Compound sulphonic acid albany grease and method for producing the same

A composite calcium sulfonate-based grease and technology of composite calcium sulfonate, applied in the direction of lubricating compositions, etc., can solve the problem of excessive raw materials in the phase inversion process, affecting the overall quality of the composite calcium sulfonate-based grease, unstable phase inversion effect, etc. Problems, to achieve the effect of excellent pumping performance, excellent water resistance performance, and excellent water shear stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

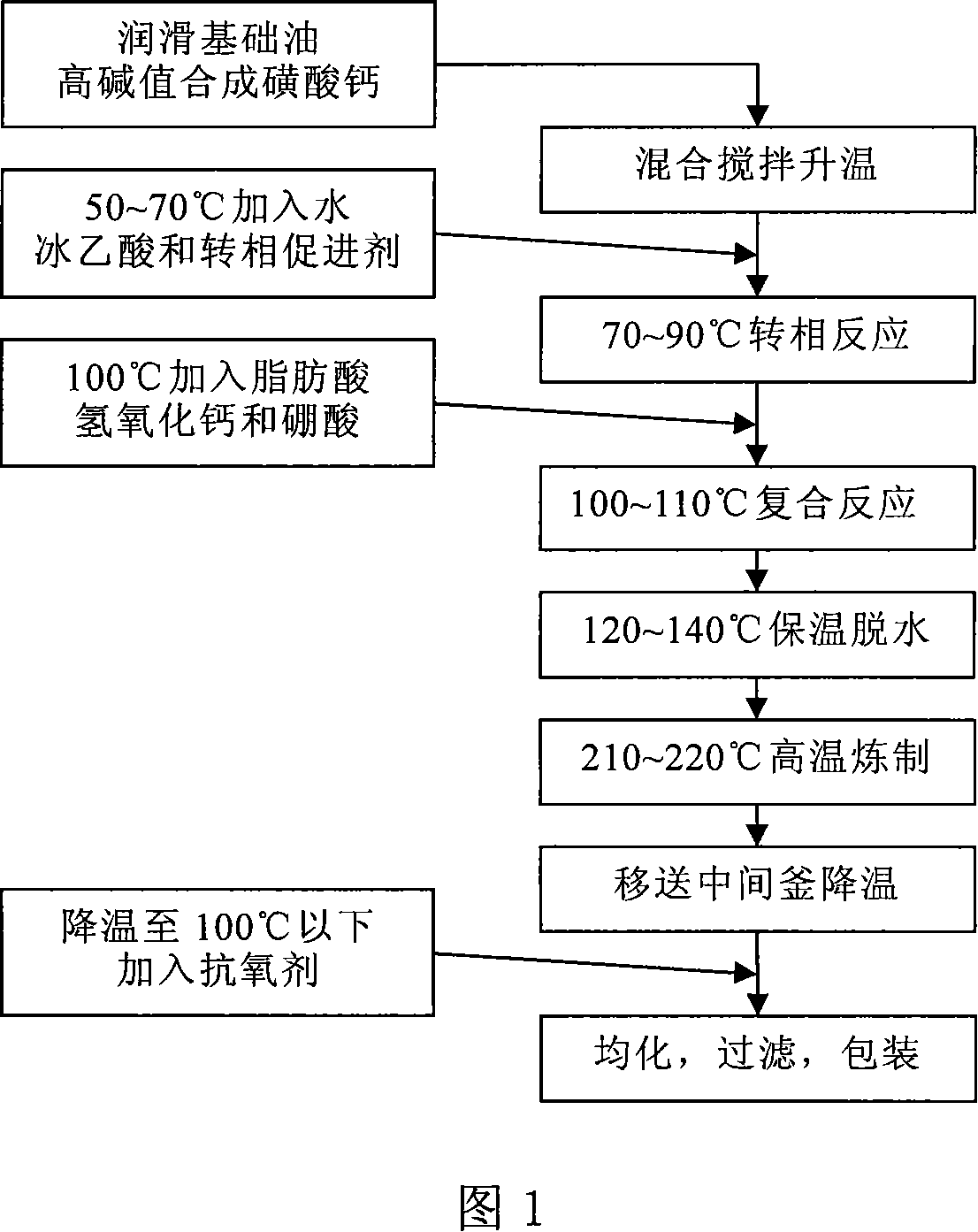

[0021] The production method of composite calcium sulfonate base lubricating grease of the present invention adopts following processing steps: its component ratio is by weight percentage:

[0022] The present invention takes paraffin-based mineral oil: 150BS 42%, ultra-high base value synthetic calcium sulfonate: 35%, phase inversion accelerator: calcium carbonate 2%, isopropanol 2%, dodecylbenzenesulfonic acid 3%, Glacial acetic acid: 0.8%, water: 5%, calcium hydroxide: 5%, lauryl hydroxystearic acid: 4%, boric acid: 0.9% and dialkyl diphenylamine 0.3% are composite calcium sulfonate base lubricating grease of the present invention components.

[0023] Test conditions: self-made small test saponification kettle, open, oil bath heating, volume 8L, normal pressure, speed 60 rpm. Take paraffin-based mineral oil: 150BS and synthetic calcium sulfonate with high alkalinity and add them into an open reactor, stir and mix well, heat up to 70°C and add phase inversion accelerators: ...

Embodiment 2

[0025] The production method of composite calcium sulfonate base lubricating grease of the present invention adopts following processing steps: its component ratio is by weight percentage:

[0026] The present invention takes paraffin-based mineral oil: 150BS 47%, high base value synthetic calcium sulfonate: 33.5%, phase inversion accelerator: calcium carbonate 2%, alkylbenzenesulfonic acid 4%, glacial acetic acid: 0.8%, water: 5% %, calcium hydroxide: 4%, stearic acid: 3%, boric acid: 0.6% and di-tert-butyl-p-cresol: 0.1% are the components of the complex calcium sulfonate base grease of the present invention.

[0027] Test conditions: self-made small test saponification kettle, open, oil bath heating, volume 8L, normal pressure, speed 60 rpm. Add high base value synthetic calcium sulfonate with a base value of 415mgKOH / g to 150BS paraffin-based mineral oil, heat up to 53°C, add calcium carbonate, dodecylbenzenesulfonic acid, glacial acetic acid and water in sequence, and kee...

Embodiment 3

[0029] The production method of composite calcium sulfonate base lubricating grease of the present invention adopts following processing steps: its component ratio is by weight percentage:

[0030] The present invention takes paraffin-based mineral oil: 150BS 26%, polyalphaolefin oil: PAO-8 26%, high alkali value synthetic calcium sulfonate: 32%, phase inversion accelerator: isopropanol 2.5%, alkylbenzene sulfonic acid 3%, glacial acetic acid: 0.6%, water: 4%, calcium hydroxide: 3.3%, lauryl hydroxystearic acid: 2%, boric acid: 0.5%, dialkyl diphenylamine: 0.1% are the compound sulfonic acid of the present invention Component of calcium-based grease.

[0031] Test conditions: self-made small test saponification kettle, open, oil bath heating, volume 8L, normal pressure, speed 60 rpm. Mix synthetic calcium sulfonate with a high base value of 413mgKOH / g, 150BS paraffin-based mineral oil and PAO-8 polyalphaolefin oil, and heat while stirring until the temperature rises to 65°C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com