Method for preparing microcrystalline foam glass from vanadium-titanium magnet tailings

A technology of microcrystalline foam glass and vanadium-titanium magnet, applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of difficulty in increasing the added value of vanadium-titanium magnet tailings industry, etc., so as to improve glass toughness and improve utilization The effect of increasing the foaming porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

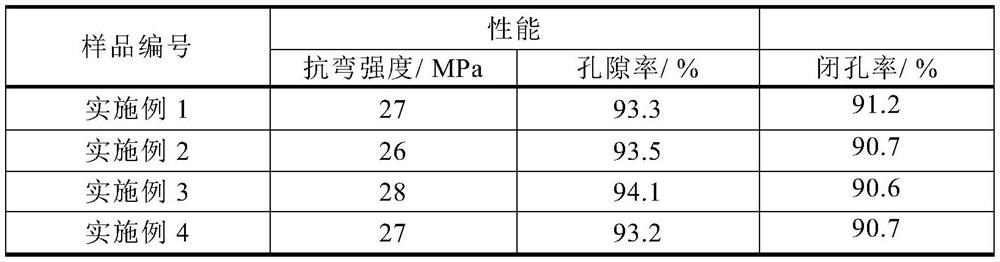

Examples

Embodiment 1

[0025] (1) After the vanadium-titanium magnet tailings are washed and dried, they are activated in hydrofluoric acid with a concentration of 0.5mol / L. The activation equipment is a gravity induction magnetic stirrer, and then a sodium hydroxide solution with a concentration of 0.3mol / L is added. Neutralize, precipitate, and wash to obtain active vanadium-titanium magnet tailings;

[0026] (2) Mix and ball mill active vanadium-titanium magnet tailings, carbon powder, flat glass powder, silicon dioxide powder, calcium oxide powder, and sodium oxide powder in a ratio of 76:1.2:9.1:9.3:1.1:3.3, and then add mass concentration It is 3.5% PVA alcohol forming agent, which is placed in a cold press mold and pressed into shape, and the cold press pressure is 68MPa; the ball mill is carried out in a ball mill tank, and the ball mill time is 20 hours. The material of the ball mill tank is nylon, and the material of the ball mill is zirconia. The speed is 170 rpm.

[0027] (3) Put the co...

Embodiment 2

[0029] (1) After the vanadium-titanium magnet tailings are washed and dried, they are activated in hydrofluoric acid with a concentration of 1.1mol / L. The activation equipment is a gravity induction magnetic stirrer, and then a sodium hydroxide solution with a concentration of 0.8mol / L is added. Neutralize, precipitate, and wash to obtain active vanadium-titanium magnet tailings;

[0030] (2) Mix and ball mill active vanadium-titanium magnet tailings, carbon powder, flat glass powder, silica powder, calcium oxide powder, and sodium oxide powder in a ratio of 70:1.2:10.1:10.3:3.1:5.3, and then add mass concentration It is 3.5% PVA alcohol forming agent, which is placed in a cold press mold and pressed into shape, with a cold press pressure of 98 MPa; the ball mill is carried out in a ball mill tank, and the ball milling time is 16 hours. The material of the ball mill tank is nylon, and the material of the ball mill is zirconia. The speed is 165 rpm.

[0031] (3) Put the cold-p...

Embodiment 3

[0033] (1) After the vanadium-titanium magnet tailings are washed and dried, they are activated in hydrofluoric acid with a concentration of 0.8mol / L. The activation equipment is a gravity induction magnetic stirrer, and then a sodium hydroxide solution with a concentration of 0.7mol / L is added. Neutralize, precipitate, and wash to obtain active vanadium-titanium magnet tailings;

[0034] (2) Mix and ball mill active vanadium-titanium magnet tailings, carbon powder, flat glass powder, silicon dioxide powder, calcium oxide powder, and sodium oxide powder in a ratio of 68:1.2:11.1:11.3:3.1:5.3, and then add mass concentration It is 3.5% PVA alcohol forming agent, which is placed in a cold press mold and pressed into shape, and the cold press pressure is 70MPa; the ball mill is carried out in a ball mill tank, and the ball mill time is 15 hours. The material of the ball mill tank is nylon, and the material of the ball mill is zirconia. The speed is 160 rpm.

[0035] (3) Put the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com