Preparation method of multi-scale spherical-grain hard alloy material

A technology of cemented carbide and spherical crystals, which is applied in metal processing equipment, coating, transportation and packaging, etc., can solve the problems that are difficult to effectively solve the problem of tungsten carbide phase sharp angle effect in the cemented carbide structure, and achieve the purpose of suppressing grains The effect of growing up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

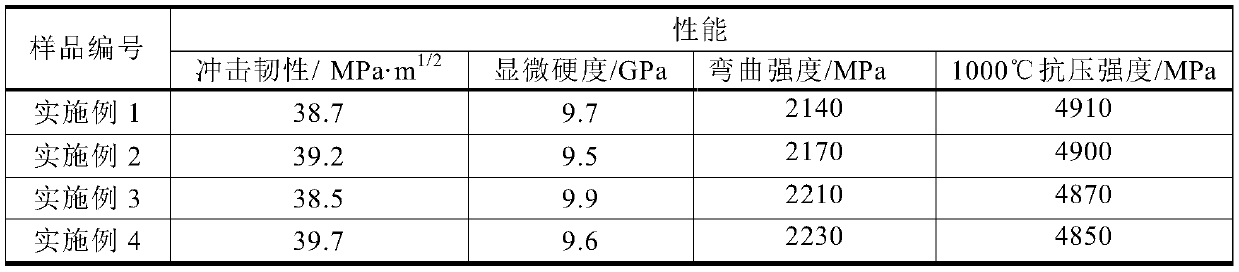

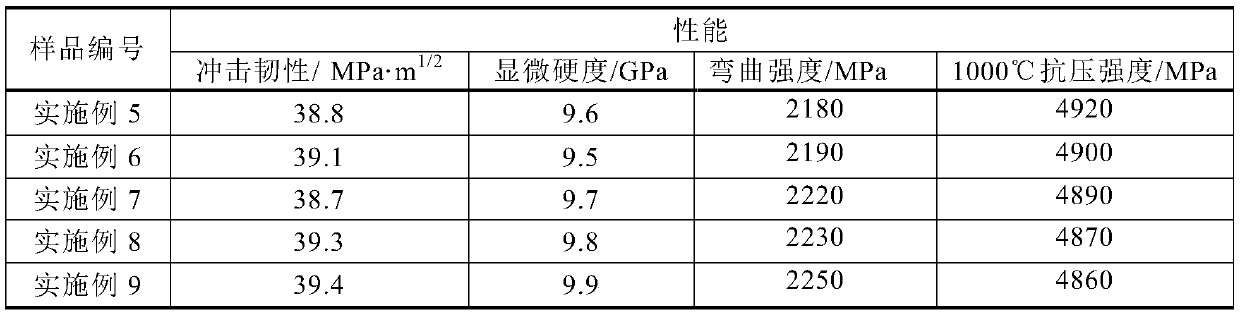

Examples

preparation example Construction

[0019] A kind of preparation method of multi-scale spherical crystal cemented carbide material of the present invention, comprises the following steps:

[0020] (1) The reduced tungsten carbide powder is subjected to positive pressure shear micro-grinding treatment, the positive pressure is 12-25MPa, the shear force is 7-15MPa, and then selective nano-cobalt plating is carried out. The plating steps include palladium, ammoniation and micro-grinding. Plating, the concentration of cobalt nitrate in the plating solution is 3 to 6mol / L, and the plating temperature is 55 to 85°C to obtain a local cobalt film wrapped polygonal tungsten carbide composite powder;

[0021] (2) Partial cobalt film-wrapped polygonal tungsten carbide composite powder is added to 60% SAN180# gasoline solution for roller milling and granulation. The mass ratio of powder to glue is (87.6-95.1): (4.9-12.4), and high-temperature steady-state recrystallization after degreasing Treatment, the degreasing temperat...

Embodiment 1

[0026] (1) The reduced tungsten carbide powder is subjected to positive pressure shearing and micro-grinding treatment, positive pressure 15MPa, shear force 15MPa, and then selective nano-cobalt plating, the plating step includes palladium, ammoniation and microplating, plating solution The concentration of cobalt nitrate in the medium is 3mol / L, and the plating temperature is 55°C to obtain a partial cobalt film-wrapped polygonal tungsten carbide composite powder;

[0027] (2) Partial cobalt film-wrapped polygonal tungsten carbide composite powder is added to 60% SAN180# gasoline solution for roller milling and granulation. The mass ratio of powder to glue is 87.6:12.4. After degreasing, high-temperature steady-state recrystallization treatment is carried out. The degreasing temperature is 550°C. The high-temperature steady-state recrystallization treatment temperature is 1280°C, the average heating and cooling rate is 1.4°C / min, and the holding time is 8 hours to obtain multi...

Embodiment 2

[0030] (1) The reduced tungsten carbide powder is subjected to positive pressure shear micro-grinding treatment, the positive pressure is 13MPa, the shear force is 8MPa, and then selective nano-cobalt plating is carried out. The plating steps include palladium, ammoniation and microplating, and the plating solution The concentration of cobalt nitrate in the medium is 4mol / L, and the plating temperature is 65°C to obtain a partial cobalt film-wrapped polygonal tungsten carbide composite powder;

[0031] (2) Partial cobalt film-wrapped polygonal tungsten carbide composite powder is added to 60% SAN180# gasoline solution for roller milling and granulation. The mass ratio of powder to glue is 89:11. After degreasing, high-temperature steady-state recrystallization treatment is carried out. The degreasing temperature is 550°C. The high-temperature steady-state recrystallization treatment temperature is 1380°C, the average heating and cooling rate is 1.6°C / min, and the holding time i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com