Method for preparing porous ceramic material from vanadium-titanium magnetite tailings

A technology of vanadium-titanium magnetite and porous ceramics, which is applied in the production of ceramic materials, ceramic products, clay products, etc., can solve the problems that it is difficult to increase the industrial added value of vanadium-titanium magnetite tailings, and achieve the purpose of increasing industrial added value, The effect of high refining efficiency and uniform powder distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

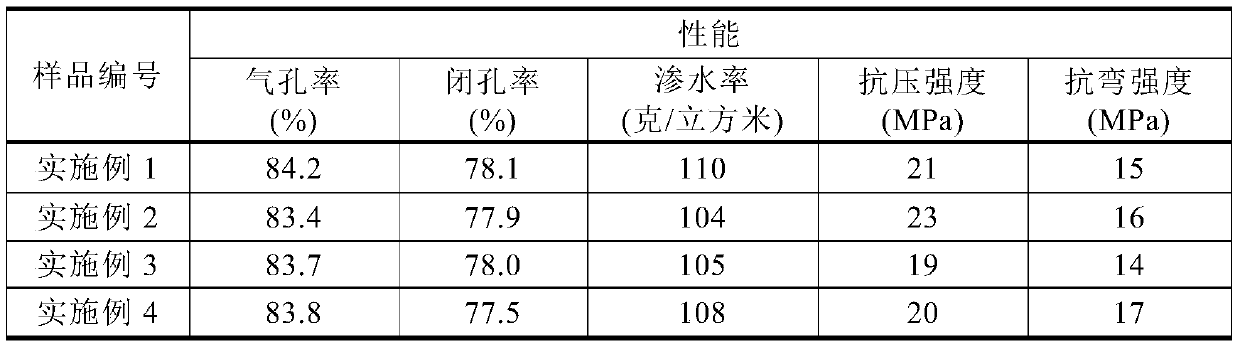

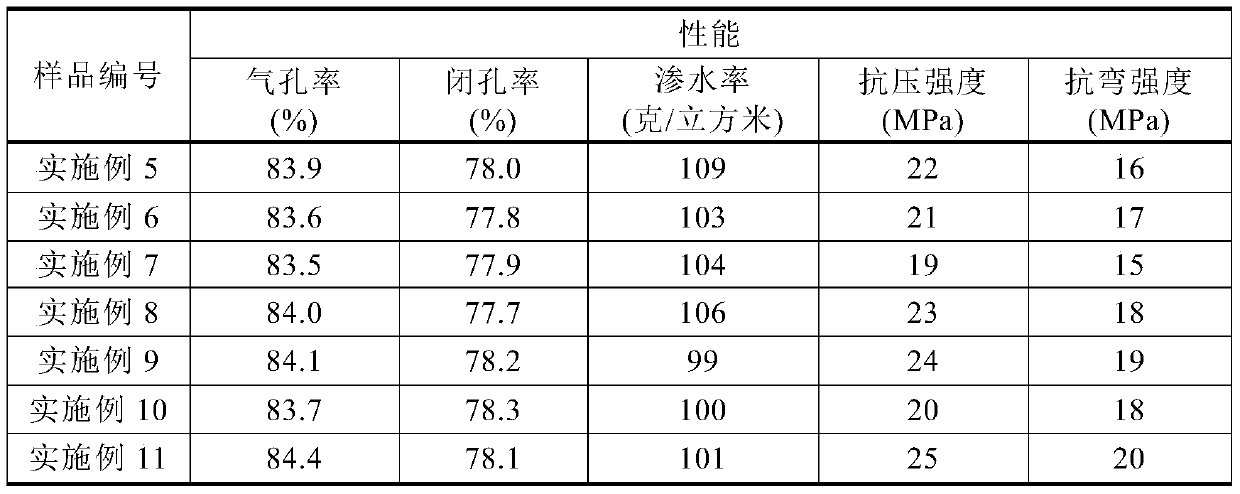

Examples

Embodiment 1

[0018] (1) The vanadium-titanium magnetite tailings are subjected to multi-acid leaching treatment, using a 3.3mol / L mixed solution of hydrochloric acid, nitric acid, and tungstic acid. The mixed molar percentage of the three acids is 45:22:33, and then mixed with alumina Powder, calcium carbonate powder and glass powder are put into the reflow type wheel blower device according to the mass percentage of 72:18:4:6 for refinement, the spindle speed is 110 rpm, and the wind speed is 100 m / s;

[0019] (2) Place the refined mixed powder in a slow-speed eccentric stirring device and add water to make a slurry at a speed of 140 rpm, then use filter cotton to separate water for water displacement treatment, and finally foam and form in a high-temperature blast heat collection device, The processing temperature is 1250°C, and the wind speed is 150 m / s, and finally a porous ceramic material is obtained.

Embodiment 2

[0021] (1) The vanadium-titanium magnetite tailings are subjected to multi-acid leaching treatment, using a 3.8mol / L mixed solution of hydrochloric acid, nitric acid, and tungstic acid, and the mixed molar percentage of the three acids is 47:23:30, and then mixed with alumina Powder, calcium carbonate powder and glass powder are put into the reflow type wheel mill blower device according to the mass percentage of 70:19.6:4.4:6 for refinement, the spindle speed is 120 rpm, and the wind speed is 80 m / s;

[0022] (2) Put the refined mixed powder in a slow-speed eccentric stirring device and add water to make slurry at a speed of 90 rpm, then use filter cotton to divide water for water displacement treatment, and finally foam and form in a high-temperature blast heat collection device, The processing temperature is 1250°C, and the wind speed is 120 m / s, and finally a porous ceramic material is obtained.

Embodiment 3

[0024] (1) The vanadium-titanium-magnetite tailings are subjected to the multi-acid leaching method, using a 5.2mol / L mixed solution of hydrochloric acid, nitric acid, and tungstic acid. The mixed molar percentage of the three acids is 43:24.6:32.4, and then mixed with alumina Powder, calcium carbonate powder and glass powder are put into the reflow type wheel blower device according to the mass percentage of 74:16.8:3.7:5.5 for refinement, the spindle speed is 130 rpm, and the wind speed is 110 m / s;

[0025] (2) Place the refined mixed powder in a slow-speed eccentric stirring device and add water to make a slurry at a speed of 140 rpm, then use filter cotton to separate water for water displacement treatment, and finally foam and form in a high-temperature blast heat collection device, The processing temperature is 1150°C, and the wind speed is 140 m / s, and finally a porous ceramic material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Water permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com