Filter paper for cooling system in wire electrical discharge machining (WEDM) and production method of filter paper

A technology of a cooling system and a production method, applied in the field of papermaking, can solve the problems of short service life, large pore size of filter paper, deformation of filter paper, etc., and achieve the effects of improving dimensional stability, improving filtration precision and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

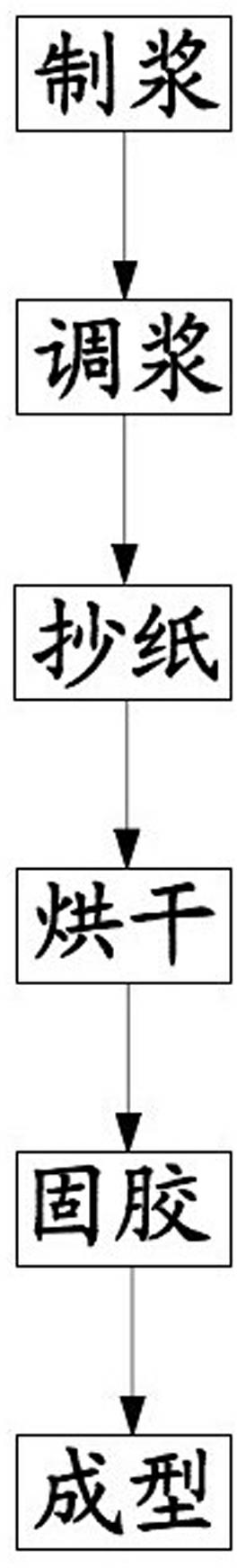

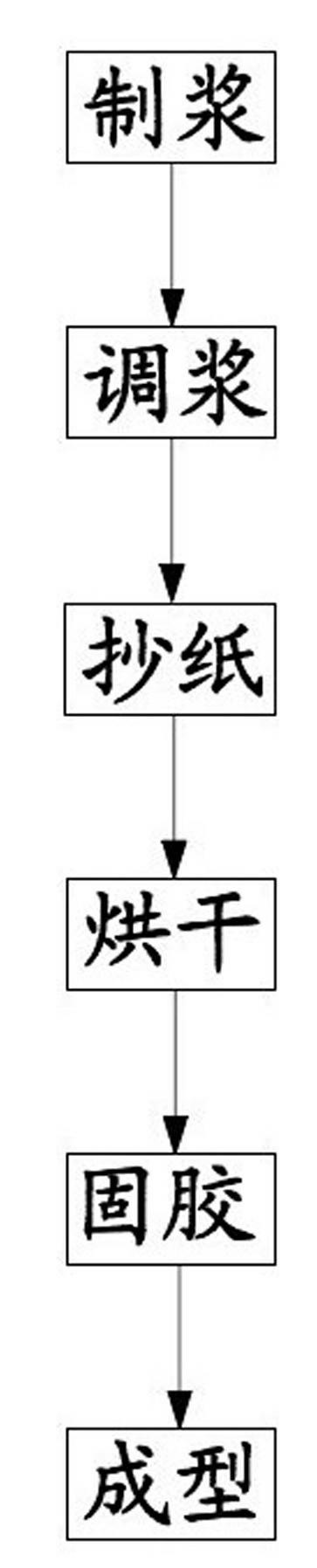

Method used

Image

Examples

Embodiment 1

[0063] Base paper absolute dry basis weight 115g / m 2 , the absolute dry basis weight of the paper is 150 g / m 2 . Slurry ratio: 60 parts of bleached coniferous pine pulp, 30 parts of bleached broad-leaved eucalyptus pulp, 5 parts of superfine glass fiber, 5 parts of polyester fiber, 0.8 parts of PPE wet strength agent and wet strength accelerator HBS-4B are added to the pulp 0.8 servings. The wire speed is 22 m / min, the mass concentration of coated phenolic resin is 20%, and the final coating amount is 23% (referring to the percentage of phenolic resin in the finished paper, calculated by weight: about 30 parts of phenolic resin). The test results are as follows: the paper air permeability is 85L / m 2 .s, the maximum pore size is 53μm, the average pore size is 34μm, the wet elongation is 0.7%, the wet bursting strength is 380KPa, the filtration precision is 8μm, the impurity removal rate reaches 99.3%, and the use time is 29 days.

Embodiment 2

[0065] Base paper absolute dry basis weight 120g / m 2 , the absolute dry weight of the paper is 160 g / m 2 , Slurry ratio: 65 parts of bleached coniferous pine pulp, 28 parts of bleached broad-leaved eucalyptus pulp, 3 parts of ultrafine glass fiber, 4 parts of polyester fiber, 0.5 part of PPE wet strength agent, wet strength accelerator HBS are added to the pulp -4B 0.7 parts. The speed of the wire part is 21 m / min, the mass concentration of the coated phenolic resin is 18%, and the final coating amount is 20% (referring to the percentage of the phenolic resin in the finished paper, calculated by weight: about 25 parts of the phenolic resin). The test results are as follows: the paper air permeability is 82L / m 2 .s, the maximum pore size is 51μm, the average pore size is 33μm, the wet elongation is 0.6%, the wet bursting strength is 420KPa, the filtration precision is 7μm, the impurity removal rate reaches 99.4%, and the use time is 30 days.

Embodiment 3

[0067] Base paper dry basis weight 135g / m2, finished paper dry basis weight 172 g / m2, pulp ratio: 68 parts of bleached coniferous pine pulp, 25 parts of bleached broad-leaved eucalyptus pulp, 2 parts of superfine glass fiber, 5 parts of polyester fiber 1 part, 1 part of PPE wet strength agent and 1 part of wet strength accelerator HBS-4B are added to the slurry. The speed of the wire part is 20 m / min, the mass concentration of the coated phenolic resin is 19%, and the final coating amount is 21% (referring to the percentage of the phenolic resin in the finished paper, calculated by weight: about 27 parts of the phenolic resin). The test results are as follows: the paper air permeability is 88L / m 2 .s, the maximum pore size is 54μm, the average pore size is 32μm, the wet elongation is 0.45%, the wet bursting strength is 490KPa, the filtration precision is 8μm, the impurity removal rate reaches 99.52%, and the use time is 34 days.

[0068] As can be seen from the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com