Test system for kilowatt-scale reversible solid oxide fuel cell-electrolysis cell

A solid oxide and fuel cell technology, applied in the direction of solid electrolyte fuel cells, fuel cells, fuel cell grouping, etc., can solve problems such as the kilowatt-level reversible solid oxide fuel cell-electrolyzer test system that has not been found, and achieve reduction The effect of a small thermal shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Carry out the thermal test of the kilowatt-level reversible solid oxide fuel cell-electrolyzer test system.

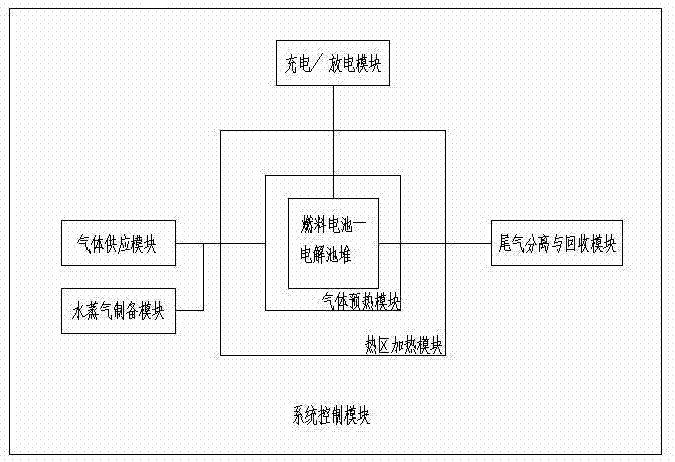

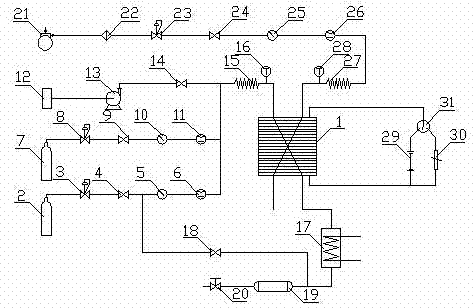

[0057] The components of the reversible solid oxide fuel cell-electrolyzer test system are in accordance with Figure 1 to Figure 4Connect and integrate, each module equipment can work normally after debugging, each signal monitoring and data recording function is accurate under the overall control of the main program in the background, the gas is preheated and connected to the exhaust gas treatment device, waiting for the gas source and other preparations After completion, the thermal test experiment can be carried out.

[0058] First, set the temperature rise program through the hot zone heating module, that is, heat the hot zone to 750°C at a heating rate of 3°C / min and then maintain the temperature; secondly, adjust the gas flow rate through the human-computer interface, H 2 The air flow adjustment range is from 0~75L / min, and at the same time according to ...

Embodiment 2

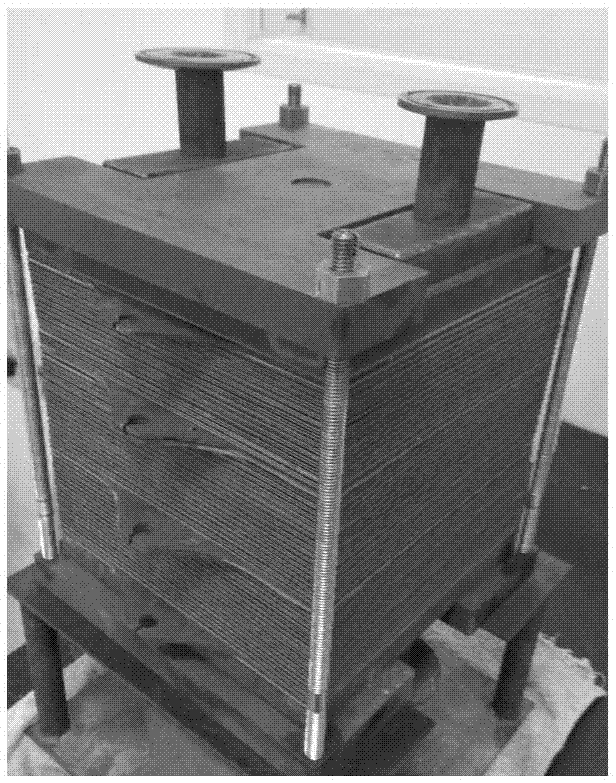

[0061] 30 pieces 200*200cm 2 Fuel cell stack power generation performance test.

[0062] Step 1: Put 30 pieces of 200*200cm 2 Put the fuel cell stack into the hot zone and connect the gas inlet and outlet pipelines, such as Figure 6 As shown, after the air tightness test, the temperature is maintained after heating to 750°C at a heating rate of 2°C / min.

[0063] Step 2: Slowly adjust N 2 After the flow rate reaches 6-9L / min, purge for about 30 minutes, according to H 2 : Air = 1:2.5 (volume ratio) into the gas to restore the battery stack, the reduction time after 3-4 hours until the average voltage of a single battery reaches 1.1-1.2V, at this time it is considered that the battery stack is fully restored.

[0064] Step 3: Adjust different H 2 : Air flow, start the electronic load for program testing, as the current continues to increase, the total voltage of the battery stack decreases from the open circuit voltage, and a large amount of heat and water vapor are genera...

Embodiment 3

[0066] 10 pieces 200*200cm 2 Joint test of fuel cell-electrolyzer stack power generation and electrolytic hydrogen production system.

[0067] Step 1: Put 10 pieces of 200*200cm 2 Put the fuel cell-electrolyzer stack into the hot zone and connect the gas inlet and outlet pipelines, such as Figure 8 As shown, after the air tightness test, the temperature is maintained after heating to 750°C at a heating rate of 2°C / min.

[0068] Step 2: Slowly adjust N 2 After the flow rate reaches 2-3L / min, purge for about 30 minutes, according to H 2 : Air = 1:2.5 (volume ratio) into the battery-electrolytic cell stack reduction, the reduction time after 3-4 hours until the average voltage of a single battery reaches 1.1-1.2V, at this time it is considered that the battery-electrolytic cell stack reduction is sufficient .

[0069] Step 3: In the power generation mode of the battery stack, start the electronic load to carry out the automatic test of the program. The total voltage of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com