Hub bearing lubricating grease and preparation method thereof

A wheel hub bearing and lubricating grease technology, which is applied in the field of hub bearing lubricating grease and its preparation, can solve the problems of poor anti-wear and anti-extreme pressure performance of lubricating grease, small applicable temperature range of lubricating grease, and easy oxidation loss of lubricating grease, etc. Good pressure and wear resistance, simple and feasible production process, excellent waterproof and anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

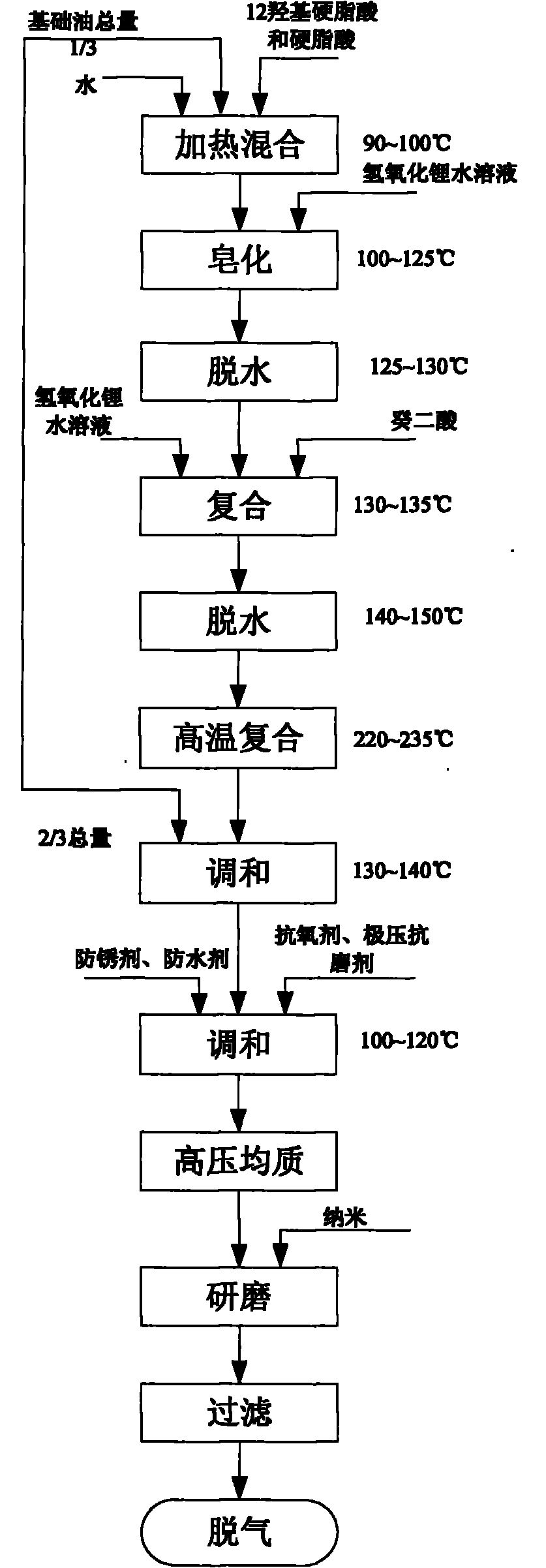

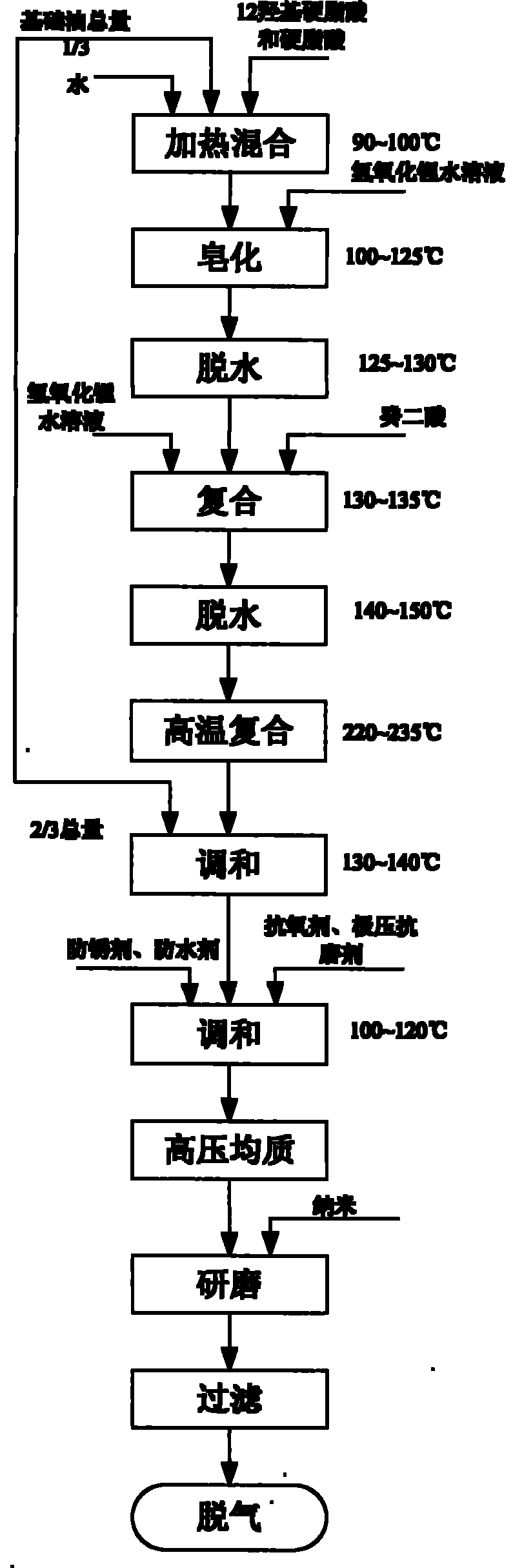

Method used

Image

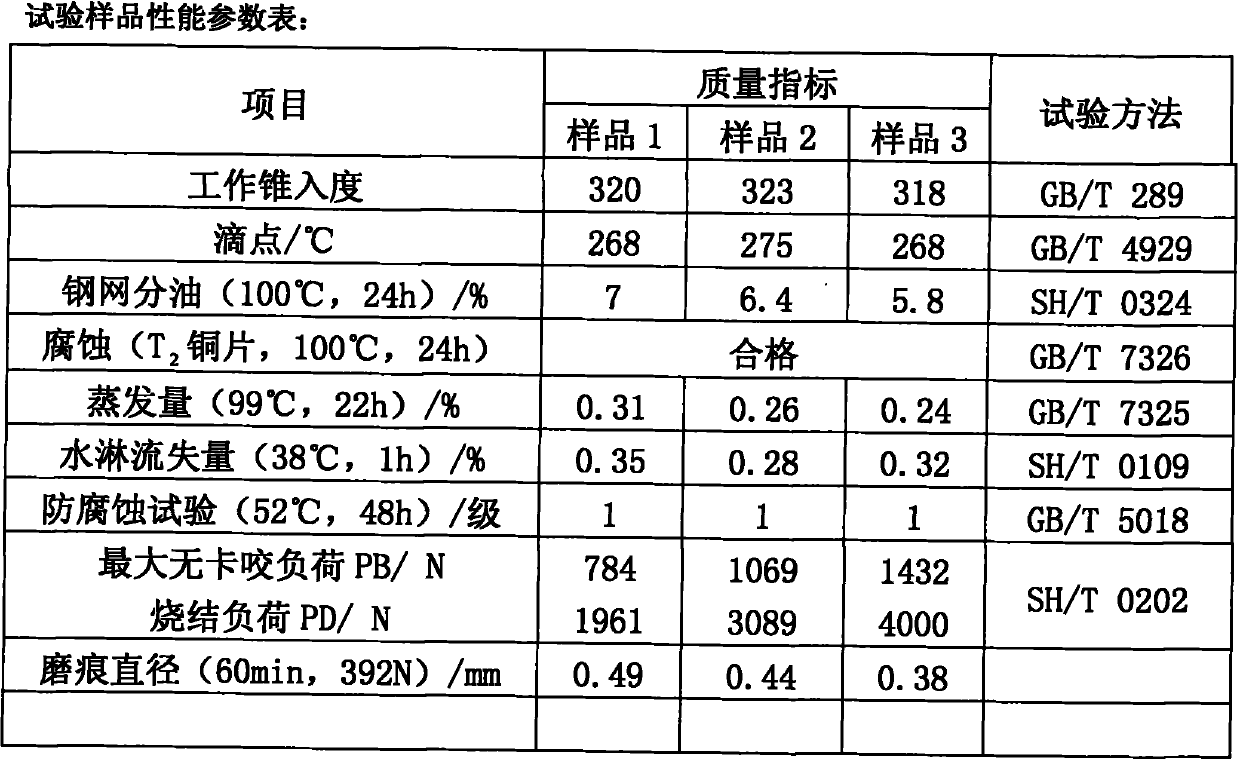

Examples

Embodiment 1

[0036] (1) Mixing: Add about 280g of mixed base oil, 80g of lauryl hydroxystearic acid, and 20g of stearic acid into the reaction kettle, raise the temperature to 100°C, and the stirring speed is 40r / min.

[0037] The base oil is a mixed oil of mineral oil, ester oil, and PAO synthetic hydrocarbon, and its kinematic viscosity at 100° C. is (130) mm2 / s.

[0038] Among the base oils, the mineral oil is mainly selected from 150BS, the synthetic hydrocarbon PAO is selected from PAO 4#, and the ester oil is selected from neopentyl polyol higher fatty acid ester 150#. The base oil content accounts for about 84% of the total grease.

[0039] The fatty acid is a mixture of 12 hydroxystearic acid and stearic acid; the ratio of the 12 hydroxystearic acid to stearic acid is 4:1.

[0040] (2) Saponification reaction: After fully mixing, add a measured lithium hydroxide aqueous solution, heat up to 100°C in the reaction kettle, and carry out saponification reaction at a stirring speed of ...

Embodiment 2

[0056] (1) Mixing: Add about 270g of mixed base oil, 80g of lauryl hydroxystearic acid, and 20g of stearic acid into the reaction kettle, raise the temperature to 100°C, and the stirring speed is 40r / min.

[0057] The base oil is a mixed oil of mineral oil, ester oil, and PAO synthetic hydrocarbon, and its kinematic viscosity at 100° C. is (130) mm2 / s.

[0058] Among the base oils, the mineral oil is mainly selected from 150BS, the synthetic hydrocarbon PAO is selected from PAO 8#, and the ester oil is selected from neopentyl polyol higher fatty acid ester 100#. The base oil content accounts for 83% of the total grease.

[0059] The fatty acid is a mixture of 12 hydroxystearic acid and stearic acid; the ratio of the 12 hydroxystearic acid to stearic acid is 4:1.

[0060] (2) Saponification reaction: After fully mixing, add a measured lithium hydroxide aqueous solution, heat up to 100°C in the reaction kettle, and carry out saponification reaction at a stirring speed of 50r / mi...

Embodiment 3

[0077] (1) Mixing: Add about 260g of mixed base oil, 80g of lauryl hydroxystearic acid, and 20g of stearic acid into the reaction kettle, heat up to 100°C, and stir at a speed of 40r / min.

[0078] The base oil is a mixed oil of mineral oil, ester oil, and PAO synthetic hydrocarbon, and its kinematic viscosity at 100° C. is (130) mm2 / s.

[0079] The mineral oil in the base oil is mainly selected from 150BS, the synthetic hydrocarbon PAO is selected from PAO 4# and PAO 8# mixed oil, and the ester oil is selected from neopentyl polyol advanced fatty acid ester 100# and 150# mixed oil. The base oil content accounts for 82% of the total grease.

[0080] The fatty acid is a mixture of 12 hydroxystearic acid and stearic acid; the ratio of the 12 hydroxystearic acid to stearic acid is 4:1.

[0081] (2) Saponification reaction: After fully mixing, add a measured lithium hydroxide aqueous solution, heat up to 125°C in the reaction kettle, and carry out saponification reaction at a stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com