Preparation method of complex-phase co-strengthening hard alloy material

A cemented carbide and pre-alloying technology, which is applied in the field of preparation of multiphase co-strengthened cemented carbide materials, can solve problems such as the contradiction between strength and toughness, the contradiction between strength and toughness, and restrictions on the promotion of new cemented carbide industries, so as to achieve guaranteed Effect of improving density and formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A kind of preparation method of multiphase co-reinforced cemented carbide material of the present invention, comprises the following steps:

[0022] (1) Put tungsten carbide powder, nickel aluminide powder, titanium carbonitride powder and nickel powder in the high energy ball mill according to mass ratio (8.9~9.3): 1 and (9.1~9.5): 1, respectively, for prealloying Chemical treatment to obtain two kinds of pre-alloyed powders. The speed of the ball mill is 480-550 r / min, the ball-to-material ratio (2.2-2.7): 1, and the material of the ball mill pot and balls is hard alloy;

[0023] (2) The two kinds of pre-alloyed powders are atomized, dried and granulated. The rotation speed of the atomizer is 22000-25000 rpm, the temperature of the air inlet / outlet is 210°C and 80°C respectively, and the particle size of the dry powder is 80-120μm. The obtained tungsten carbide-based, titanium carbonitride-based spherical powder and cobalt powder are mixed in a slow three-dimensional...

Embodiment 1

[0028] (1) Place tungsten carbide powder, nickel aluminide powder, titanium carbonitride powder, and nickel powder in a high-energy ball mill at a mass ratio of 8.9:1 and 9.1:1, respectively, and perform pre-alloying treatment to obtain pre-alloyed powder. The speed of the ball mill is 540 rpm, the ball-to-material ratio is 2.5:1, and the material of the ball mill pot and balls are all cemented carbide;

[0029] (2) The two pre-alloyed powders are atomized and dried to granulate, the atomizer speed is 22000 rpm, the air inlet / outlet temperatures are 210°C and 80°C respectively, and the particle size of the dry powder is 90μm. The prepared tungsten carbide Base, titanium carbonitride base spherical powder and cobalt powder are placed in a slow three-dimensional vortex mixer and mixed evenly at a mass percentage of 5.2:4.0:1, and the speed of the mixer is 30 rpm;

[0030] (3) The mixed powder is subjected to secondary atomization drying and granulation, packed into a cold-press ...

Embodiment 2

[0033] (1) Place tungsten carbide powder, nickel aluminide powder, titanium carbonitride powder, and nickel powder in a high-energy ball mill at a mass ratio of 9.1:1 and 9.2:1, respectively, and perform pre-alloying treatment to obtain pre-alloyed powder. The speed of the ball mill is 480 rpm, the ratio of ball to material is 2.8:1, and the materials of the ball mill and the ball are all cemented carbide;

[0034] (2) The two pre-alloyed powders are atomized and dried to granulate, the atomizer speed is 24,000 rpm, the air inlet / outlet temperatures are 210°C and 80°C respectively, and the particle size of the dry powder is 80μm. The prepared tungsten carbide Base, titanium carbonitride base spherical powder and cobalt powder are placed in a slow three-dimensional vortex mixer and mixed evenly at a mass percentage of 5.4:4.1:1, and the speed of the mixer is 30 rpm;

[0035] (3) The mixed powder is subjected to secondary atomization drying and granulation, packed into a cold-pr...

PUM

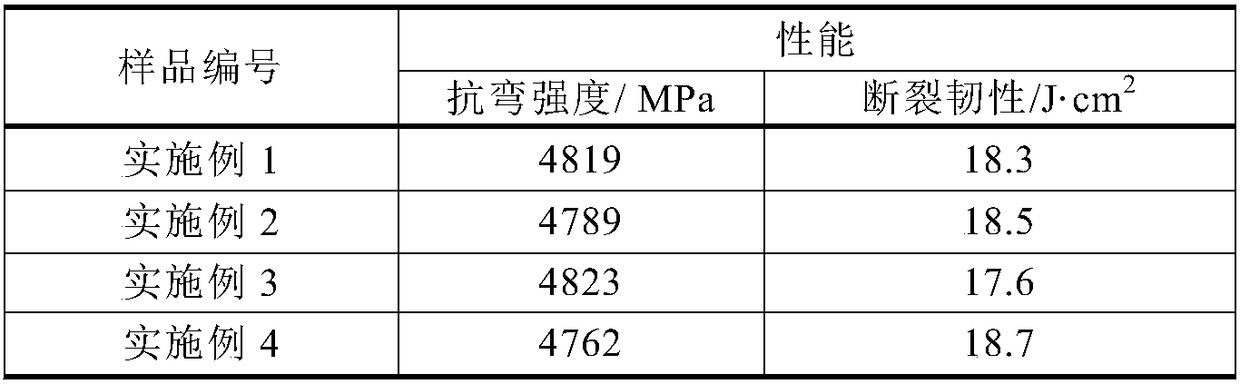

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com