Stripped tungsten alloy material with self-sharpening structure, as well as preparation method and application thereof

A technology of tungsten alloy and tungsten-nickel-iron alloy, which is applied in the field of self-sharpening structure tungsten alloy material and its preparation, can solve the problem of limited control level of adiabatic shear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a method for preparing a layer-peeling self-sharpening structure tungsten alloy material, comprising the following steps:

[0021] The mixed powder obtained by mixing tungsten oxide powder, nickel oxide powder and iron oxide powder is subjected to pulse reduction plasma jet treatment and cooling treatment to obtain tungsten-nickel-iron pre-alloyed powder;

[0022] The tungsten-nickel-iron pre-alloyed powder is subjected to four-stage roller forming treatment to obtain plate-shaped tungsten-nickel-iron alloy;

[0023] performing roll bending deformation treatment on the plate-shaped tungsten-nickel-iron alloy to obtain deformed tungsten-nickel-iron alloy;

[0024] The deformed tungsten-nickel-iron alloy is subjected to warm-pressing and densification treatment to obtain a tungsten alloy material with exfoliated self-sharpening structure.

[0025] In the present invention, unless otherwise specified, the raw materials and equipment used are commerc...

Embodiment 1

[0035] (1) In terms of mass percentage, take 92.70% tungsten oxide powder (with a particle size of 2-6 μm), 5.33% nickel oxide powder (with a particle size of 2-6 μm) and 1.97% iron oxide powder (with a particle size of 2-6 μm) and mix evenly, The obtained mixed powder is subjected to pulse reduction plasma jet treatment and cooling treatment to obtain tungsten-nickel-iron pre-alloyed powder; wherein, the operating conditions include: the plasma source is a mixture of argon and hydrogen, and the volume ratio of argon and hydrogen is 6 : 4; the pulse current is 2.3A, and the pulse frequency is 6.8Hz; based on the mass of the mixed powder, the treatment efficiency of the pulse reduction plasma jet treatment is 7s / g; the cooling medium is 3°C circulating water;

[0036] (2) Send the tungsten-nickel-iron pre-alloyed powder into a four-stage roller forming integrated device for forming to obtain a plate-shaped tungsten-nickel-iron alloy; wherein, the operating conditions include: th...

Embodiment 2~8

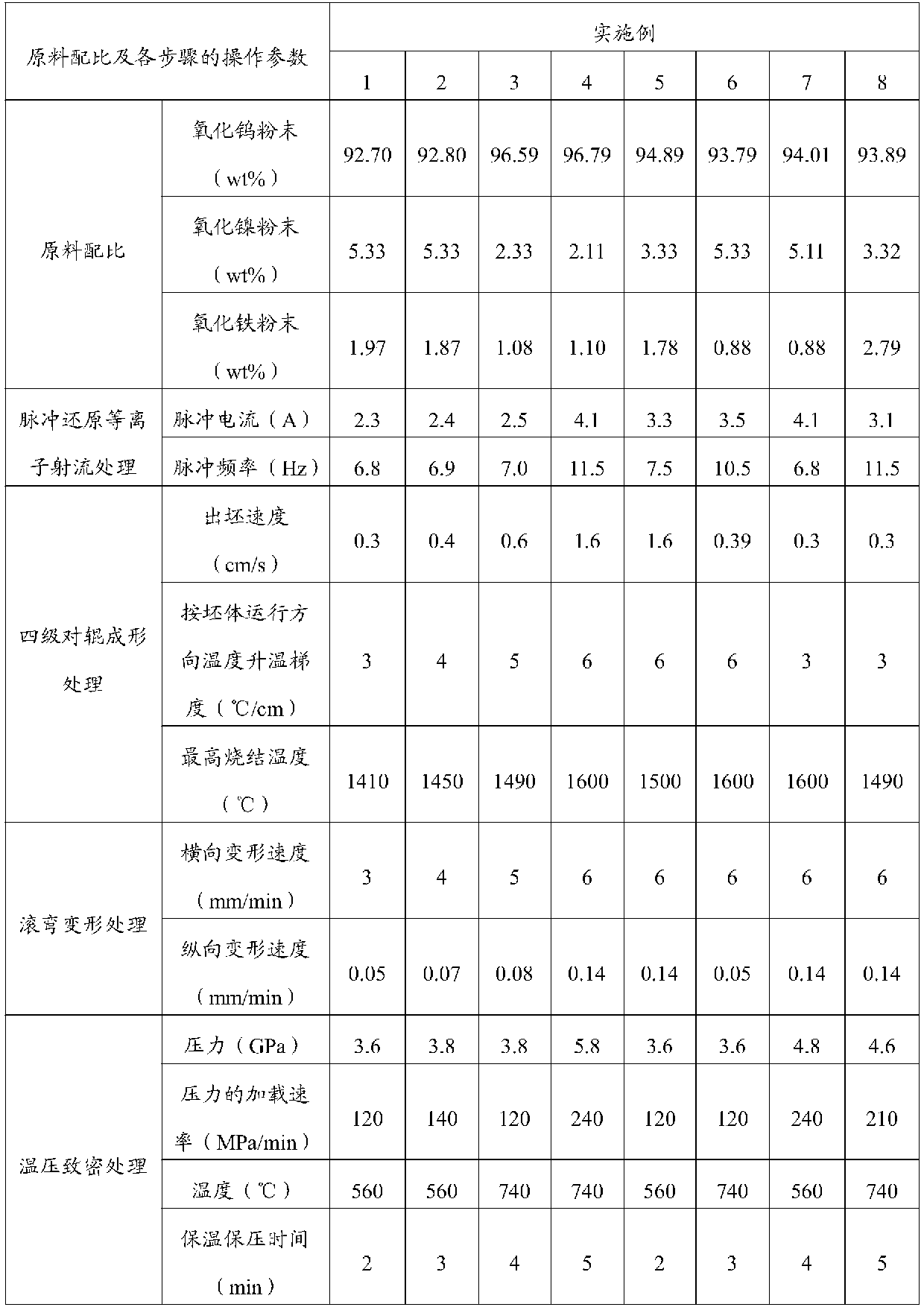

[0040] According to the method of Example 1, the peeled self-sharpening structure tungsten alloy material is prepared, and the ratio of raw materials and the operating parameters of each step are shown in Table 1 (the operating conditions or parameters not listed in Table 1 are the same as Example 1).

[0041] Raw material proportioning and the operation parameter of each step in the embodiment 1~8 of table 1

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com