Synthetic high-temperature lubricating grease and preparation method thereof

A lubricating grease and high-temperature technology, which is applied in the field of synthetic high-temperature lubricating grease and its preparation, can solve problems such as structural damage, increased labor intensity of workers, and increased equipment wear, and achieve excellent corrosion resistance and rust resistance, excellent extreme pressure Anti-wear property, effect of improving lubrication condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

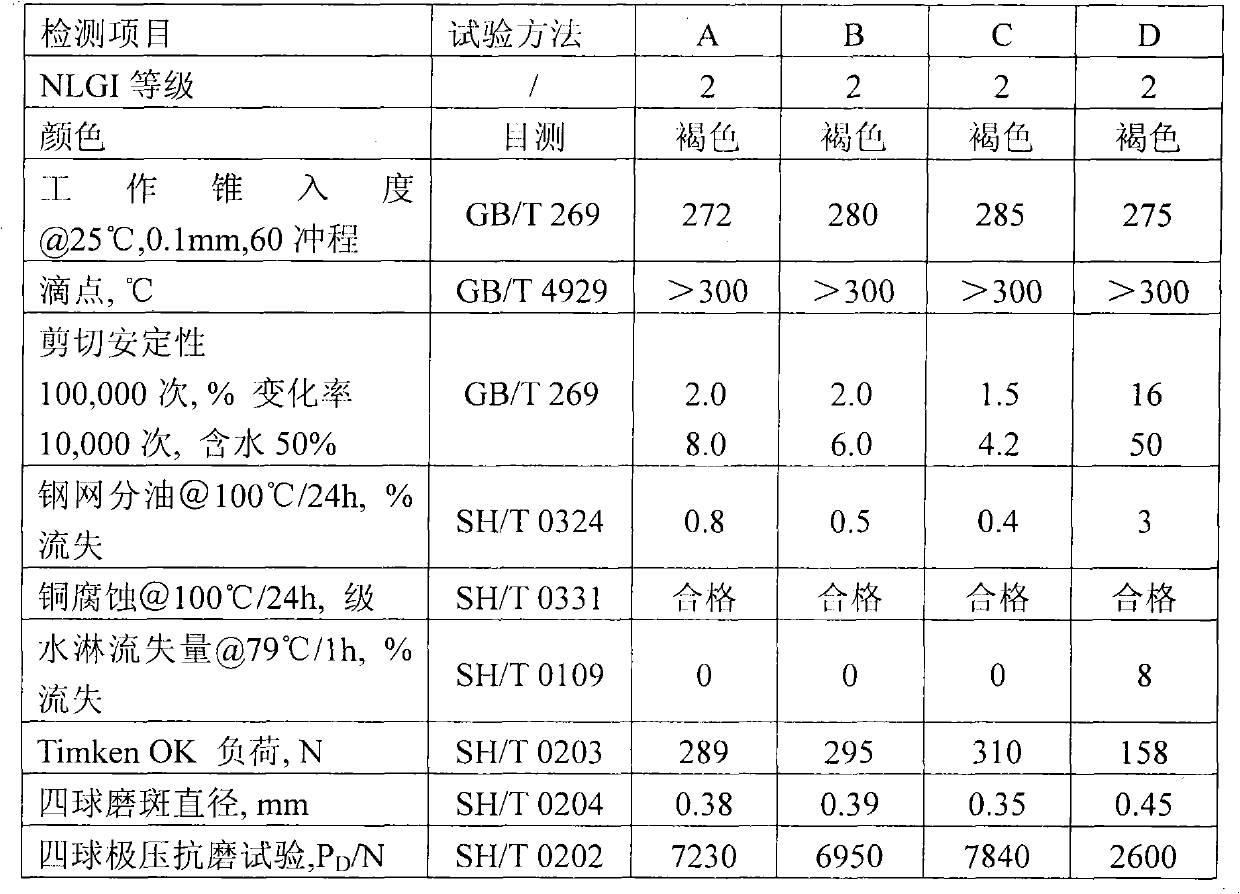

Examples

Embodiment 1

[0026] Synthetic high-temperature lubricating grease, its components and mass fractions: PAO base oil, viscosity at 100°C at 83.5cSt, 60%; high-alkaline calcium petroleum sulfonate 23%; 12-hydroxystearic acid 8%; boric acid 0.6%; Acetic acid 0.4%; water 3%; calcium hydroxide 4%; phenyl-α-aniline 1%.

[0027] Add base oil and high alkalinity petroleum calcium sulfonate into the reaction kettle, stir and heat up to 70°C, add acetic acid and water, stir evenly, raise the temperature to 110°C and keep for 30 minutes, after the material is thickened, add calcium hydroxide, Saponification reaction of 12-hydroxystearic acid and boric acid for 30 minutes; heat up to 150°C and keep, dehydration for 20 minutes; heat up to 220°C for high-temperature compound refining for 10 minutes; cool down to 100°C and add phenyl-α-aniline, Product A is produced after homogenization, degassing and filtration.

Embodiment 2

[0029] Synthetic high-temperature lubricating grease, its components and mass fractions: PAO base oil, viscosity at 100°C at 115cSt, 72%; high-alkali calcium petroleum sulfonate 18%; 12-hydroxystearic acid 4%; boric acid 2%; acetic acid 0.5%; water 1%; calcium hydroxide 2%; di-tert-butyl-p-cresol 0.5%.

[0030] Add base oil and high alkalinity petroleum calcium sulfonate into the reaction kettle, stir and heat up to 80°C, add acetic acid and water, stir evenly, raise the temperature to 100°C and keep for 50 minutes, after the material thickens, add calcium hydroxide, 12-Hydroxystearic acid and boric acid were saponified for 40 minutes; heated to 120°C and maintained for 30 minutes; heated to 200°C for high-temperature compound refining for 30 minutes; cooled to 100°C and added di-tert-butyl p-cresol, Product B is produced after homogenization, degassing and filtration.

Embodiment 3

[0032] Synthetic high-temperature lubricating grease, its components and mass fraction: PAO base oil, viscosity at 100°C at 112cSt, 32%; trimethylolpropane oleate, viscosity at 100°C at 460cSt, 22%; high alkali value petroleum sulfonic acid Calcium 30%; 12-Hydroxystearic Acid 8%; Boric Acid 1%; Acetic Acid 0.8%; Water 2%; Calcium Hydroxide 3%; %.

[0033] Add base oil and high alkalinity petroleum calcium sulfonate into the reaction kettle, stir and heat up to 70°C, add acetic acid and water, stir evenly, raise the temperature to 110°C and keep for 40 minutes, after the material is thickened, add calcium hydroxide, Saponification reaction of 12-hydroxystearic acid and boric acid for 60 minutes; heating up to 140°C and maintaining, dehydration for 50 minutes; heating up to 220°C for high-temperature compound refining for 30 minutes; cooling down to 100°C and adding di-tert-butyl p-cresol and Dialkyl zinc dithiophosphate, after homogenization, degassing and filtration, product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com