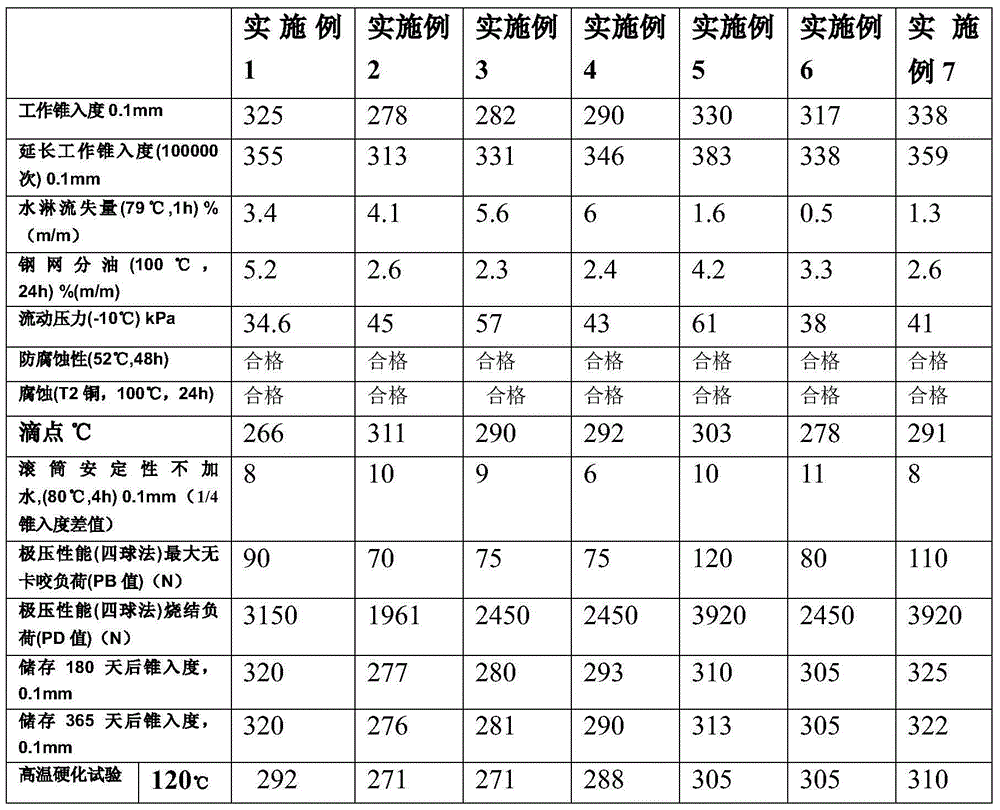

Examples

Embodiment 1

[0024] Put 2200KG of 650SN base oil into the reaction kettle, add 170KG of lauryl hydroxystearic acid, heat to 90°C, add 31KG of lithium hydroxide (dissolved in hot water) after the material is fully dissolved, and react at a constant temperature of 95°C for 40 minutes; after the reaction is completed Add 70KG of calcium hydroxide, keep the temperature at 110-115°C and slowly add glacial acetic acid 85KG (99%) dropwise after stirring evenly. After the dropwise addition is completed, react at a constant temperature of 115°C for 60 minutes. After the reaction is completed, the temperature is raised, and the maximum temperature is controlled at 200-210°C , the maximum temperature is constant for 30Min, and after the constant temperature is completed, 1000KG of 650SN base oil is used for cooling in the reactor. After cooling, the temperature is controlled above 170°C, and the temperature is naturally lowered. 3KG, sulfurized isobutylene: 25KG. When the temperature is lowered to 40...

Embodiment 2

[0026] Add 1000KG of 650SN and 1000KG of 150BS base oil into the reactor, add 300g of dodecyl hydroxystearic acid, heat to 90°C, add 43.2KG of lithium hydroxide (dissolved in hot water) after the materials are fully dissolved, and react at a constant temperature of 95°C for 40 minutes; After the reaction was completed, 660KG (99%) of glacial acetic acid and 500KG of calcium hydroxide were added, and the reaction was carried out at a constant temperature of 105°C for 120 minutes; the temperature was raised after the reaction was completed. The maximum temperature is controlled at 200-210°C, and the maximum temperature is constant for 30Min; after the constant temperature is completed, use 300KG of 650SN base oil and 300KG of 150BS base oil to cool in the reactor. ℃ Add T501: 50KG, T705: 35KG, T706: 6KG. When the temperature is lowered to 40-60°C, it will be packed in cans after being oil-pressed three times by a three-roller machine.

Embodiment 3

[0028] Add 1000KG of 650SN and 1000KG of 150BS base oil into the reactor, add 300g of dodecyl hydroxystearic acid, heat to 90°C, add 43.2KG of lithium hydroxide (dissolved in hot water) after the materials are fully dissolved, and react at a constant temperature of 95°C for 40 minutes; After the reaction, add 760KG of salicylic acid and 250KG of calcium hydroxide, and react at a constant temperature of 100°C for 120 minutes. After the reaction, the temperature rises. The maximum temperature is controlled at 200-210°C. After cooling, the temperature is controlled above 170°C, and the temperature is naturally lowered to 60-90°C, adding T501: 120KG, T705: 200KG, T706: 140KG. When the temperature is lowered to 40-60°C, it will be packed in cans after being oil-pressed three times by a three-roller machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com