Low-tungsten-carbide-adjacency hard alloy and preparing method thereof

A cemented carbide and tungsten carbide adjacent technology, which is applied in the field of low tungsten carbide adjacent cemented carbide and its preparation, can solve the problems of reduced toughness of cemented carbide and increased WC/WC adjacent degree, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a method for preparing a cemented carbide with low tungsten carbide contiguity, comprising the following steps:

[0021] The tungsten carbide powder is spheroidized and sieved in sequence to obtain sieved powder;

[0022] Spraying a cobalt film on the surface of the sieved powder to obtain a cobalt film tungsten carbide composite powder;

[0023] Mixing the cobalt film tungsten carbide composite powder and tantalum carbide powder, performing interfacial diffusion heat treatment under stirring conditions, to obtain a precursor powder;

[0024] The precursor powder is sintered to obtain a cemented carbide with low tungsten carbide contiguity.

[0025] In the present invention, unless otherwise specified, the raw materials and equipment used are commercially available items well known to those skilled in the art.

[0026] In the invention, the tungsten carbide powder is sequentially subjected to spheroidization treatment and sieving treatment to ob...

Embodiment 1

[0036](1) Put tungsten carbide powder with an average particle size of 19 μm into a disc-type micro-shear grinding device for spheroidization treatment to obtain spheroidized powder; wherein, in the disc-type micro-shear grinding device, silicon carbide is inlaid with Miniature grinding cones, the miniature grinding cones are arranged in the form of involutes, the distance between two adjacent micro grinding cones is 7μm, the spindle speed is 112r / min, based on the mass of tungsten carbide powder, the efficiency of spheroidizing treatment is 1.5h / kg;

[0037] (2) Sieving the spheroidized powder with a vibrating sieve to obtain a sieved powder with a particle size of 17-19 μm; wherein, the effective inner diameter of the screen is 30 μm, 18 μm, and 7 μm, and the vibration frequency is 15 Hz;

[0038] (3) The sieved powder is placed in a frequency-vibration rotary stirring and spraying cobalt device, with cobalt wire as the cobalt source and nitrogen as the medium, when the nit...

Embodiment 2~8

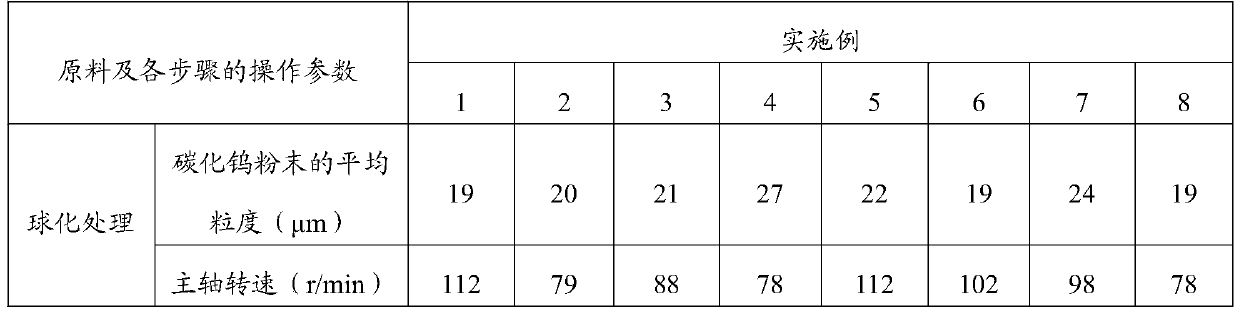

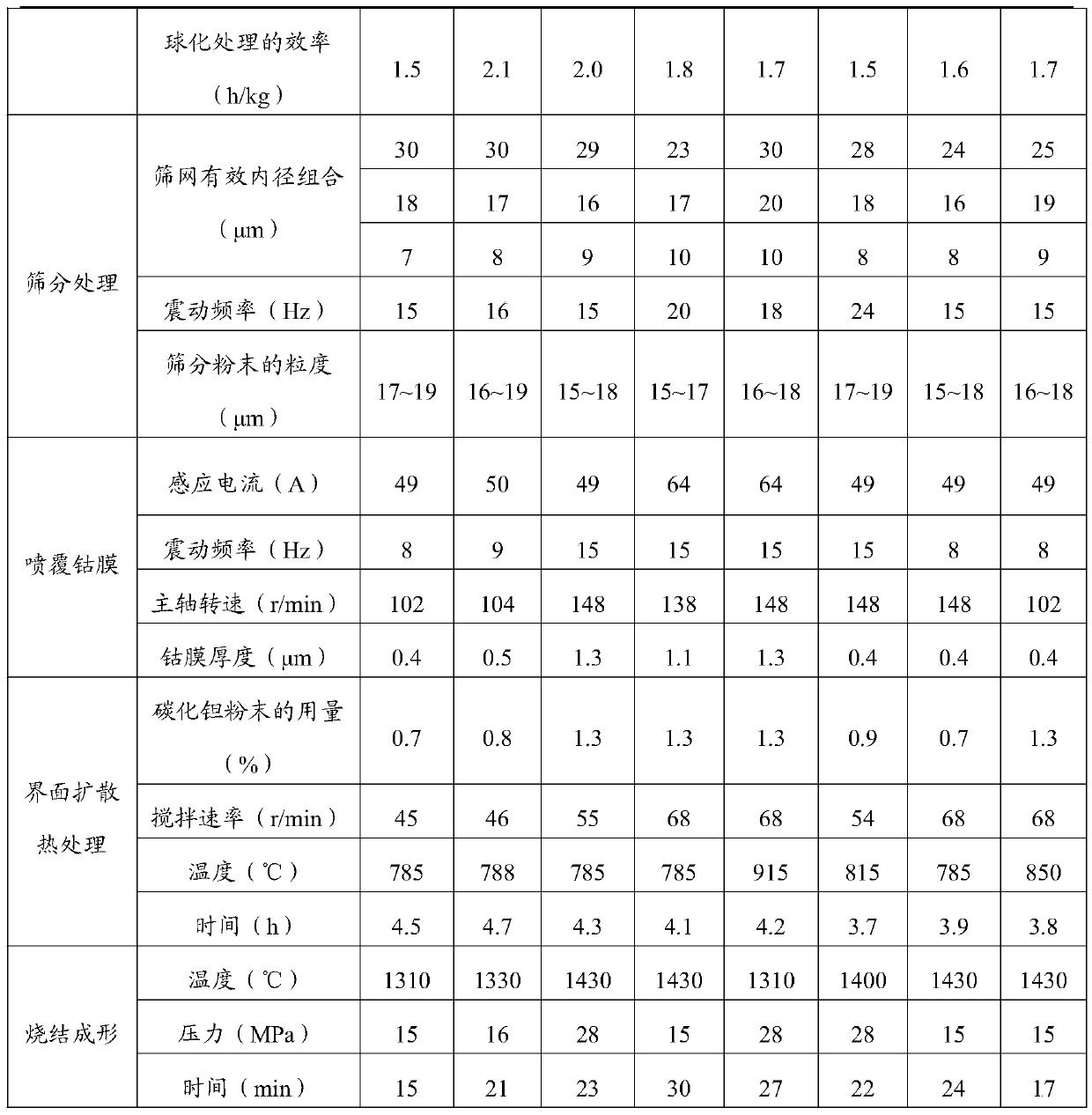

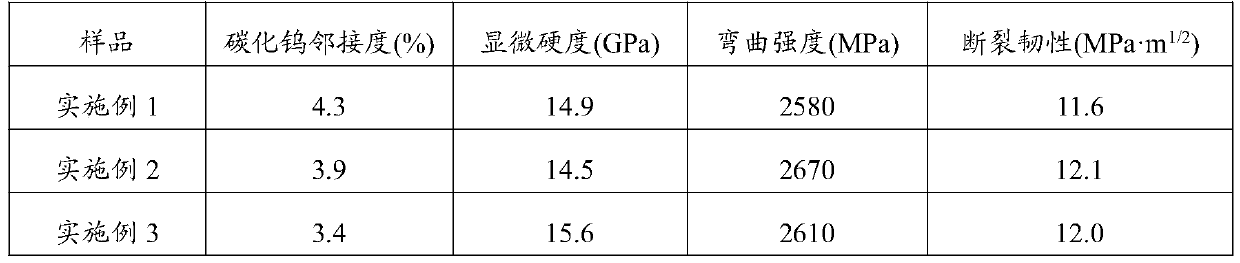

[0042] Prepare low tungsten carbide contiguity cemented carbide according to the method of embodiment 1, the operating parameters of raw material and each step are as shown in table 1 (operating conditions or parameters not listed in table 1 are identical with embodiment 1, the consumption of tantalum carbide powder Specifically, the mass of cobalt film tungsten carbide composite powder is taken as 1).

[0043] Raw materials and operating parameters of each step in Table 1 Examples 1-8

[0044]

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com