Preparation method of polyurea-composite calcium lubricating grease

A technology of lubricating grease and polyurea, which is applied in the field of lubricating grease preparation, can solve the problems of volatilization of low-molecular acid, rising to 70-80°C, swelling of the pot, etc., achieving excellent high-temperature performance, easy operation, and avoiding volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

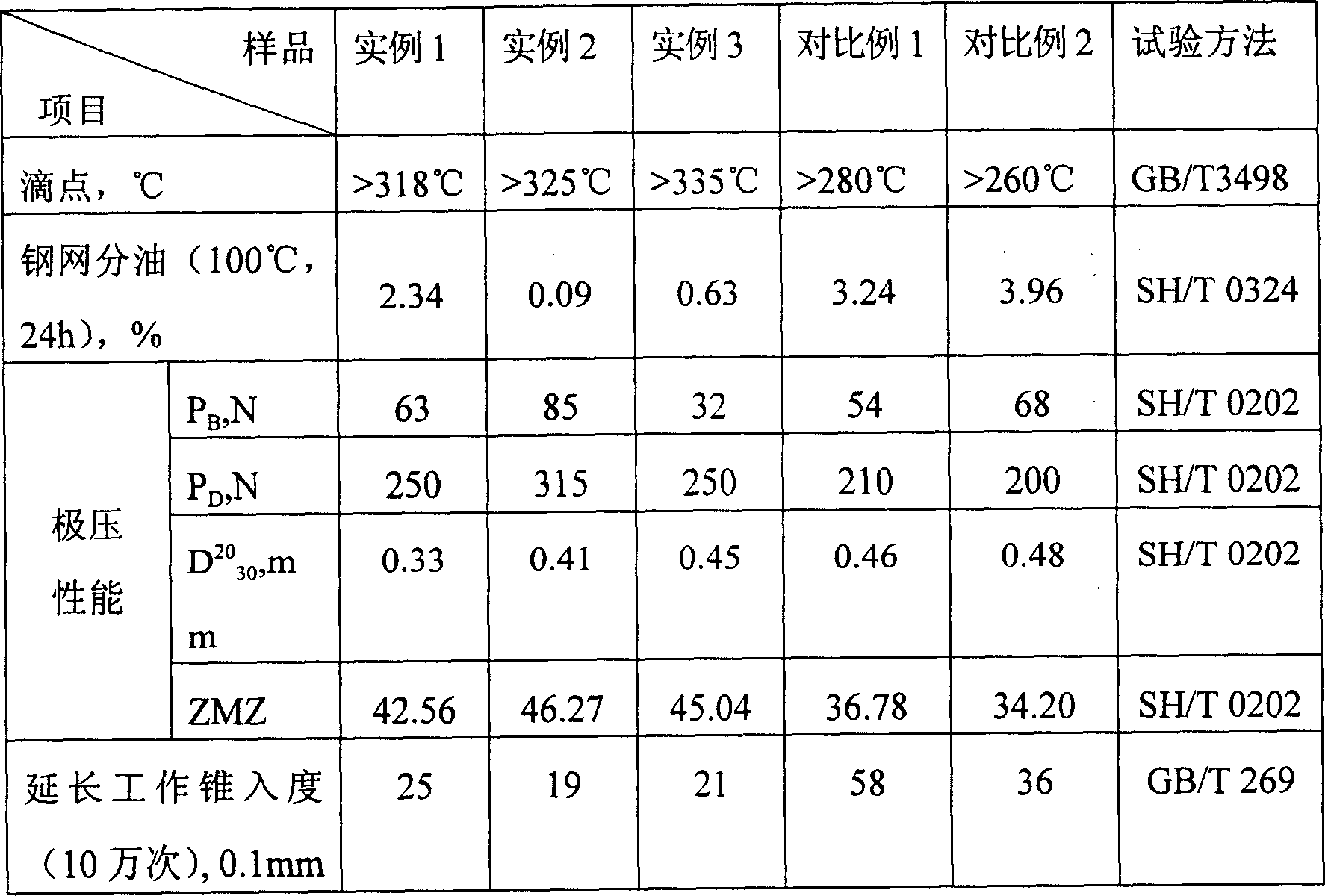

Embodiment 1

[0014] Put 800g of 500SN oil (40°C viscosity, 100°C viscosity 11mm 2 / s) 94.5g of calcium hydroxide and 450g of water were added to the normal pressure grease kettle, stirred evenly, and 117.9g of glacial acetic acid was added at room temperature, stirred evenly, and reacted for about 10 minutes, 28.3g of n-octanoic acid was added, stirred evenly, and ten Dihydroxystearic acid 117.8g, heating up to about 70 ℃. At the same time, add 80.7g of 4,4'-diphenylmethane diisocyanate (MDI) and 350g of 500SN oil into container A, and heat until the MDI is completely dissolved. Pour the MDI oil solution in container A into the fat-making kettle, and heat up to about 80°C. Then add 119.4g of dodecylamine, after 2 hours of saponification of drained water, continue to heat up to 220°C, add 200g of quenching oil, stir to lower the temperature, and grind at room temperature to obtain polyurea-composite calcium-based grease. The properties are shown in Table 1.

Embodiment 2

[0016] 350g hydrogenated α-olefin oil (viscosity 12mm at 100°C 2 / s) and 42g of calcium hydroxide and 200g of water were added to an ordinary pressure grease kettle, stirred evenly, added 49g of glacial acetic acid at room temperature, stirred evenly, and reacted for about 10 minutes, added 9.8g of boric acid, stirred evenly, and added dodecyl hydroxy Stearic acid 49g, heating up to about 70 ℃. At the same time, add 28 g of 2,4-tolyl diisocyanate (TDI) and 150 g of base oil into container A, and heat until the MDI is completely dissolved. Pour the MDI oil solution in container A into the fat-making kettle, and heat up to about 80°C. Then add 59.7g of dodecylamine, after 2 hours of draining saponification, continue to heat up to 220°C, add 100g of quenching oil, stir to lower the temperature, and grind at room temperature to obtain polyurea-complex calcium base grease. The properties are shown in Table 1.

Embodiment 3

[0018] 450g pentaerythritol ester (100 ℃ viscosity 12mm 2 / s) and 42g of calcium hydroxide and 200g of water were added to the normal pressure grease kettle, stirred evenly, and 49g of glacial acetic acid was added at room temperature, stirred evenly, and reacted for about 10 minutes, added 12g of n-octanoic acid, stirred evenly, and added dodecyl hydroxy Stearic acid 49g, heating up to about 70 ℃. At the same time, add 42g of 4,4'-diphenylmethane diisocyanate (MDI) and 150g of base oil into container A, and heat until the MDI is completely dissolved. Pour the MDI oil solution in container A into the fat-making kettle, and heat up to about 80°C. After that, add 90g of octadecylamine, drain the water and saponify for 2 hours, continue to heat up to 220°C, add 70g of quenching oil, stir to cool down, and grind at room temperature to obtain polyurea-composite calcium-based grease. The properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com