Preparation method of iron-based diamond tool material without graphitizing conversion

A tool material, graphitization technology, applied in diamond and other directions, can solve the problem of difficult to effectively overcome diamond graphitization and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

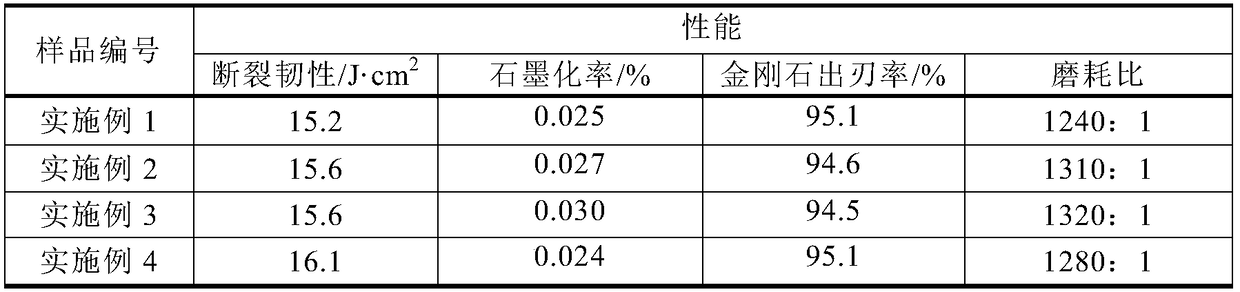

Examples

preparation example Construction

[0022] A kind of preparation method of iron-based diamond tool material of the present invention, comprises the following steps:

[0023] (1) Weigh iron powder, copper-tin alloy powder, and silicon powder according to the mass percentage of 84~91:7~13:2~6, homogenize them with an electric drive grinder, and the spindle speed is 120 rpm, and then place them on the surface Surface ionization is carried out in a high-energy device, the surface ionization beam is helium plasma, and the ionization time is 1.5 to 3.4 hours to obtain iron-based alloy powder;

[0024] (2) The diamond powder is purified, boiled, and rapidly quenched. The potassium phosphate aqueous solution with a concentration of 2.5-3.7mol / L is used for the boiling treatment. The instantaneous temperature spray quenching equipment is used for the rapid quenching treatment. The heating rate is 200°C / min, and the temperature is lowered. The speed is 670°C / min, and then crushed in a high-impact shearing machine. The pun...

Embodiment 1

[0028] (1) Weigh iron powder, copper-tin alloy powder, and silicon powder according to the mass percentage of 84:10:6, homogenize them with an electric drive grinder, and the spindle speed is 120 rpm, and then place them in a surface high-energy device for surface treatment. Ionization, the surface ionization beam is helium plasma, the ionization time is 1.5 hours, and the iron-based alloy powder is obtained;

[0029] (2) The diamond powder is purified, boiled, and quenched. The potassium phosphate aqueous solution with a concentration of 2.5mol / L is used for the boiling treatment. The quenching treatment adopts an instantaneous temperature spray quenching equipment. The heating rate is 200°C / min, and the cooling rate is 670 ℃ / min, then crushed in a high-impact shearing machine, the punch frequency of high-impact shearing and crushing is 140, and polygonal diamond powder is obtained;

[0030] (3) Weigh iron-based alloy powder and polygonal diamond powder according to the mass ...

Embodiment 2

[0032] (1) Weigh iron powder, copper-tin alloy powder, and silicon powder according to the mass percentage of 87:9:4, homogenize them with an electric drive grinder, and the spindle speed is 120 rpm, and then place them in a surface high-energy device for surface Ionization, the surface ionization beam is helium plasma, the ionization time is 1.8 hours, and the iron-based alloy powder is obtained;

[0033] (2) The diamond powder is purified, boiled, and quenched. The potassium phosphate aqueous solution with a concentration of 2.7mol / L is used for the boiling treatment. The quenching treatment adopts an instantaneous temperature spray quenching equipment, with a heating rate of 200°C / min and a cooling rate of 670 ℃ / min, and then crushed in a high-impact shearing machine, the punch frequency of high-impact shear crushing is 160, and polygonal diamond powder is obtained;

[0034] (3) Weigh iron-based alloy powder and polygonal diamond powder according to the mass percentage of 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com