Low-density wear-resistant hard alloy material and preparation method thereof

A cemented carbide and low-density technology, applied in the field of cemented carbide, can solve the problems of increased material, installation cost, large proportion of cemented carbide, wear and other problems, and achieve high-efficiency preparation, high precision of composition control, and improved temperature concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

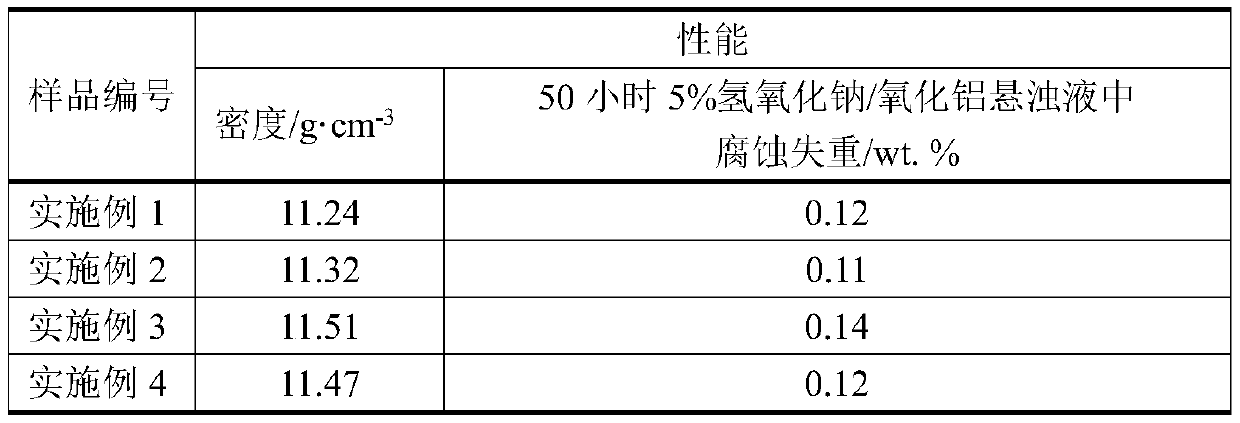

Examples

preparation example Construction

[0022] A kind of preparation method of low-density wear-resistant cemented carbide material of the present invention, comprises the following steps:

[0023] (1) Weigh 89.1%-91.6% of tungsten carbide powder by mass percentage: 8.2%-11.3% of cobalt powder: 0.2%-0.4% of calcium carbonate powder, mix the powder with a three-dimensional eddy current mixer, and the rotor speed is 70 rpm, Mix for 40 minutes, put the powder into a cold press to form a cylindrical green body after mixing evenly, the cold press pressure is 200MPa, and hold the pressure for 3 minutes;

[0024] (2) Put the prefabricated body and the nickel-based high-temperature solder into the high-temperature conductive mold according to the mass ratio of 82.4% to 83.2%: 16.8% to 17.6%. The composition of the nickel-based high-temperature solder is 86Ni 5Cr 2Si 4B 3Fe, which is conductive at high temperature The mold consists of three parts: high-temperature steel indenter, graphite sleeve and plaster mold. It is fired...

Embodiment 1

[0027] (1) Weigh tungsten carbide powder 89.8% by mass percentage: cobalt powder 10%: calcium carbonate powder 0.2%, mix the powder with a three-dimensional vortex mixer, the rotor speed is 70 rpm, mix for 40 minutes, and load the powder after mixing evenly Enter the cold press to make a cylindrical green body, the cold pressing pressure is 200MPa, and the pressure is maintained for 3 minutes;

[0028] (2) Put the prefabricated body and the nickel-based high-temperature solder into the high-temperature conductive mold according to the mass ratio of 82.9%:17.1%, the composition of the nickel-based high-temperature solder is 86Ni 5Cr 2Si 4B 3Fe, and the high-temperature conductive mold includes a high-temperature steel pressure head It is composed of three parts, graphite sleeve and plaster mold, which are fired into low-density cemented carbide materials in a biaxial high-pressure infiltration device. The firing process is: biaxial pressure 4.2GPa, temperature 1150°C, and heat p...

Embodiment 2

[0030] (1) Weigh tungsten carbide powder 91.2% by mass percentage: cobalt powder 8.4%: calcium carbonate powder 0.4%, mix the powder with a three-dimensional vortex mixer, the rotor speed is 70 rpm, mix for 40 minutes, and load the powder after mixing evenly Enter the cold press to make a cylindrical green body, the cold pressing pressure is 200MPa, and the pressure is maintained for 3 minutes;

[0031] (2) Put the prefabricated body and the nickel-based high-temperature solder into the high-temperature conductive mold according to the mass ratio of 82.5%:17.5%, the composition of the nickel-based high-temperature solder is 86Ni 5Cr 2Si 4B 3Fe, and the high-temperature conductive mold includes a high-temperature steel pressure head Composed of three parts, graphite sleeve and plaster mold, low-density cemented carbide materials are fired in a biaxial high-pressure infiltration device. The firing process is: biaxial pressure 4.5GPa, temperature 1180 ° C, and heat preservation fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com