Preparation method of yttrium oxide photoexcited synergistically fine-grained high-alumina bronze indicator coating

A high-aluminum bronze, fine-grain strengthening technology, applied in coating, metal material coating process, melt spraying and other directions, can solve the problems of high cost of production data, difficult to promote, etc., to achieve process stability and repeatability, High-precision component control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A preparation method of yttrium oxide photoexcited synergistically fine-grained high-alumina bronze indicator coating, comprising the following steps:

[0021] (1) Clean the surface of the 45# steel substrate with ultrasonic waves, use a semi-automatic acid spraying machine to roughen the sprayed welding surface of the substrate after cleaning, the diameter of the nozzle is 0.5mm, the amount of acid sprayed is 20ml / min, and the acid component: 27ml of nitric acid , hydrofluoric acid 62ml, distilled water 270ml.

[0022] (2) Put the treated substrate into a heat treatment furnace to preheat to 260°C-300°C, and the preheating heating rate is 10°C / min;

[0023] (3) Weigh high-alumina bronze powder and yttrium oxide powder according to the mass percentage of 99.4-99.8:0.2-0.6, perform mechanical alloying in a stirring ball mill, the rotor speed is 290 rpm, and the grinding ball is 3mm ZrO 2 Ball, ball milling time 25 hours, ball milling medium is absolute ethanol, material...

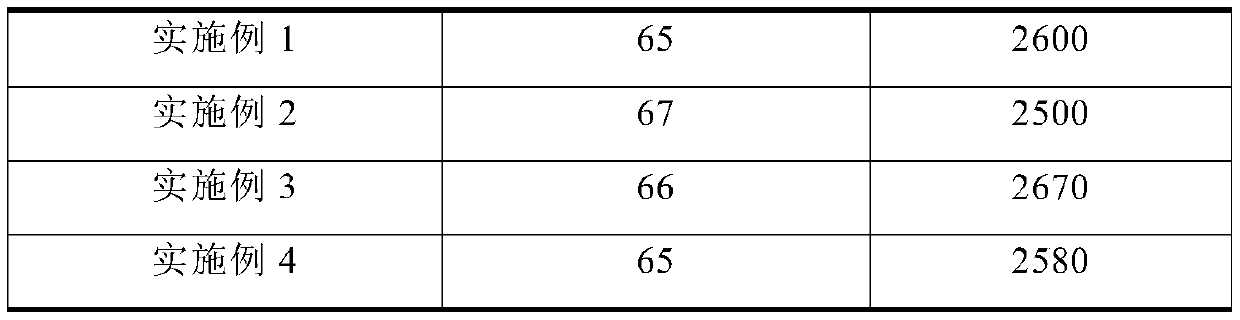

Embodiment 1

[0027] (1) Clean the surface of 45# steel substrate with ultrasonic waves, and use a semi-automatic acid spraying machine to roughen the sprayed welding surface of 45# steel substrate after cleaning. The diameter of the nozzle is 0.5mm, and the amount of acid sprayed is 20ml / min. : Nitric acid 27ml, hydrofluoric acid 62ml, distilled water 270ml;

[0028] (2) Put the treated substrate into a heat treatment furnace to preheat to 270°C, and the preheating heating rate is 10°C / min;

[0029] (3) Weigh the high-alumina bronze powder and yttrium oxide powder according to the mass percentage of 99.4:0.6, carry out mechanical alloying in the stirring ball mill, the rotor speed is 290 rpm, and the grinding ball is 3mm ZrO 2 Balls, the ball milling time is 25 hours, the ball milling medium is absolute ethanol, according to the mass ratio, material: ball: absolute ethanol = 1:18:0.2;

[0030] (4) Dry the powder with a high-speed centrifugal spray dryer, the rotational speed of the centri...

Embodiment 2

[0032] (1) Clean the surface of 45# steel substrate with ultrasonic waves, and use a semi-automatic acid spraying machine to roughen the sprayed welding surface of 45# steel substrate after cleaning. The diameter of the nozzle is 0.5mm, and the amount of acid sprayed is 20ml / min. : Nitric acid 27ml, hydrofluoric acid 62ml, distilled water 270ml;

[0033] (2) Put the treated substrate into a heat treatment furnace to preheat to 290°C, and the preheating heating rate is 10°C / min;

[0034] (3) Weigh the high-alumina bronze powder and yttrium oxide powder according to the mass percentage of 99.6:0.4, carry out mechanical alloying in the stirring ball mill, the rotor speed is 290 rpm, and the grinding ball is 3mm ZrO 2 Balls, the ball milling time is 25 hours, the ball milling medium is absolute ethanol, according to the mass ratio, material: ball: absolute ethanol = 1:18:0.2;

[0035] (4) Dry the powder with a high-speed centrifugal spray dryer, the rotational speed of the centri...

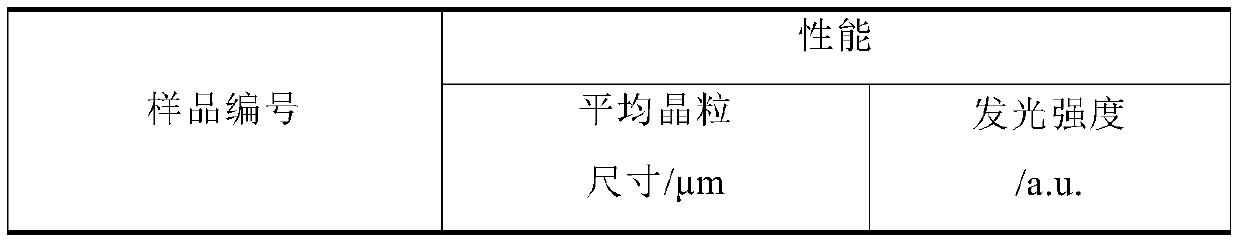

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com