Preparation method of multilevel strip-shaped crystalline tungsten alloy material

A tungsten alloy and strip technology, applied in the field of high-density tungsten alloy preparation, can solve problems such as difficulty in greatly improving the performance of tungsten alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

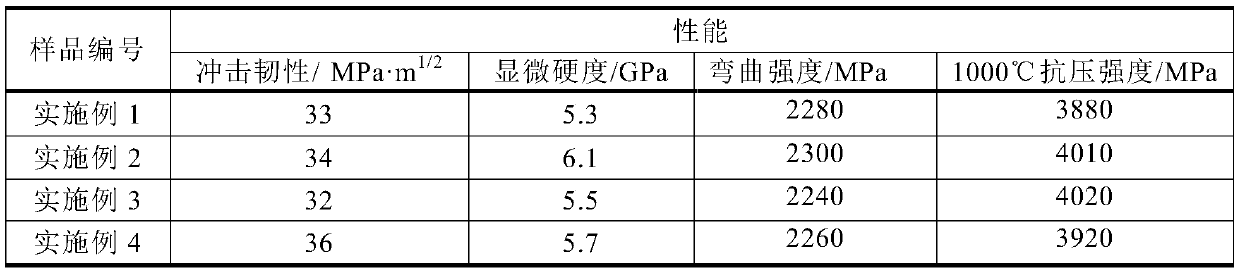

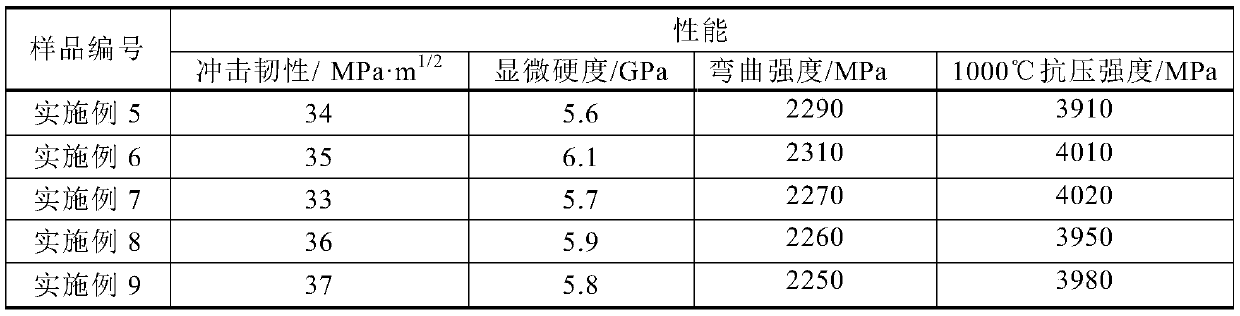

Examples

preparation example Construction

[0020] A method for preparing a multi-level strip crystal tungsten alloy material of the present invention comprises the following steps:

[0021] (1) Weigh tungsten powder, titanium powder and yttrium powder according to the mass percentage of 97.7~99.0:0.6~1.3:0.4~1.0, and carry out the overturning frequency vibration impact treatment, the overturning speed is 20~40 rpm, and the frequency vibration frequency is 4~8Hz , the impact treatment time is 23 to 35 hours, and the micron-scale lamellar tungsten-based composite powder is obtained;

[0022] (2) Add micron-scale lamellar tungsten-based composite powder to 50% SBS alcohol solution for continuous biaxial micro-branching treatment, wherein the powder mass ratio is (87.6-95.1): (4.9-12.4), continuous uniaxial The speed is 2~5rpm, the positive pressure is 4~7MPa, after degreasing at 530℃, it is mixed with liquid paraffin and pressed for molding. 378~435MPa, get green body;

[0023] (3) The green body is placed in a heat col...

Embodiment 1

[0027] (1) Weigh tungsten powder, titanium powder and yttrium powder according to the mass percentage of 99.0:0.6:0.4, and carry out the overturning frequency vibration impact treatment, the overturning speed is 20 rpm, the frequency vibration frequency is 5Hz, and the impact treatment time is 25 hours, and the micron level is obtained. Lamellar tungsten-based composite powder;

[0028] (2) Add micron-scale lamellar tungsten-based composite powder to 50% SBS alcohol solution for continuous biaxial micro-rolling, the powder mass ratio is 87.6:12.4, the continuous single-axis speed is 3 rpm, and the positive pressure is 5 MPa. After degreasing at 530°C, it is mixed with liquid paraffin and pressed into shape. The mass ratio of degreasing powder and molding agent is 94.6:5.4, and the molding pressure is 385MPa to obtain a green body;

[0029] (3) The green body is placed in a normal-pressure inert atmosphere heat collector to be fired and molded at a firing temperature of 1560° C...

Embodiment 2

[0031] (1) Weigh tungsten powder, titanium powder and yttrium powder according to the mass percentage of 98.2:1.0:0.8, and carry out the overturning frequency vibration impact treatment, the overturning speed is 30 rpm, the frequency vibration frequency is 5Hz, and the impact treatment time is 27 hours, and the micron level is obtained. Lamellar tungsten-based composite powder;

[0032] (2) Add micron-scale lamellar tungsten-based composite powder to 50% SBS alcohol solution for continuous biaxial micro-rolling, the powder mass ratio is 87.9:12.1, the continuous single-axis speed is 4 rpm, and the positive pressure is 7MPa. After degreasing at 530°C, it is mixed with liquid paraffin and pressed into shape. The mass ratio of degreasing powder and molding agent is 95.5:4.5, and the molding pressure is 398MPa to obtain a green body;

[0033] (3) The green body is placed in a normal-pressure inert atmosphere heat collection device for firing and molding at a firing temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com